Novel detection reactor

A reactor, a new type of technology, applied in the direction of chemical instruments and methods, chemical/physical processes, etc., can solve the problems of small fluidized bed reactions such as impracticality, high cost, and complex structure, so as to increase the contact area of gas and solid, The effect of low cost and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

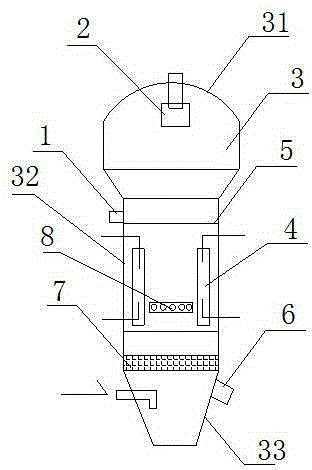

[0014] see figure 1 , a new detection reactor, the reactor includes a reactor body 3, a cyclone separator 2 is arranged on the reactor body 3, a heat exchange assembly and an internal component 5 are arranged in the middle of the reactor body, the The bottom of the reactor body is provided with a discharge port 6 and a gas distribution device. The heat exchange assembly includes a tubular heat exchanger 4 and a box heat exchanger 8, and the tubular heat exchanger is symmetrically distributed on the reactor body. The box-type heat exchanger is set as the bottom in the middle of the reactor body, and the gas distribution device 7 is set as one of side flow distribution plate, sieve plate type distribution plate or packing type distribution plate. The side flow type distribution plate, the sieve plate type distribution plate or the packing type distribution plate described in this technical solution can make the gas distribution more uniform, and will not cause channeling, no lea...

Embodiment 2

[0016] see figure 1 , as an improvement of the present invention, the reactor body includes a top cover 31, a cylinder body 32 and a bottom cover 33, the cylinder body 32 is set in a cylindrical shape, the top cover 31 is set in an oval shape, the The bottom cover 33 is configured in a conical shape. In this technical solution, the upper part of the body is a gas-solid separation space, and its diameter is often larger than that of the cylinder, and a gas-solid separation device is installed inside. The middle part of the body is the basic space for fluidization and reaction, and the bottom part of the body is the gas The distribution space is equipped with gas distribution devices. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0018] see figure 1 , as an improvement of the present invention, the internal component 5 is set as a louvered baffle. When the flow rate is low, louver-type baffles can be used to improve the contact between the gas-solid two-phase in the bed, reduce axial back-mixing, improve fluidization quality and high reaction efficiency, and reduce the height of the fluidized bed. The carry-out of particles is reduced, and the rest of the structure and advantages are exactly the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com