Built-in particle damping shock absorber type wheel for railway vehicle

A particle damping and rail vehicle technology, which is applied in the field of rail vehicle vibration reduction, can solve the problems of shortening, large range, and increased life of wheelset wear, and achieves the effect of reducing additional impact force, obvious damping effect, and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

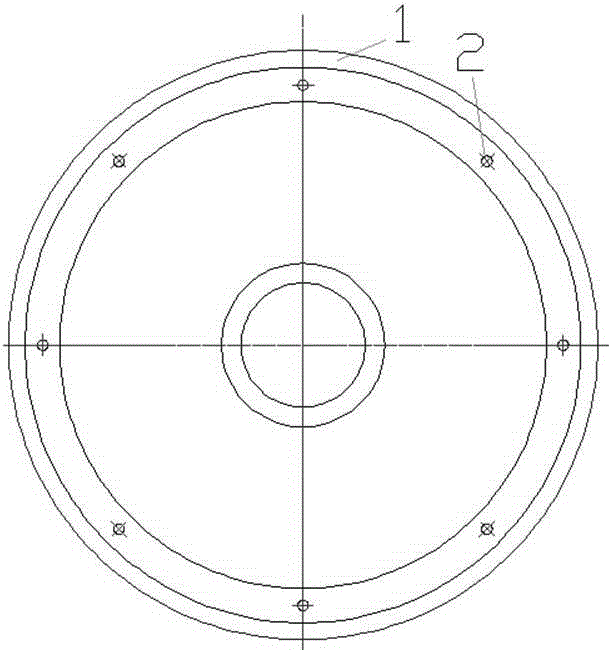

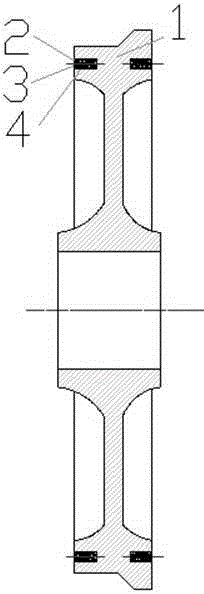

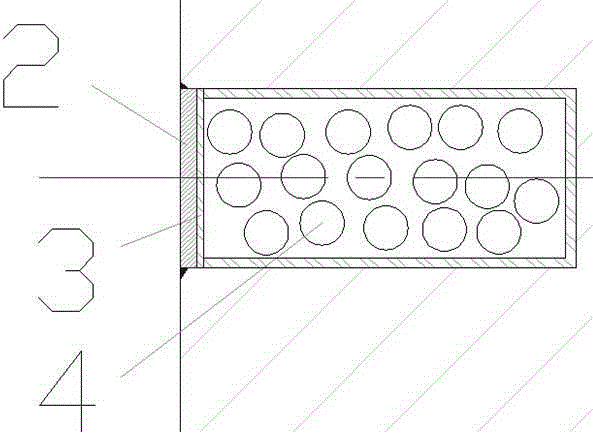

[0017] Embodiment 1: A wheel with built-in particle damping shock absorber for rail vehicles, including a rigid wheel 1, the rigid wheel 1 is integrally rolled with carbon steel, and a plurality of annular openings are symmetrically arranged on the outer edge of the rigid wheel 1 Grooves, the number of annular opening grooves is 4X2, 5X2, 8X2, etc., and are evenly distributed on the outer edge of the rigid wheel 1; the wear-resistant rubber interlayer 3 is installed in the outer edge opening groove of the rigid wheel 1, and the two are interference fit; The damping particles 4 are located in the opening groove on the outer edge of the rigid wheel 1, that is, the wear-resistant rubber interlayer 3 is filled with a certain amount of damping particles 4 and a small amount of lubricating oil, and the quantity, size and material are selected according to the route; Rigid wheel 1 outer edge opening groove welding sealing treatment that wear-resistant rubber interlayer 3 is housed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com