Thermoplastic elastomer composition for covering nylon material

A technology of thermoplastic elastomer and composition, applied in the field of thermoplastic elastomer materials, to achieve good coating and bonding performance, improved oil corrosion resistance, and significant economic and social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

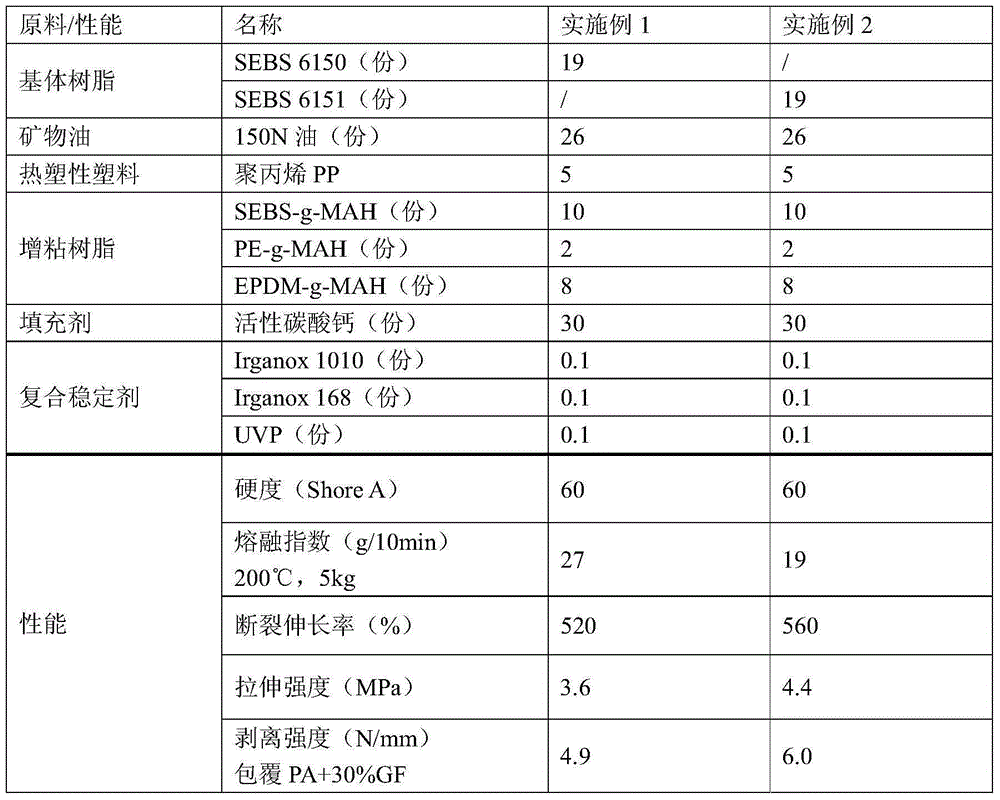

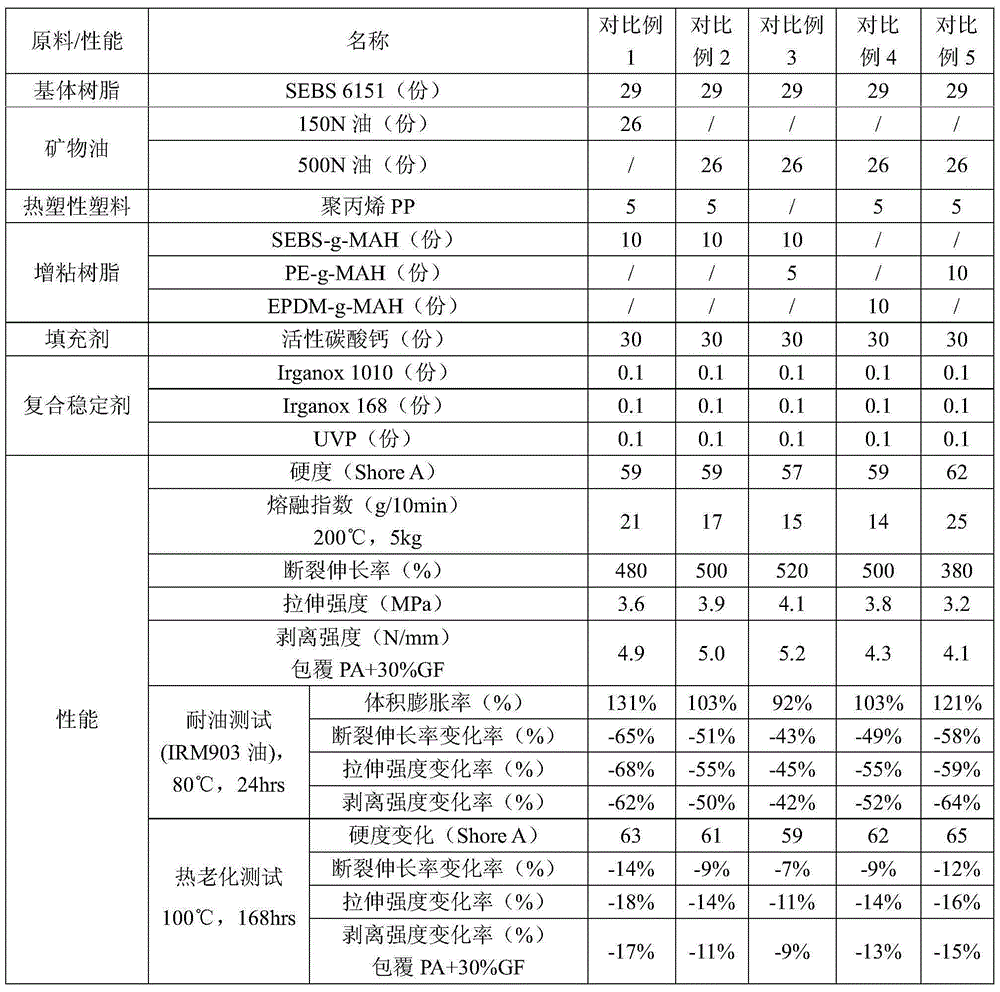

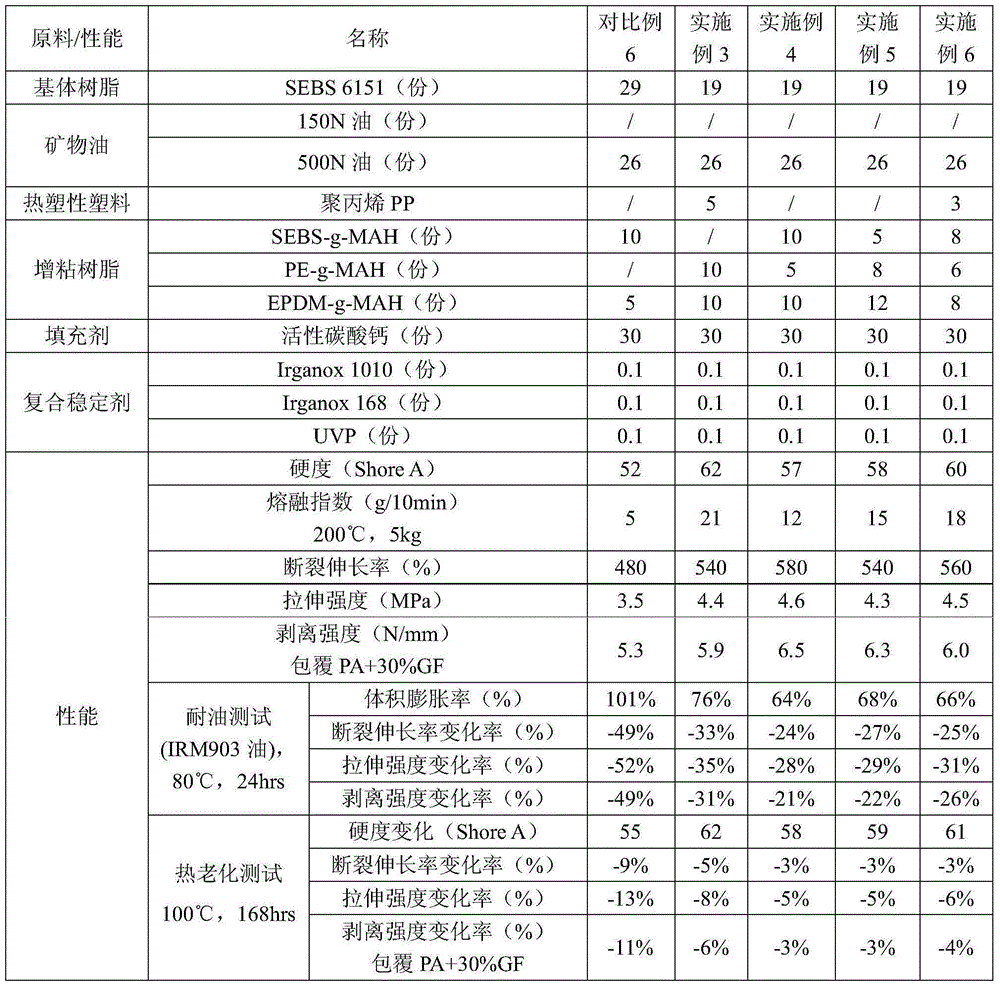

[0037] According to the embodiment formula listed in Table 1 ("parts" in the table all refer to parts by weight, the same below), at first SEBS resin and mineral oil are fully mixed in a prescribed ratio, and mineral oil is completely absorbed by SEBS resin to obtain Oil-extended SEBS, and then mix the oil-extended SEBS with thermoplastics, tackifying resins, fillers, and composite stabilizers in a high-speed mixer. The mixed materials are evenly fed into the twin-screw extruder by the feeder. The temperature of the twin-screw extruder is set at 190-220°C, the screw speed is set at 280 rpm, and the feeding speed is set at Set at 30 rpm. After twin-screw high-speed shearing, mixing and plasticizing, extruding from the head of the extruder, drawing, cooling, pelletizing, drying, and then punching boards for performance testing, the results are shown in Table 1.

[0038] Table 1

[0039]

[0040] As can be seen from the peel strengths of the thermoplastic elastomers prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com