Flat flow countercurrent composite desulfurization absorption tower

A desulfurization absorption tower and countercurrent technology, which is applied in the field of advection and countercurrent composite desulfurization absorption towers, can solve the problems of fast flue gas flow rate, high outlet flue gas temperature, and reactive power consumption, so as to ensure desulfurization efficiency, improve desulfurization efficiency, and save operation The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiment of the present invention will be described in detail below in conjunction with accompanying drawing:

[0019] In the following definitions of direction, all are in accordance with figure 1 The direction observed in is defined.

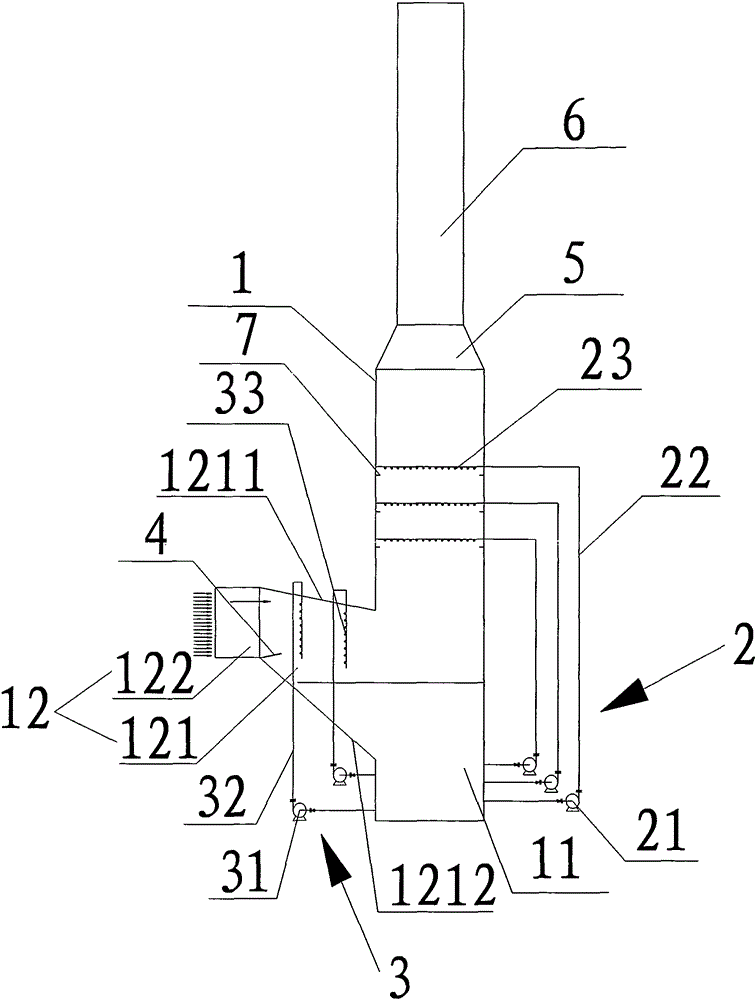

[0020] like figure 1 The advection-counterflow composite desulfurization absorption tower mainly includes a tower body 1 , a first spray assembly 2 and a second spray assembly 3 .

[0021] Among them, the tower body 1 is divided into lower part, middle part and upper part from bottom to top, and its lower part is provided with a slurry holding tank 11 for storing and storing spray liquid; its middle part or / and the side wall of the lower part is provided with an air duct 12, used to introduce the flue gas containing sulfur dioxide into the tower body 1; The contact of the liquid phase is beneficial to reduce the flow velocity of the flue gas, and play the role of stabilizing the flow, cooling down and improving the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com