Separated reaction flywheel body

A reaction flywheel, split-type technology, applied in the field of spacecraft control, can solve the problems of unobtained moment of inertia/mass ratio, small radial size, and increased mass of the overall structure of the flywheel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in more detail hereinafter with reference to the accompanying drawings showing embodiments of the invention. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein.

[0016] Now, the present invention will be further explained by describing preferred specific embodiments according to the present invention in detail.

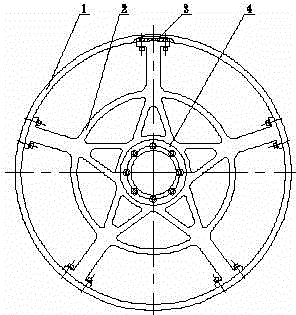

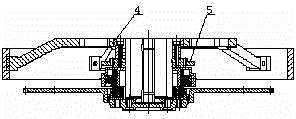

[0017] Such as figure 1 with figure 2 As shown, it is the split wheel body of this embodiment. The rim 1 is made of stainless steel and is an annular structure. Several screw holes are evenly distributed in the radial direction to connect coaxially with the hub 4. Shallow holes are provided on both ends of the wheel. For de-weighting and dynamic balancing. The spoke 2 is a disc-shaped spoke structure, and adopts an odd number of ribs and a pentagonal structure to ensure good mechanical properties. There is a machining allowance for the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com