Al-Mg alloy porous material and preparation method thereof

A technology of porous materials and metal materials, which is applied in the field of Al-Mg alloy porous materials and its preparation, can solve the problems that the research of porous materials has not been paid attention to, and achieve excellent chloride corrosion resistance, high open porosity, and abundant connected pores Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

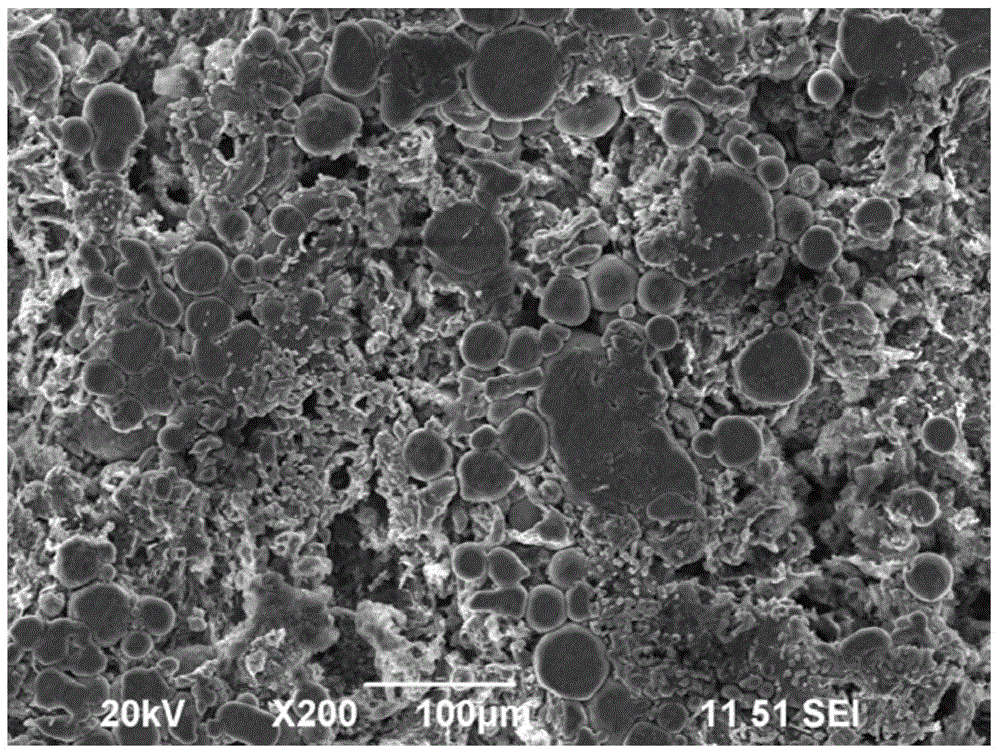

[0027] Mix Al powder with a particle size of 100-150 mesh and Mg powder with a particle size of 100-150 mesh for 10 hours at a mass ratio of 6.25:3.75; press-form the mixed powder of the above-mentioned Al powder and Mg powder, Hold the pressure for 90 seconds under a molding pressure of 50MPa, and obtain a compact after pressing; place the compact in a vacuum sintering furnace for sintering, and the vacuum degree is 10 -3 Pa, the sintering process consists of three stages: the first stage, the sintering temperature is raised from room temperature to 120°C, the heating rate is controlled at 10°C / min, and the temperature is kept at 120°C for 30min; the second stage, the sintering temperature is raised to 350°C ℃, the heating rate is controlled at 10 °C / min, and the temperature is kept at 350 °C for 90 min; in the third stage, the sintering temperature is raised to 435 °C, the heating rate is controlled at 5 °C / min, and the temperature is kept at 435 °C for 240 min; after sinteri...

Embodiment 2

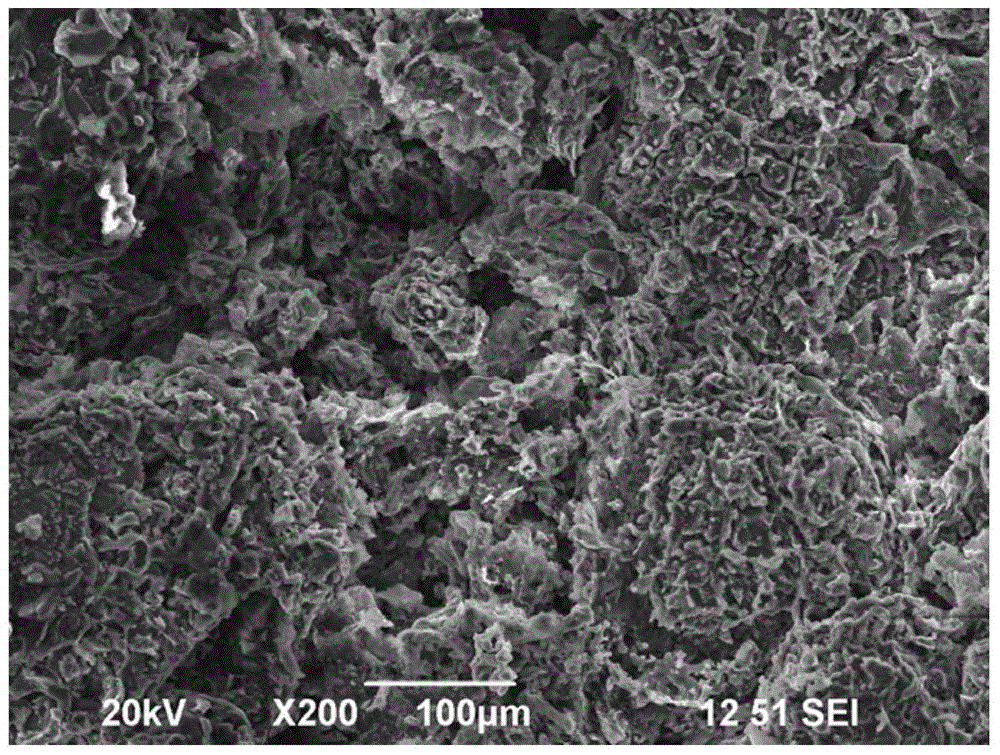

[0029] Mix Al powder with a particle size of 100-150 mesh and Mg powder with a particle size of 100-150 mesh at a mass ratio of 4.4:5.6 for 10 hours; press-form the mixed powder of the above-mentioned Al powder and Mg powder, Hold the pressure for 90 seconds under a molding pressure of 50MPa, and obtain a compact after pressing; place the compact in a vacuum sintering furnace for sintering, and the vacuum degree is 10 -3 Pa, the sintering process consists of three stages: the first stage, the sintering temperature is raised from room temperature to 120°C, the heating rate is controlled at 10°C / min, and the temperature is kept at 120°C for 30min; the second stage, the sintering temperature is raised to 350°C ℃, the heating rate is controlled at 10 °C / min, and the temperature is kept at 350 °C for 90 min; in the third stage, the sintering temperature is raised to 435 °C, the heating rate is controlled at 5 °C / min, and the temperature is kept at 435 °C for 240 min; after sintering...

Embodiment 3

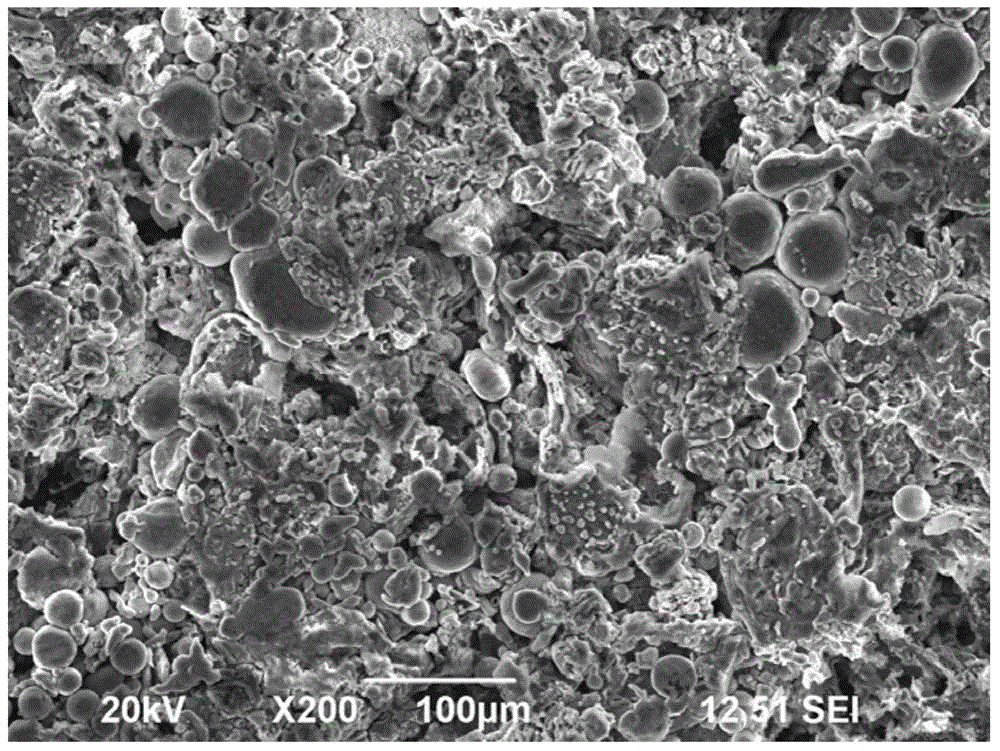

[0031] Mix Al powder with a particle size of 200-250 mesh and Mg powder with a particle size of 200-250 mesh at a mass ratio of 6.25:3.75 for 10 hours; press-form the mixed powder of the above-mentioned Al powder and Mg powder, Hold the pressure for 90 seconds under a molding pressure of 50MPa, and obtain a compact after pressing; place the compact in a vacuum sintering furnace for sintering, and the vacuum degree is 10 -3 Pa, the sintering process consists of three stages: the first stage, the sintering temperature is raised from room temperature to 120°C, the heating rate is controlled at 10°C / min, and the temperature is kept at 120°C for 30min; the second stage, the sintering temperature is raised to 350°C ℃, the heating rate is controlled at 10°C / min, and kept at 350°C for 60 minutes; in the third stage, the sintering temperature is raised to 425°C, the heating rate is controlled at 5°C / min, and kept at 425°C for 210 minutes; after sintering The sintered Al-Mg alloy porous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com