Processing method of dried small shrimp snack food

A processing method and snack food technology, applied in the direction of food science, etc., can solve the problems of uneven product color, aroma and taste, affecting the quality of dried products, poor product uniformity, etc., achieve good chewiness, improve the structure of shrimp skin, and dry short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

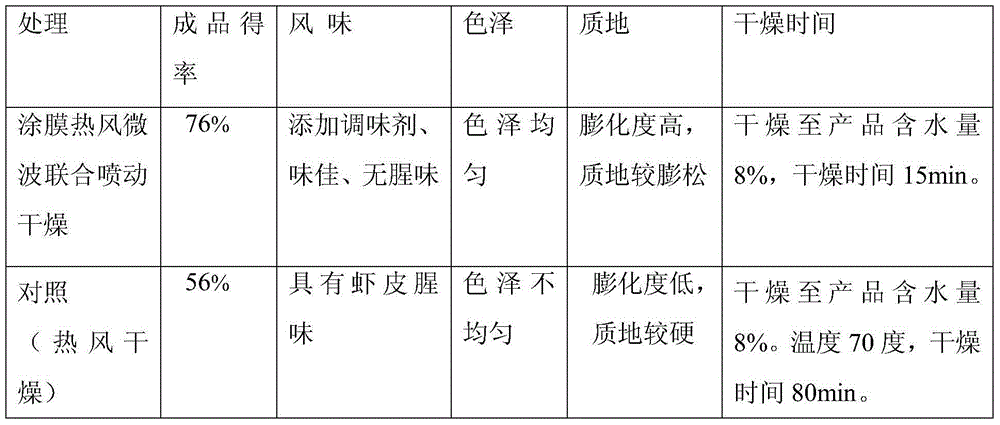

Embodiment 1

[0018] The specific steps of drying and processing dried dried shrimps into snack food are as follows:

[0019] (1) Pretreatment: After the dried shrimp skins are removed from impurities, cleaned, drained and water controlled, the dried shrimp skins are dried with hot air at a temperature of 60-70° C., so that the dried shrimp skins have a water content of 50-55 wt %; if dried shrimp skins are used as materials, This process can be eliminated.

[0020] (2) Coating film: In order to prevent the material from colliding with the wall of the drying box during spraying and causing rupture and loss, a protective film is applied on the surface of the shrimp skin to prevent shattering. At the same time, in order to improve the food taste, the coating liquid is prepared by adding seasonings to the thickener, soaking the shrimp skin in the coating liquid for 60 minutes, taking it out and draining, so that a layer of protective film is formed on the surface of the shrimp skin.

[0021] ...

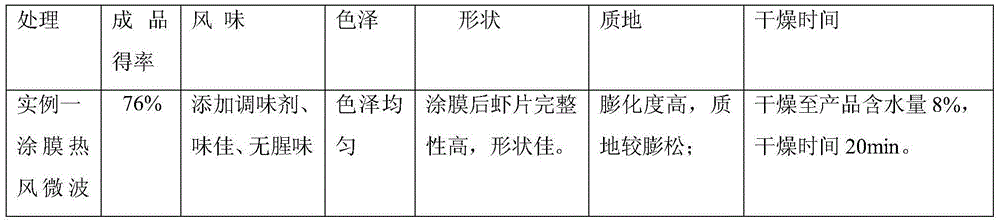

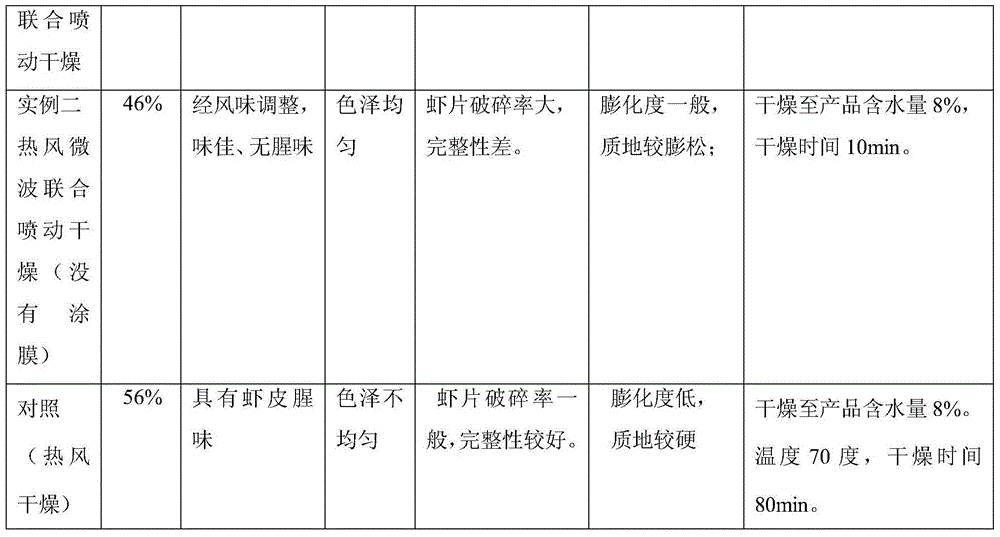

Embodiment 2

[0030] The specific steps of drying and processing dried dried shrimps into snack food are as follows:

[0031] (1) Pretreatment: After the dried shrimp skins are removed from impurities, cleaned, drained and water controlled, the dried shrimp skins are dried with hot air at a temperature of 60-70° C., so that the dried shrimp skins have a water content of 50-55 wt %; if dried shrimp skins are used as materials, This process can be eliminated.

[0032] (2) seasoning: in order to improve food mouthfeel, adopt adding seasoning to prepare, shrimp skin is soaked in seasoning liquid for 60 minutes, drains after taking out, makes shrimp skin meat increase local flavor.

[0033] The proportions of seasonings are as follows: Shaojiu 45-55ml, white soy sauce 90-110ml, sugar 35-45g, pepper 0.4-0.6g, Chinese prickly ash 1.5-2.5g, monosodium glutamate 2.5-3.5g, white pepper 1.5-2.5g .

[0034] (3) For the first drying, hot air drying or microwave drying is used. The purpose is to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com