3D projection type photocuring 3D printing machine

A 3D printer and stereoscopic projection technology, applied in the direction of additive processing, etc., can solve problems such as time-consuming and long printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] First of all, it must be pointed out that this embodiment is only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

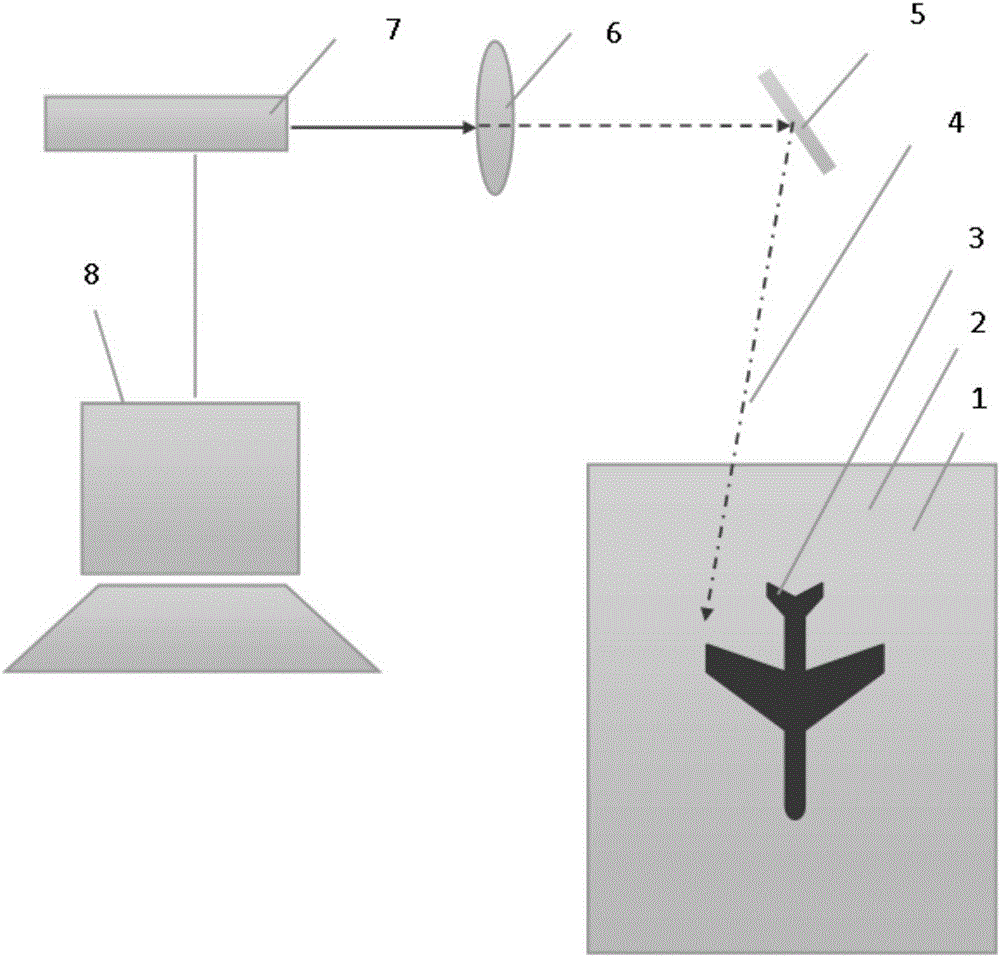

[0022] The overall device such as figure 1 As shown, the Z-axis focusing vibrating mirror 6 adopts a voice coil motor during assembly, and the reciprocating vibration frequency is greater than 20 Hz; the resin tank 1 is filled with transparent photosensitive resin 2 . The present embodiment adopts the laser device 7 that emits the green laser of 532nm, the photosensitive resin material selects SOMOS material, and the threshold is 50mw / cm 2 . Both the Z-axis focusing galvanometer 6 and the XY scanning galvanometer 5 are coated. Before printing starts, use 3D software on the computer to process the STL 3D model (with a diameter of 100mm and a height of 200mm) in layers along the Z-axis direction, with a layer thickness of 0.1mm, and obtain a series of The x,y scan of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com