In-situ online collection analysis meter and method for aerosol carbonaceous components

A collection and analysis, aerosol technology, applied in the direction of material analysis, material analysis through optical means, instruments, etc., can solve the problems of slow heating, inability to comprehensively reflect the blackness of the film, waste of carrier gas use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Below in conjunction with accompanying drawing, further describe the present invention through embodiment, but do not limit the scope of the present invention in any way.

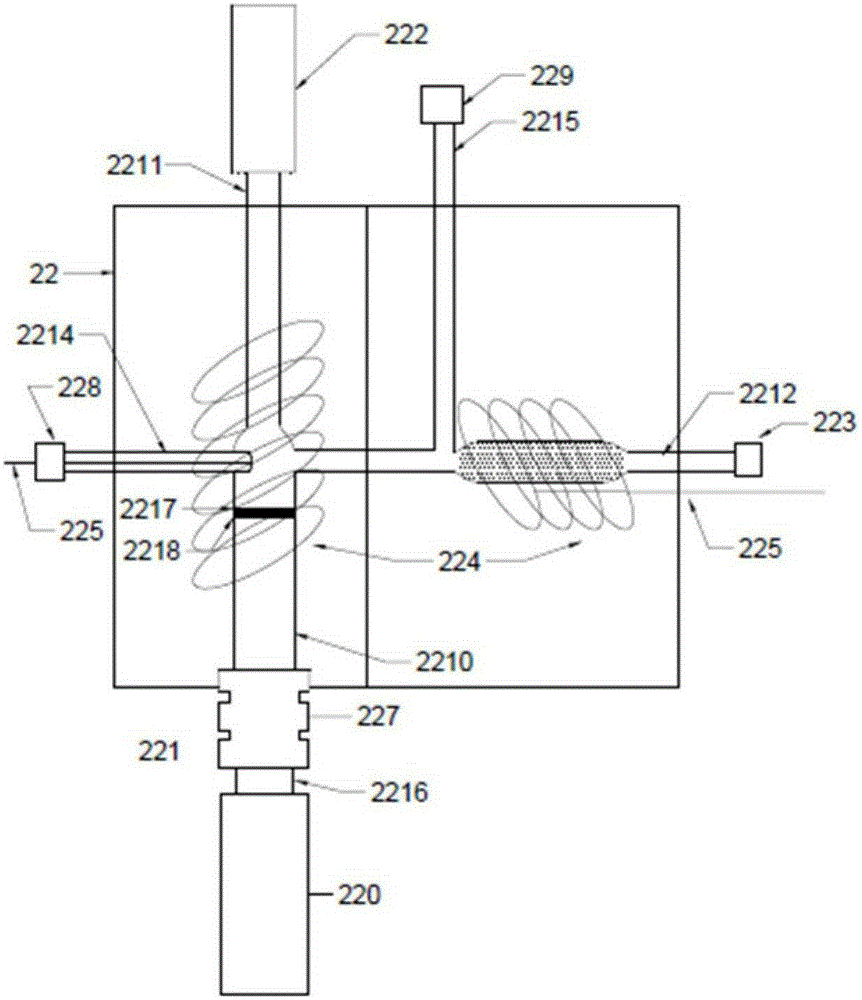

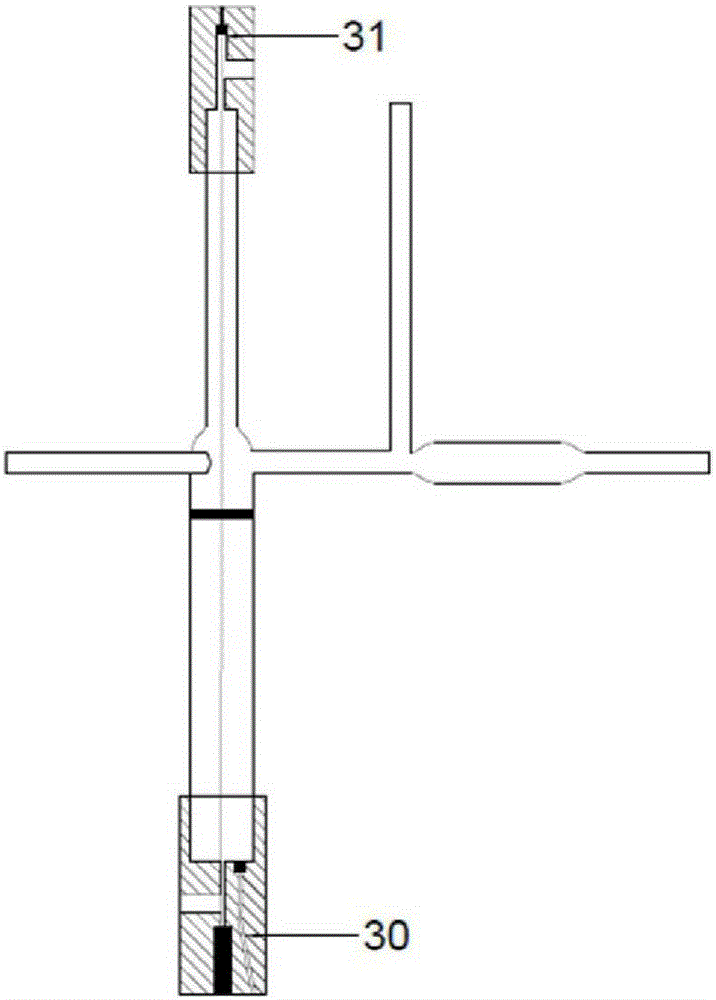

[0070] The invention provides an in-situ online collection and analysis instrument for aerosol carbonaceous components. No other structures except the quartz film are set in the laser light path, which ensures the accuracy of the light path; Calibrate at the same point to comprehensively reflect the change of film blackness; the design of the valve body greatly reduces the quantitative error of the methane internal standard gas, ensures the stability of the internal standard gas, and improves the accuracy of EC and OC measurement results; the gas circuit design ensures During the analysis stage, the composition of the carrier gas in the system is constant, which ensures the stability of the system background.

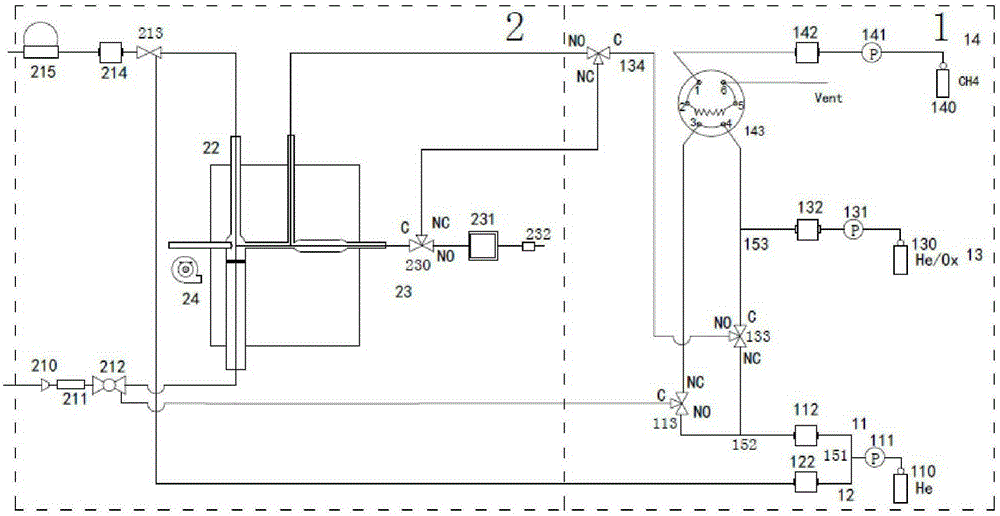

[0071] Such as figure 1 As shown, the aerosol carbonaceous component in-situ online colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com