Method for improving sintered nd-fe-b magnet crystal boundary

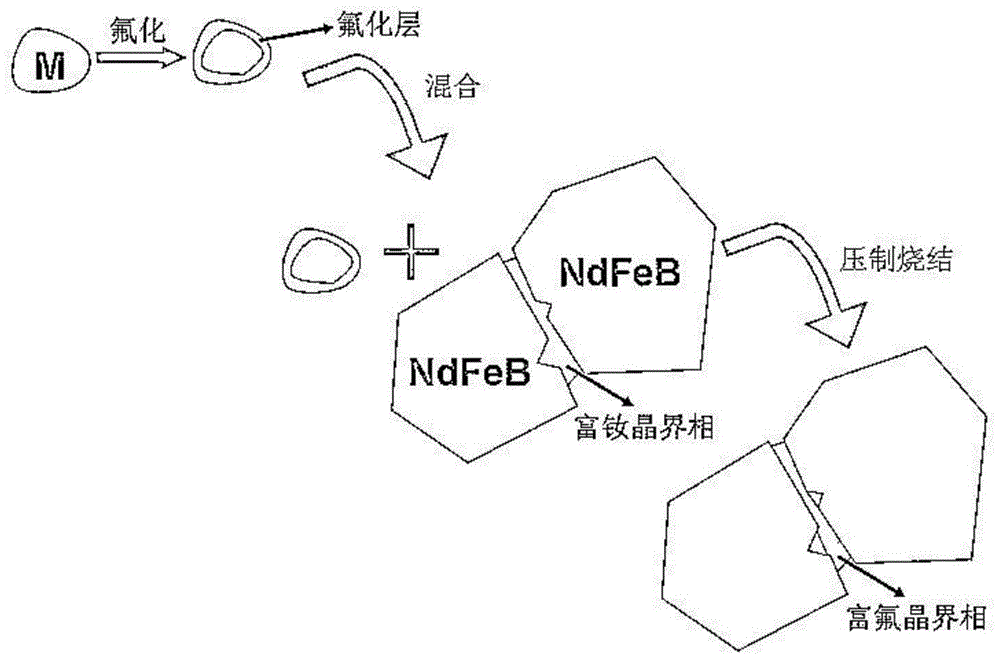

A technology of NdFeB and magnets, which is applied in the manufacture of magnetic objects, magnetic materials, inductors/transformers/magnets, etc., can solve the problems of limited doping phase effect, achieve the effect of weakening the thickness of lattice distortion and increasing the coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Cu powder with a particle size of about 3 microns is placed in the HF solution and stirred to make the surface fully react with HF and generate CuF on the surface 2 layer, separated by filtration, and dried at 200°C under vacuum. Using double alloy method and (Pr 0.25 Nd 0.75 ) 2.03 Fe 14.1 Nb 0.2 co 0.2 Al 0.3 B 1 The magnet powders are mixed, the doping amount is 0.5wt%, and they are fully mixed and pressed into blocks. After sintering and annealing, the properties are: Br=13.52Gs, Hcj=15.5kOe, (BH) max = 44.3 MOeGs.

Embodiment 2

[0030] Put metal Ga powder (average particle size is about 2.1 microns) in F 2 In the mixed gas with argon, F in the mixed gas 2 5% of volume fraction. The surface of the powder was fully reacted by gas flow for 2.5 hours. Incorporated into (Pr 0.25 Nd 0.75 ) 2.03 Fe 14.1 Nb 0.2 co 0.2 Al 0.3 B 1 In the magnet powder, the doping amount is 1wt%, and it is pressed into a block after being fully mixed. After sintering and annealing, the properties are: Br=13.67Gs, Hcj=16.3kOe, (BH) max = 44.9 MOeGs.

Embodiment 3

[0032] The metal Dy / Fe (mass ratio is 4:1) block is subjected to hydrogen breaking and jet milling to obtain Dy / Fe powder (average particle size is about 3.0 microns), which is placed in F 2 In the mixed gas with argon, F in the mixed gas 2 5% of volume fraction. The surface of the powder was fully reacted by gas flow for 1.5 hours. Incorporated into (Pr 0.25 Nd 0.75 ) 2.03 Fe 14.1 Nb 0.2 co 0.2 Al 0.3 B 1 In the magnet powder, the doping amount is 2wt%, and it is pressed into a block after being fully mixed. After sintering and annealing, the properties are: Br=13.56Gs, Hcj=17.2kOe, (BH) max = 44.7 MOeGs.

[0033] Through comparative examples, Example 1, Example 2 and Example 3, it is an effective method to improve the magnetic properties of NdFeB by using the double alloy method to properly add metal fluoride in the grain boundary, and effectively improve the magnetic properties of sintered NdFeB. Coercivity of boron magnets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com