Double-passband frequency selective surface based on high-dielectric low-loss all-dielectric metamaterial

A frequency-selective surface and all-dielectric technology, applied to electrical components, circuits, waveguide devices, etc., can solve problems such as difficult expansion, failure to better meet demand, high loss, etc., and achieve polarization insensitive angle stability, good Angular stability, effects of high power handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] The dielectric constant of microwave ceramics is required to be 63, the loss tangent to be 0.003, the dual passbands are all in the Ku band, the transmittance in the passband is greater than -3dB, it is not sensitive to TE and TM polarization, and the large-angle incident performance can reach 45 °.

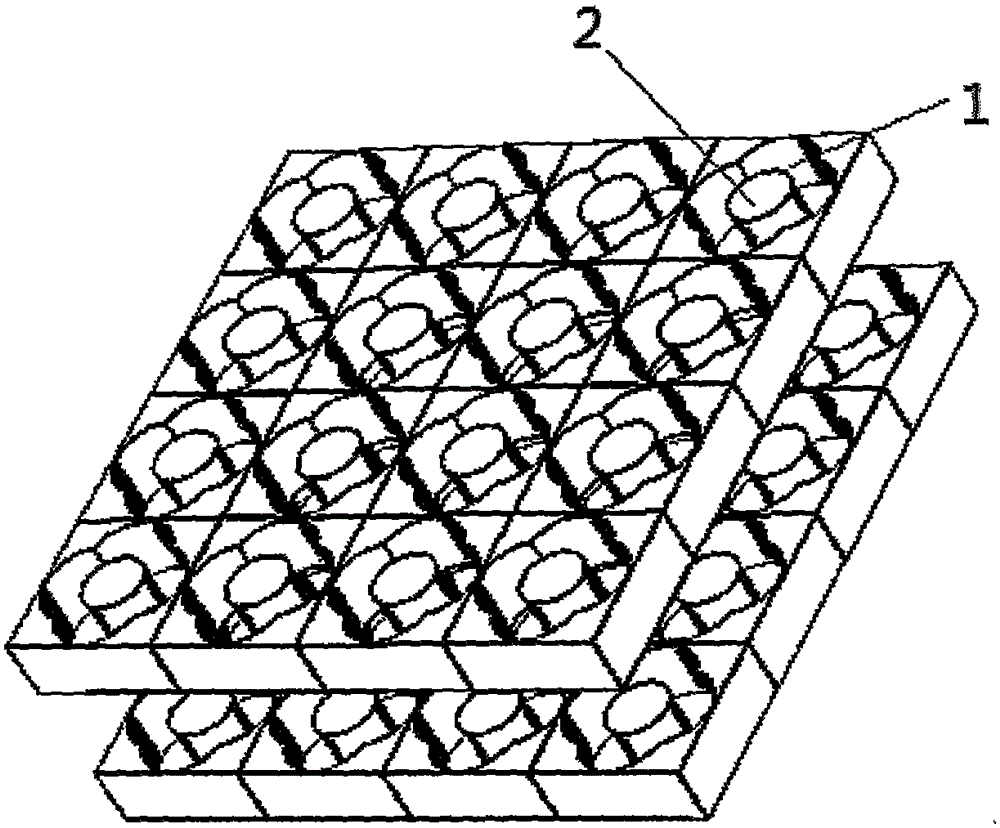

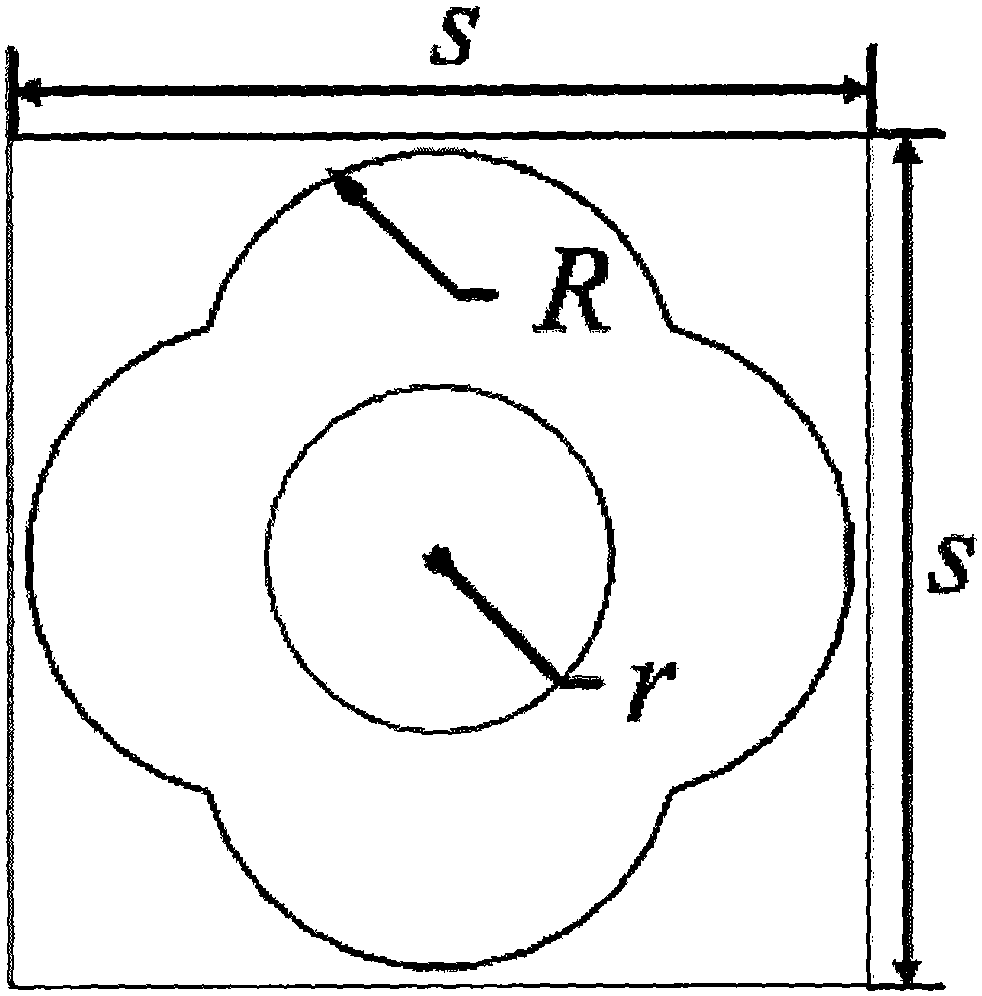

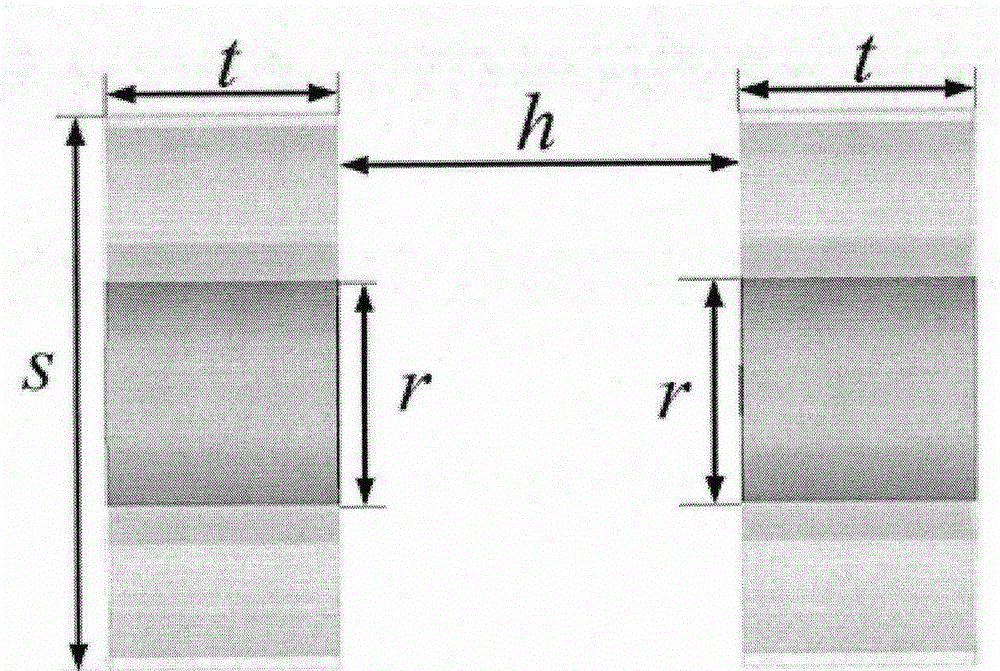

[0021] Calculate and optimize according to above-mentioned technical index, the final design structure that the implementation example of the present invention obtains is as follows: microwave ceramic thickness t=1.98mm, air interval thickness h=3.4mm, period dimension s=5.08mm, radius R=1.38 of cross-shaped circular hole mm, the dielectric resonator radius r = 1.02mm, get as Figure 1-3 A schematic diagram of the periodic structure is shown.

[0022] Calculate the transmission characteristics of the obtained dual-passband frequency-selective surface, and the results are as follows Figure 4 and Figure 5 shown. It can be seen from the figure that the frequency selecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com