Synchronous belt wheel packaging device

A technology of synchronous pulleys and packaging equipment, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of low work efficiency, large labor hours, high labor intensity, etc., to reduce labor intensity, improve work efficiency, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

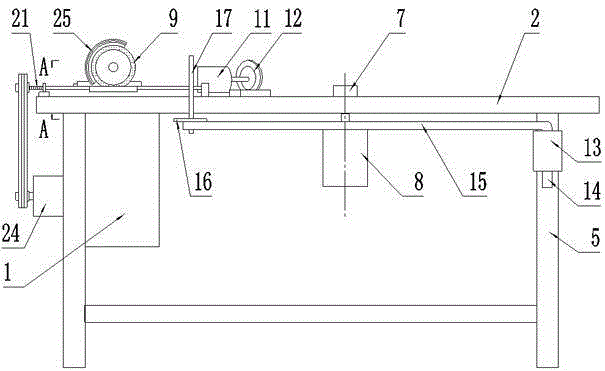

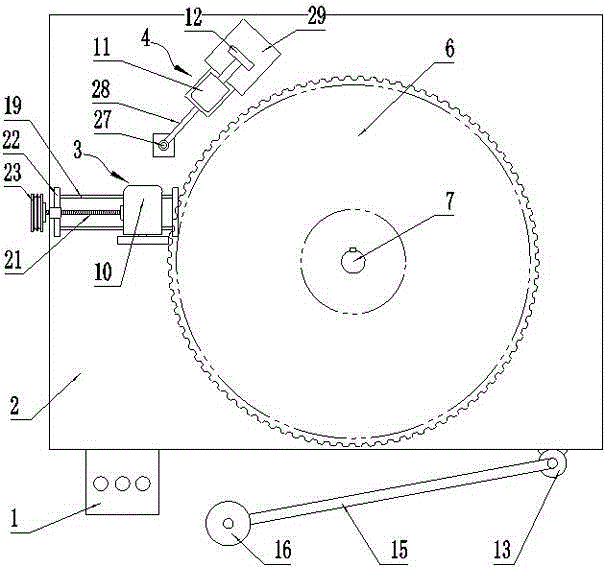

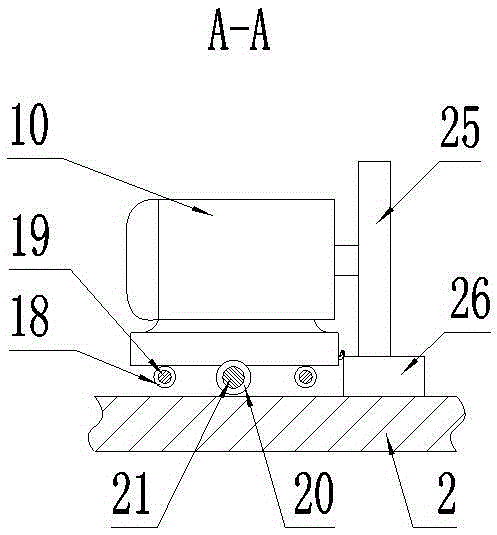

[0022] Such as figure 1 , 2 A kind of synchronous pulley packaging equipment shown in , 3, comprises control cabinet 1, workbench 2, paint removing device 3 and oiling device 4, described workbench 2 is provided with support leg 5 below, and is provided with synchronous pulley above 6 matched mandrel 7, said mandrel 7 is installed vertically on the workbench 2 and is driven by the first motor 8 below the workbench 2, and the paint removal device 3 includes a steel brush 9 arranged above the workbench 2 , the steel brush 9 is driven by the second motor 10; the oiling device 4 includes the oil brush 12 driven by the third motor 11; the central axes of the steel brush 9 and the oil brush 12 are horizontally arranged, so The distance between the edges of the steel brush 9 and the oil brush 12 and the mandrel 7 matches the radius of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com