Method for preparing activated carbon through walnut shells and application of activated carbon to degradation of substituted ureas herbicides isoproturon through specific adsorption-catalysis

A technology for preparing activated carbon and walnut shells, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc. The effect of strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] h 3 PO 4 Preparation of impregnating material: Accurately weigh 5g of pretreated walnut shells of 40-120 mesh and place them in a beaker, and set the impregnating ratio according to the experiment (H 3 PO 4 The ratio of walnut shell mass) is 1:1 by adding 25mL of H 3 PO 4 solution, fully stirred and then sealed, dipped in an oven at 90°C for 15 hours, removed the seal, dried in an oven at 120°C for 12 hours, and stirred regularly to loosen, after drying, H 3 PO 4 Dipping material.

[0036] h 3 PO 4The impregnated material was then carbonized at 250°C for 60 minutes and activated at 500°C for 60 minutes. 2 Protect and cool down to room temperature to obtain the activated material. The activated material is acid-washed and washed with water, and dried to finally obtain the target product A.

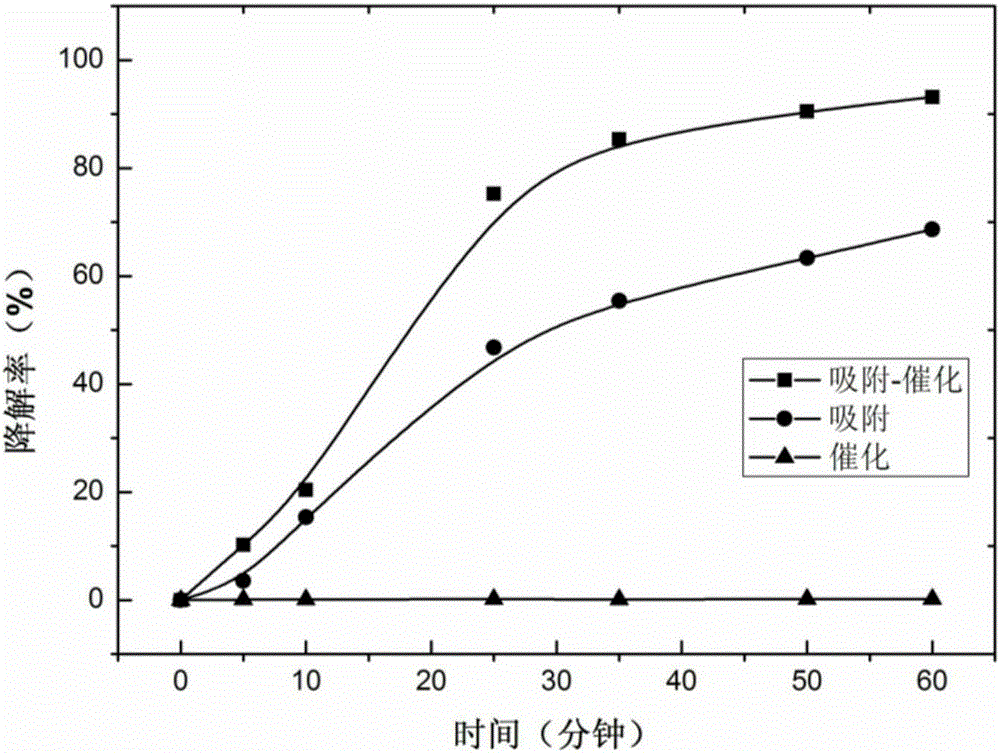

[0037] Add 10 mg of target product A to 3 mL of isoproturon aqueous solution with a concentration of 100 μmol / L, and perform adsorption treatment and adsorption-catalysis s...

Embodiment 2

[0042] in H 3 PO 4 During the preparation of the impregnating material, according to the impregnating ratio of 2:1 (H 3 PO 4 Ratio to walnut shell mass) Add 25mL of H 3 PO 4 Solution, other steps and conditions are all the same as in Example 1, and target product B is obtained.

[0043] Using the target product B, according to the steps and conditions of Example 1, the adsorption-catalysis synergy treatment was carried out for 60 minutes, and the performance of the activated carbon material was evaluated by the above formula, reaching 83.14%.

Embodiment 3

[0045] in H 3 PO 4 During the preparation of the impregnating material, according to the impregnating ratio of 4:1 (H 3 PO 4 Ratio to walnut shell mass) Add 25mL of H 3 PO 4 Solution, other steps and conditions are all the same as in Example 1, and target product C is obtained.

[0046] Using the target product C, according to the steps and conditions of Example 1, the adsorption-catalysis synergy treatment was carried out for 60 minutes, and the performance of the activated carbon material was evaluated by the above formula, reaching 86.76%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com