Micron carbon fluid gas-phase bubble-making device and bubble-making method for direct carbon fuel cell

A fuel cell and bubble-making technology, which is applied in fuel cells, electrical components, circuits, etc., can solve problems such as the inability to effectively balance the solid phase residence time and reaction rate, the low output power density of small devices, and the inability to efficiently increase the mass transfer rate, etc. , to optimize physical properties, reduce turbulent flow velocity, and increase carbon concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

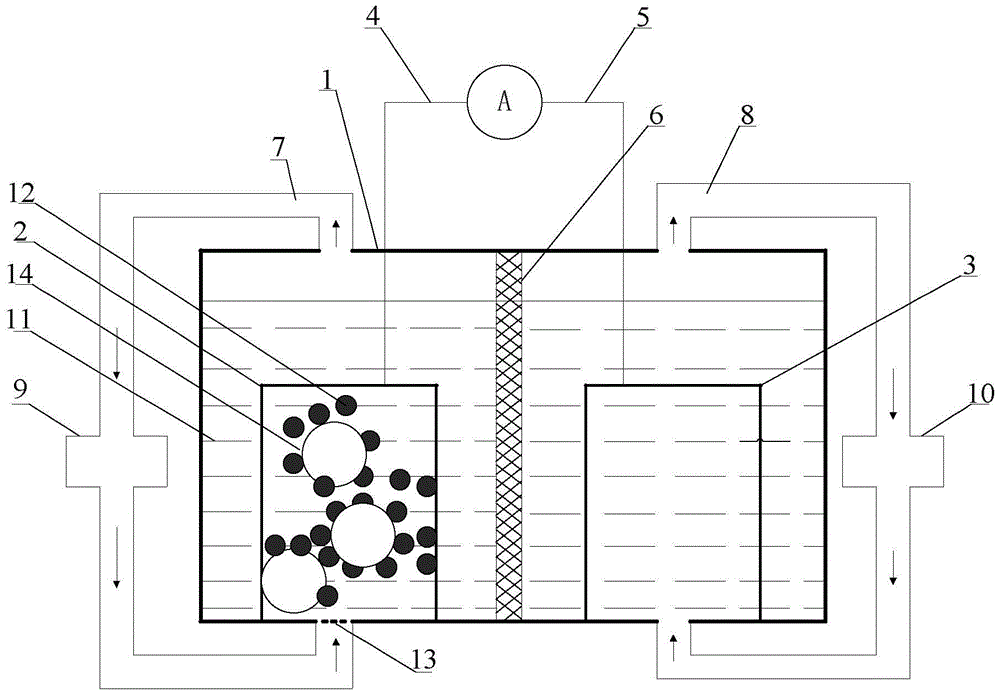

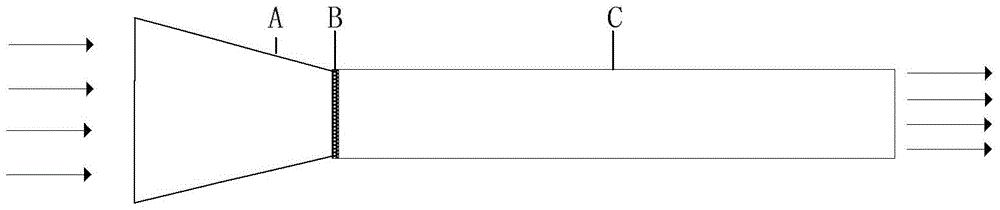

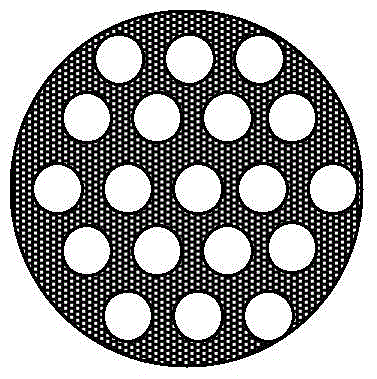

[0043] Such as figure 1 As shown, the micron carbon fluid gas-phase foaming device of the direct carbon fuel cell of the present embodiment includes: a reaction device 1, an anode plate bin 2, a cathode plate bin 3, an anode current collecting plate 4, a cathode current collecting plate 5, a microporous separator Plate 6, fluidized bed anode pipeline 7, fluidized bed cathode pipeline 8, anode gas circulation device 9, cathode gas circulation device 10, electrolyte 11, carbon particles 12 and air distribution plate 13; wherein, the reaction device 1 is filled with electrolyte 13 ; Cylindrical anode silo 2 and cathode silo 3 are respectively arranged at the bottom of reaction device 1; anode and cathode are respectively placed in anode silo 2 and cathode silo 3; The anode current collecting plate 4 and the cathode current collecting plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com