Intelligent sensing grinding robot system with anti-explosion function

A robot system and intelligent perception technology, applied to the parts of grinding machine tools, machine tools suitable for grinding workpiece edges, grinding workpiece supports, etc., to achieve the effects of shortening time, improving surface processing quality, and reducing the demand for grinding workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

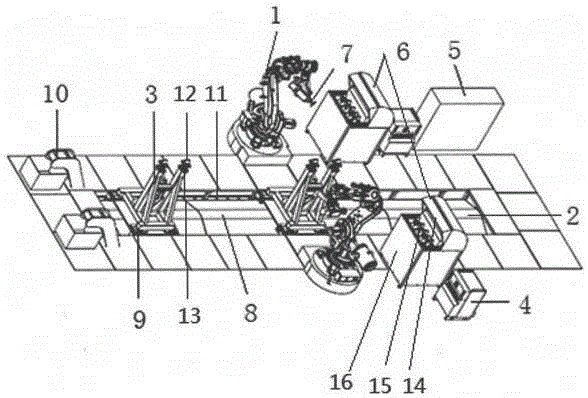

[0018] For further elaborating the technical means and the effect thereof that the present invention takes, below in conjunction with preferred embodiment of the present invention and its Attached picture Describe in detail.

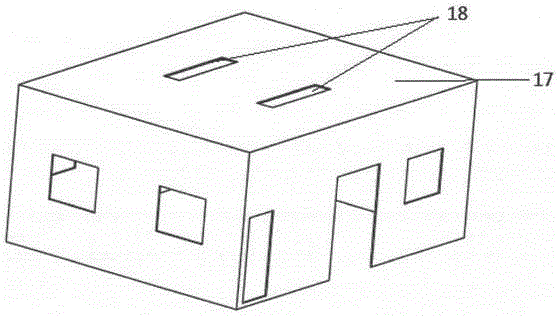

[0019] see figure 1 , the intelligent sensing grinding robot system with explosion-proof function provided by the present invention includes: industrial grinding robot 1, 3D vision system, force / position hybrid control system, explosion-proof device, transmission system 2, vibration reduction tooling frame 3, industrial grinding Robot control cabinet 4, main electric control cabinet 5, dust-proof automatic tool changer 6; the arm of the industrial grinding robot 1 is provided with an electric spindle 7 with automatic tool change function; the transmission system consists of a slide table, a slide block 9. The cover plate 8 is composed of the slide table embedded in the ground groove, and the slide block 9 and the cover plate 8 are arranged on the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com