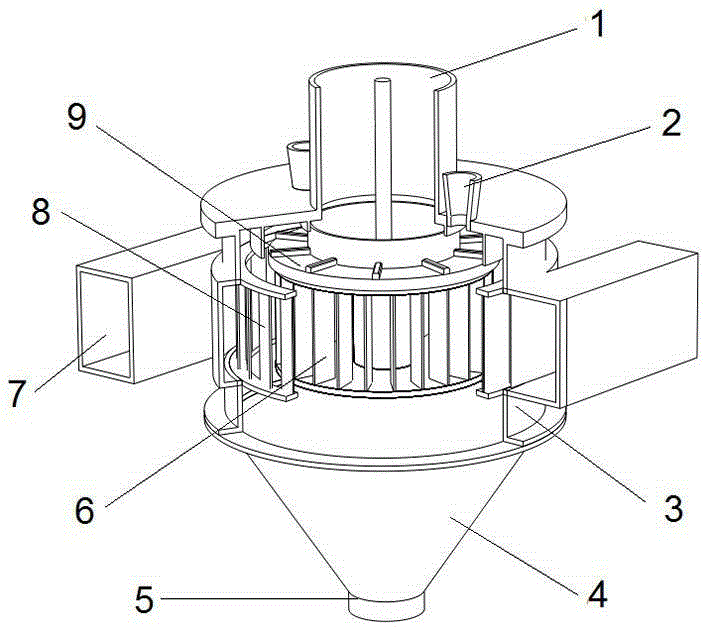

Vortex air classifier non-radial curved blade rotation cage

An air classifier, non-radial technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problem of unfavorable flow field stable fine powder, intensified airflow reverse rotation, rotation The impact of cage blades and other issues can be improved to improve the classification accuracy and fine powder yield, inhibit the formation of air vortices, and reduce the velocity gradient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0019] An implementation case of the present invention: select calcium carbonate as the raw material to be classified to carry out material classification, and its particle size composition is as shown in Table 1.

[0020] Table 1 calcium carbonate raw material particle size distribution table

[0021] Particle size range (μm) <1.8

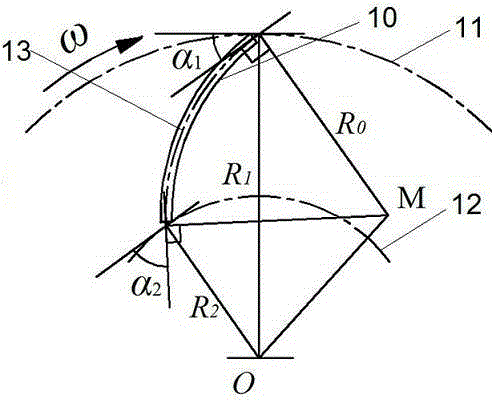

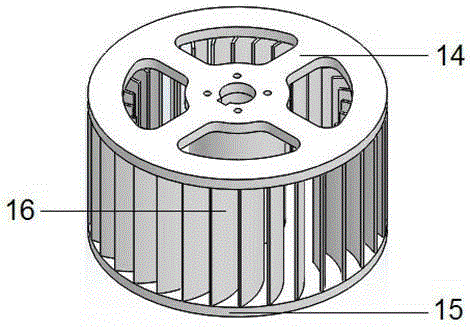

[0022] The experiment adopts the traditional radial straight blade rotor cage and the non-radial arc blade rotor cage designed by the present invention respectively, and the rotor cage blade inlet installation angle of the non-radial arc blade is α 1 Set to 45°, the installation angle of the rotor blade outlet α 2 Set to 85°. The graded products obtained under the structure of the non-radial circular arc blade cage are compared with the graded products of the traditional radial straight blade cage. diameter between 28μm-70μm) content decreased. That is to say, the particle size distribution of the fine powder product obtained by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com