Heat-resistant concrete and preparation method thereof

A heat-resistant concrete and admixture technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as casualties, property and personnel loss, property loss, etc. The effect of improving the service life and working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

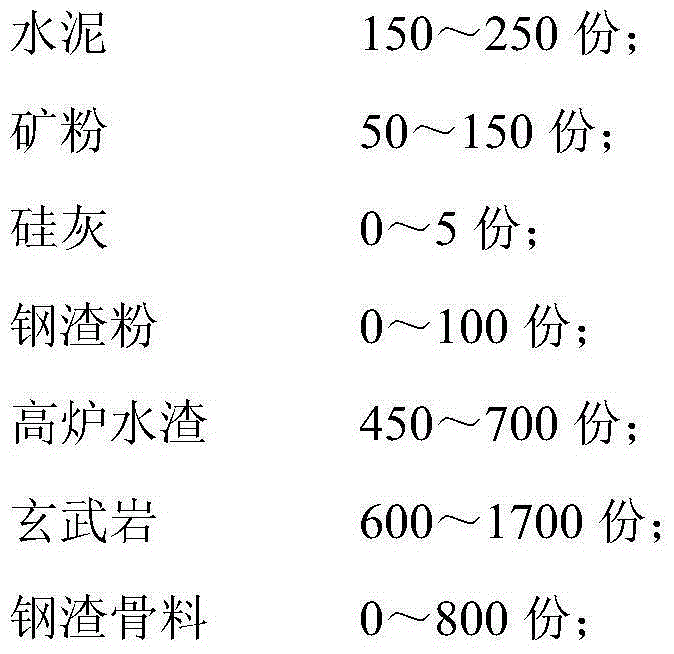

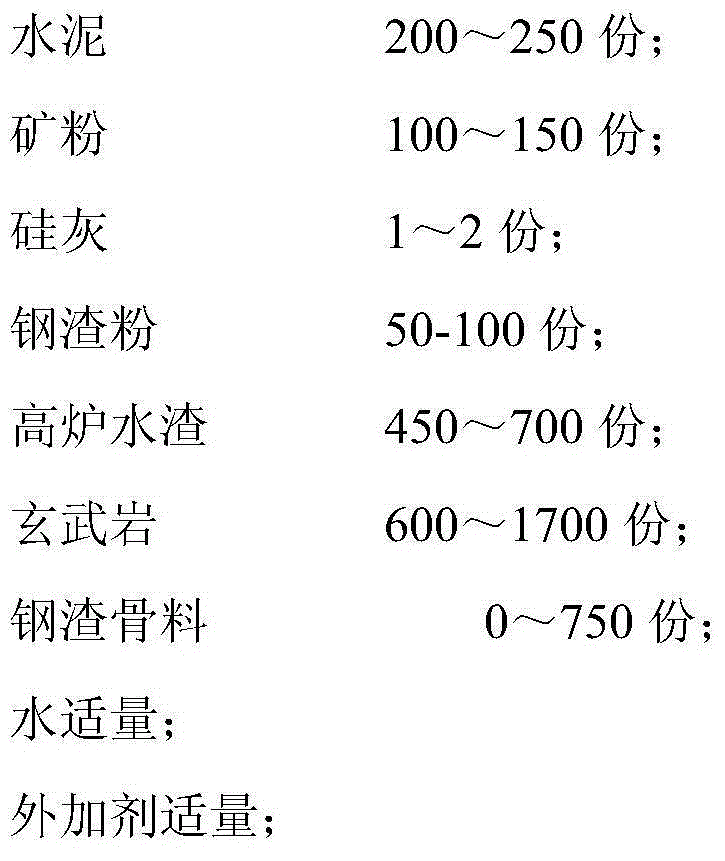

Method used

Image

Examples

preparation example Construction

[0065] The preparation process used in the embodiment is the preparation process of ordinary concrete, that is, the aggregate (steel slag aggregate, blast furnace slag, basalt) is mixed first, and then the powder (cement, mineral powder, steel slag powder, Silica fume) is poured in, after stirring, add water and liquid admixture and continue to stir evenly to become the heat-resistant concrete of the present invention.

[0066] According to "YB / T4252-2011 Technical Specification for Application of Heat-resistant Concrete", the technical indicators are tested. The residual strength adopts the method in this standard: after the standard curing, the 100×100×100mm concrete test block is placed in an electric heating constant temperature drying oven, and dried at 110°C±5°C for 24h. The dried test piece is heated in an electric furnace, and the temperature is raised to 700°C at an average speed of 2°C / min to 3°C / min. After a constant temperature of 3 hours, it is cooled to room temp...

Embodiment 1

[0069] Mix 500 parts of blast furnace slag, 1050 parts of basalt, and 650 parts of steel slag aggregate, and stir for 15 seconds. Then pour 250 parts of cement, 150 parts of mineral powder, and 100 parts of steel slag powder, stir for 15 seconds, then add 160 parts of water, stir evenly (stirring time 2min), and the slump is 50mm. The prepared concrete was made into 2 groups (6 pieces) of 100×100×100mm test blocks, and the experiment was carried out after 7 days of curing. One group was subjected to the compressive strength test, and the other group was subjected to the residual strength test. The 7d compressive strength is 32.5MPa, and the 7d residual strength is 29.6MPa.

Embodiment 2

[0071] Mix 450 parts of blast furnace slag, 700 parts of basalt, and 750 parts of steel slag aggregate, and stir for 15 seconds. Then pour 200 parts of cement, 120 parts of mineral powder, and 50 parts of steel slag powder, and stir for 15 seconds, then add 2.6 parts of liquid water reducer, add 120 parts of water and stir for 10 seconds, and then pour it into the dry concrete. Stir evenly (stirring time 2min), the slump is 30mm. The prepared concrete was made into 2 groups (6 pieces) of 100×100×100mm test blocks, and the experiment was carried out after 7 days of curing. One group was subjected to the compressive strength test, and the other group was subjected to the residual strength test. The 7d compressive strength is 40.1MPa, and the 7d residual strength is 31.9MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com