Semi-backdraft type small-size fuel oil and fuel gas hot water boiler

A gas-fired hot water, small-scale technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of inconvenient observation of burner working conditions, impact on burner service life, and inability to effectively reduce content, etc. To achieve the effect of shortening the length of the smoke pipe, prolonging the residence time and reducing the back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

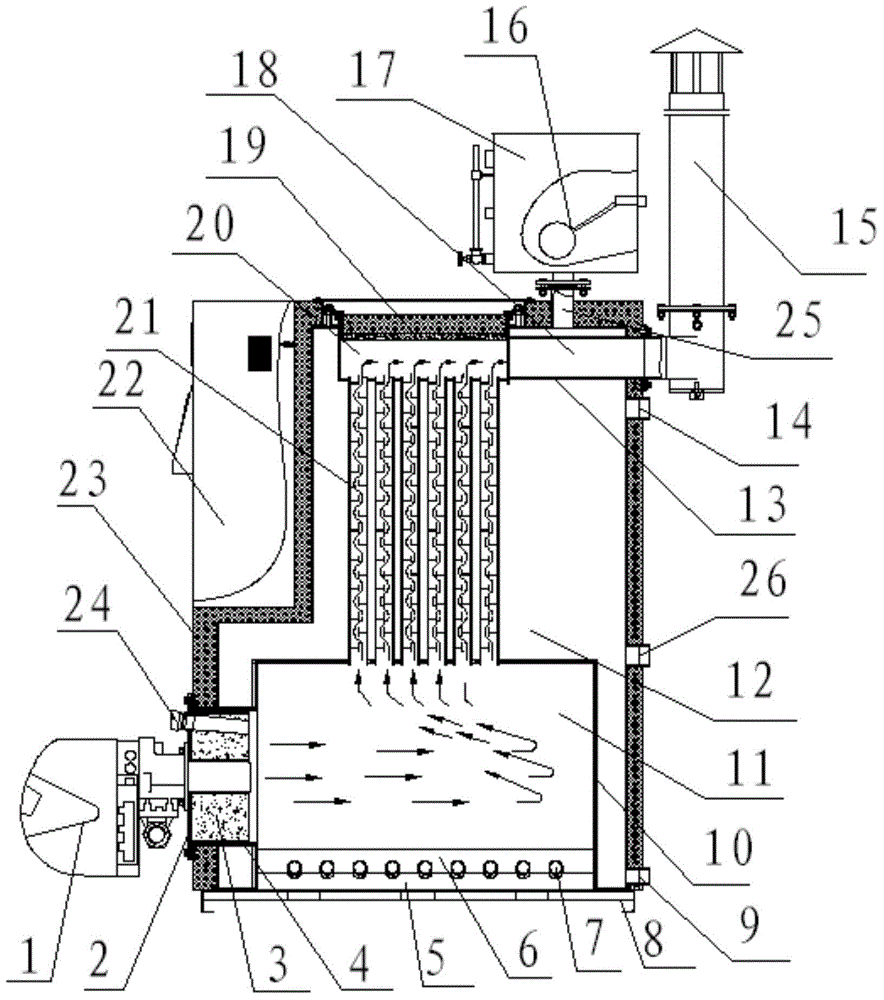

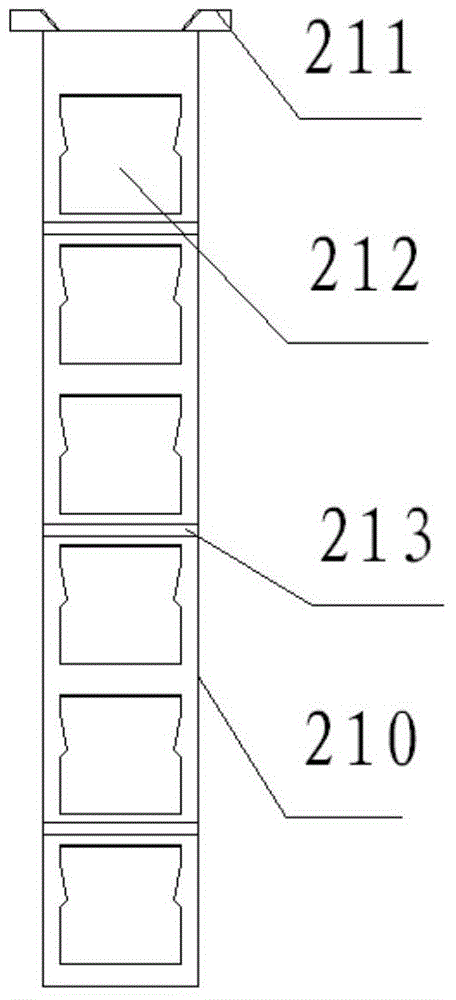

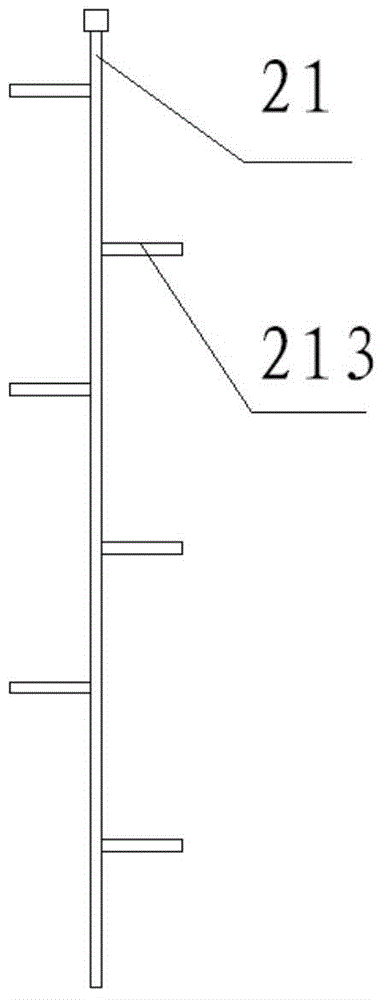

[0021] Such as figure 1 , 2 , 3, a semi-backfired small oil-fired gas-fired hot water boiler, including a base 8, a boiler shell 23, an outer tank 13, an inner tank 10, and a burner 1, and the closed space formed by the inner tank 10 is a combustion chamber 11 , the combustion chamber 11 is connected to the upper smoke chamber 20 through the smoke pipe 21, and the upper smoke chamber 20 communicates with the chimney 15 through the flue 18, and the closed space between the outer tank 13 and the inner tank 10 is a water chamber 12, and the upper part of the water chamber 12 It is connected with an expansion tank 17, which is cha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap