A kind of plastic base material for making security documents and preparation method thereof

A technology for plastic substrates and security documents, applied in the field of plastic substrates, can solve the problems of poor tolerance, difficult to realize windows, insufficient anti-counterfeiting ability, etc., and achieve the effect of high anti-counterfeiting level and effective anti-counterfeiting technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

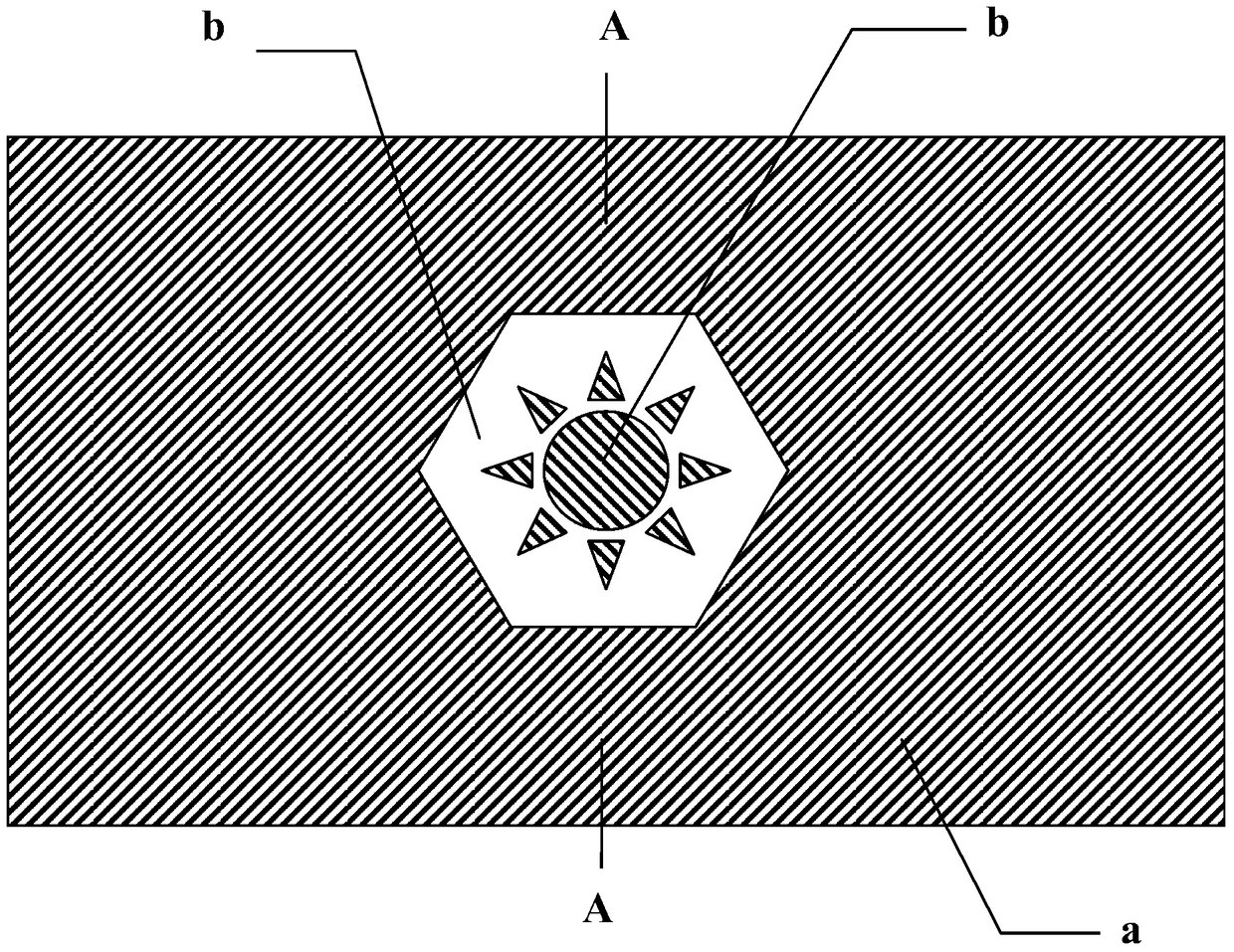

Image

Examples

Embodiment 1

[0050] Step 1, 5% (mass percentage, the same below) of titanium dioxide (purchased from DuPont, model R104), 50% of calcium carbonate (purchased from Guangzhou Jialiang, 2000 mesh), 10% of maleic anhydride graft poly Propylene (purchased from Nanjing Sutai, ST-5), 35% terpolymerized polypropylene (copolymerized PP, terpolymer of propylene, ethylene, 1-butene, melting point 137 ° C, purchased from Basel Corporation, Model Adsyl3C30FHP) is uniformly mixed by a high-speed kneader, then granulated by twin-screw extrusion, melt extrusion casting, longitudinal stretching, and corona to make a film a with a thickness of 35 microns.

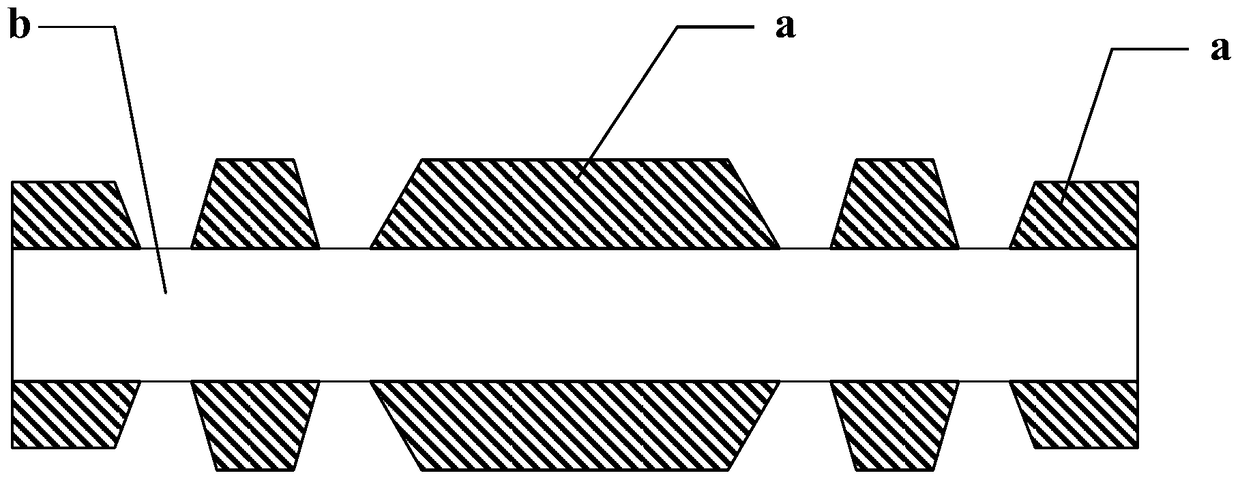

[0051] Step 2, the film a in step 1 and the purchased 48 micron thick double-sided heat-sealed polypropylene film b (BOPP heat-sealed film, purchased from Shanghai Huyuan Packaging Factory with a melting point of about 173°C) at 140±5°C Heat-compression compounding, heat-press film a on the upper and lower sides of film b respectively, and make a composi...

Embodiment 2

[0054] Step 1, the raw materials used are the same as in Example 1, and the formula is: titanium dioxide 5% (mass percentage, the same below), calcium carbonate 50%, maleic anhydride grafted polypropylene 15%, terpolymerized polypropylene 30%, After being uniformly mixed by a high-speed kneader, a film a with a thickness of 35 microns is made by twin-screw extrusion granulation, melt extrusion casting, longitudinal stretching, and corona.

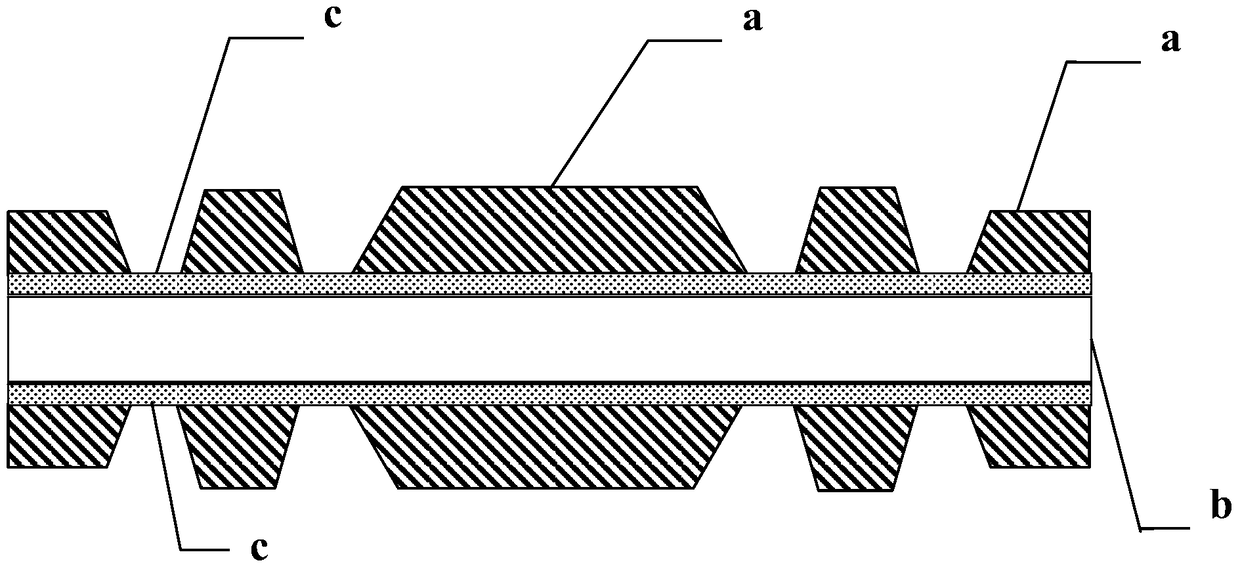

[0055] Step 2, paste the film a in step 1 on the purchased 35 micron thick two-way stretch film with an adhesive (solvent-free reactive adhesive, purchased from Shanghai Kangda Chemical New Material Co., Ltd., model WD8158A / B). Stretch the upper and lower sides of polyethylene terephthalate (BOPET, purchased from DuPont) film b to make a composite film a-c-b-c-a with a thickness of 111 microns, where c is the adhesive layer, and the two adhesive layers c are both 3 microns thick,

[0056] In step 3, the composite film a-c-b-c-a in step 2 i...

Embodiment 3

[0058] Step 1, 4% (mass percentage, the same below) of titanium dioxide (purchased from DuPont, model R104), 96% of copolyamide (melting point 125 ° C, purchased from Shanghai Tianyang Hot Melt Adhesive Co., Ltd., model JCC- 6300), after being uniformly mixed by a high-speed kneader, extruding and granulating by twin-screw, melt extrusion and spinning to make 45 micron thick non-woven fabric a,

[0059] Step 2, pass through the adhesive (the adhesive requires a peel strength of 2N / 15mm, and it only needs to not lose its bond strength when exposed to water. For example, a solvent-free reactive adhesive can be used, purchased from Shanghai Kangda Chemical New Material Co., Ltd. , model WD8158A / B) paste the non-woven fabric a obtained in step 1 on the upper and lower surfaces of the purchased BOPET film (purchased from DuPont, thickness 28 microns) to make a 124 micron thick composite film a-c-b-c-a, where c is glue Adhesive layer, both adhesive layers c are 3 microns thick,

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com