A kind of protective film that can be formed by thermocompression and preparation method thereof

A technology of thermoforming and protective film, applied in chemical instruments and methods, lamination, lamination devices, etc. Industrialized production, good exhaust, not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a thermocompression-formable protective film, comprising the following steps:

[0045] Preparing the upper PET layer 22 and the lower PET layer 24: stamping the PET base material to obtain the upper PET layer 22 and the lower PET layer 24 respectively;

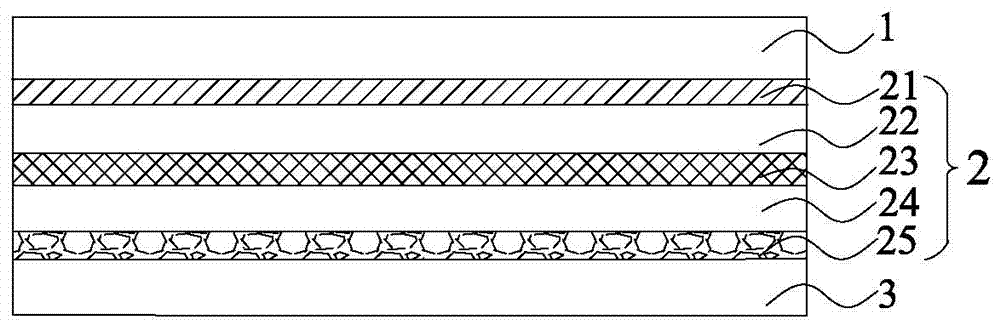

[0046] Preparing the UV curable layer 21: coating the radiation curable material on the upper surface of the upper PET layer 22 with a micro-concave anilox roller, and the radiation curable material is cured by a UV light source to form the UV curable layer 21;

[0047] Preparation of the composite layer: coating the acrylic adhesive layer 23 on the lower surface of the upper PET layer 22, placing it in an oven to bake, and hot-pressing the upper surface of the lower PET layer 24 and the acrylic adhesive layer to obtain a composite layer;

[0048] Prepare the silica gel layer 25: apply the silica gel layer 25 on the lower surface of the lower PET layer 24, and bake the silica gel layer 25 in an ov...

Embodiment 2

[0070] Such as figure 1 Shown, the difference between this embodiment and embodiment 1 is:

[0071] In this embodiment, the radiation time of the UV curable layer 21 is 2min, the radiation temperature is 120°C, and the light intensity of the UV light source is 700mJ / cm 2 , the thickness of the UV hardened layer 21 is 2 μm, the light transmittance is 94%, the surface hardness is 5H, and the wear resistance is measured by using 0000# steel wool with a load of 2kg / 25mm, and no scratches are found after 10 times.

[0072] In this embodiment, the radiation-curable material for preparing the UV curable layer 2121 is UV-curable anti-pollution and easy-to-clean resin of the type UA-860 produced by Zhongshan Jieshida Fine Chemical Co., Ltd., and its viscosity is 1800cP / 25°C.

[0073] Further, in the step of preparing the upper PET layer 22 and the lower PET layer 24, the thickness of the upper PET layer 22 is 50 μm, and the thickness of the lower PET layer 24 is 38 μm.

[0074] Furth...

Embodiment 3

[0084] Such as figure 1 Shown, the difference between this embodiment and embodiment 1 is:

[0085] In this embodiment, the radiation time of the UV curable layer 21 is 5 minutes, the radiation temperature is 80° C., and the light intensity of the UV light source is 400 mJ / cm 2 , the thickness of the UV hardened layer 21 is 5 μm, the light transmittance is 94%, the surface hardness is 5H, and the wear resistance is measured by using 0000# steel wool with a load of 2kg / 25mm, and no scratches after 10 times.

[0086] In this embodiment, the radiation-curable material for the UV curable layer 2121 is UV-curable anti-pollution and easy-to-clean resin produced by Zhongshan Jieshida Fine Chemical Co., Ltd. with a viscosity of 1700 cP / 25° C., model UA-860.

[0087] Further, in the step of preparing the upper PET layer 22 and the lower PET layer 24, the thicknesses of the upper PET layer 22 and the lower PET layer 24 are both 44 μm.

[0088] Further, in the step of preparing the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com