A processing quality control method for cylinder head parts

A technology of processing quality and control method, applied in the direction of program control, computer control, general control system, etc., can solve the problems of reduced enterprise profit, low inspection efficiency, long process route, etc., to avoid inefficiency and cost increase, obvious The effect of cost advantage and high utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

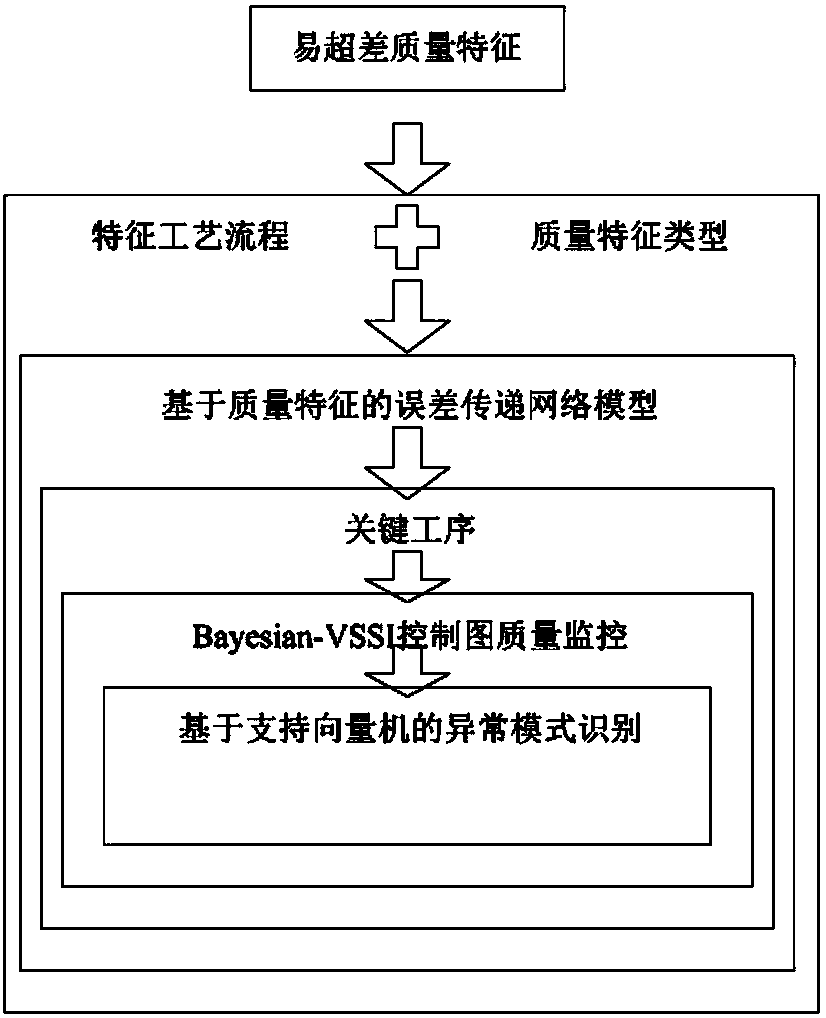

[0079] Such as figure 1 As shown, the quality control method of the present invention comprises two parts: first, set up the error transmission network model based on quality characteristic to determine the key feature that affects processing quality; monitor.

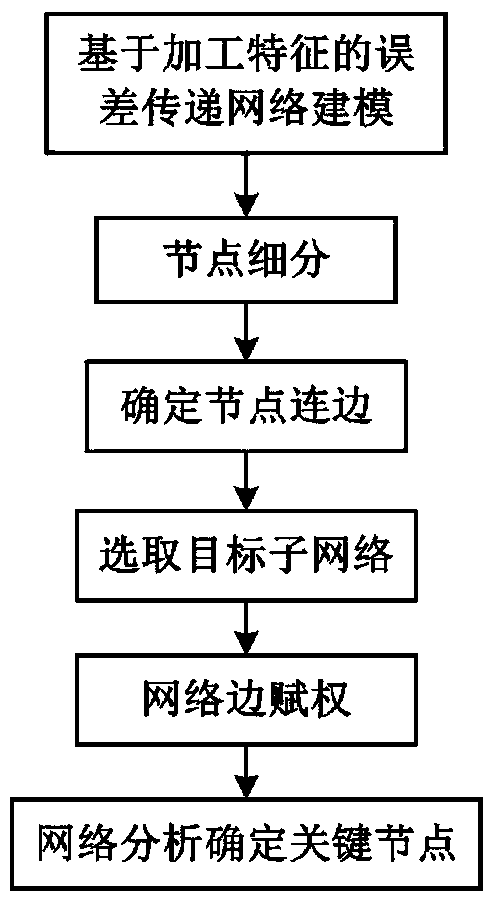

[0080] Error transfer network modeling based on quality features, such as figure 2 shown.

[0081] The flow chart of error transfer network modeling based on quality features will be described in detail below.

[0082] 4.1.1 Error transfer network modeling based on processing features

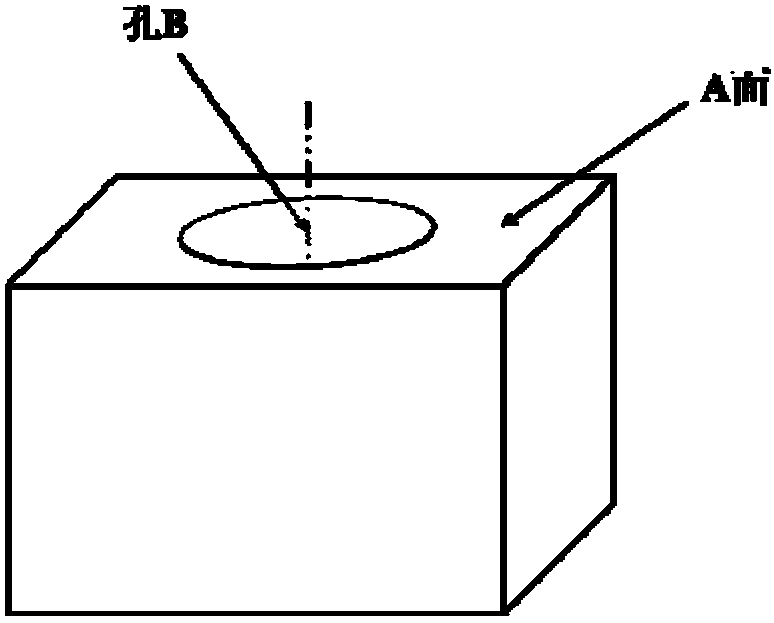

[0083] Determine the easy out-of-tolerance feature of the cylinder head machining process as the target feature (for example, establish an error transfer network model based on quality features for the MAN32_40 cylinder head, and use the coaxiality of the valve seat hole to the conduit hole as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com