Composite polymeric flocculant and preparation method thereof

A composite polymer and flocculant technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of limited flocculation ability, achieve high Zeta potential positive charge, overcome poor flocculation effect, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

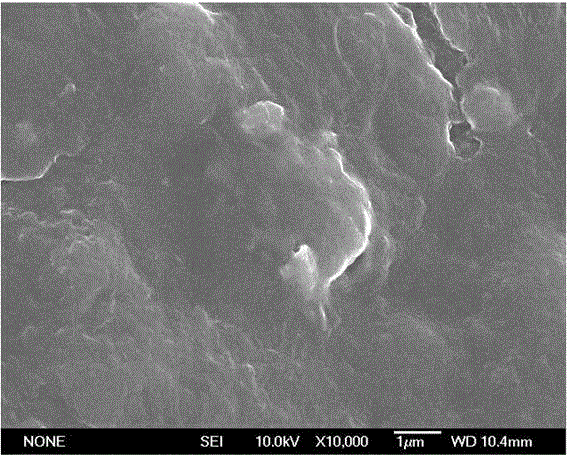

Image

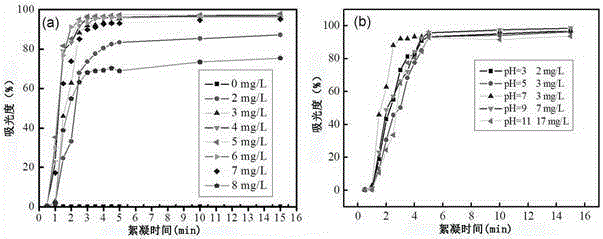

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of cationic dextran cross-linked chitosan flocculant with higher degree of etherification:

[0031] (1) Dissolve 3.24g of dextran evenly in 10mL of distilled water containing 1.5g of sodium hydroxide, and add 0.02mol of cationic etherifying agent dropwise into the dextran solution at 60°C (dropping for about 20min ) Then the reaction was carried out for 12h. The cationic dextran solution obtained after the reaction was added dropwise into 90% ethanol solution, and the vacuum distillation device was used for suction filtration to obtain the precipitated white cationic dextran solid. Then use ethanol solution to wash 2-3 times.

[0032] (2) Add the cationic dextran solution obtained after the reaction dropwise into 90% ethanol solution, and perform suction filtration with a vacuum distillation device to obtain the precipitated white cationic dextran solid. Then use ethanol solution to wash 2-3 times.

[0033] (3) Weigh 0.7 g of the cationi...

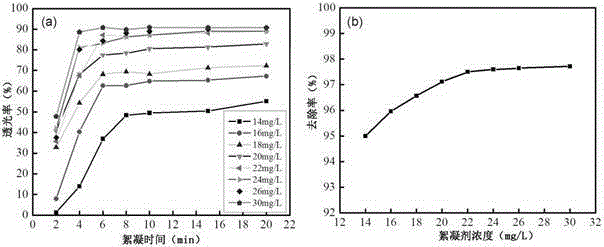

Embodiment 2

[0037] Embodiment 2: Preparation of cationic dextran cross-linked chitosan flocculant with moderate degree of etherification:

[0038] The specific steps are as follows:

[0039] (1) Dissolve 3.24g of dextran evenly in 10mL of distilled water containing 1.5g of sodium hydroxide, and add 0.015mol of cationic etherifying agent dropwise into the dextran solution at 60°C (dropping for about 20min ) Then the reaction was carried out for 8h. The cationic dextran solution obtained after the reaction was added dropwise into 90% ethanol solution, and the vacuum distillation device was used for suction filtration to obtain the precipitated white cationic dextran solid. Then use ethanol solution to wash 2-3 times.

[0040] (2) Add the cationic dextran solution obtained after the reaction dropwise into 90% ethanol solution, and perform suction filtration with a vacuum distillation device to obtain the precipitated white cationic dextran solid. Then use ethanol solution to wash 2-3 time...

Embodiment 3

[0044] Example 3: Preparation of cationic dextran cross-linked chitosan flocculant with lower degree of etherification

[0045] The specific steps are implemented as follows:

[0046] (1) Dissolve 3.24g of dextran evenly in 10mL of distilled water containing 1.5g of sodium hydroxide, and add 0.005mol of cationic etherifying agent dropwise to the dextran solution at 60°C (dropping for about 20min ) Then the reaction was carried out for 8h. The cationic dextran solution obtained after the reaction was added dropwise into 90% ethanol solution, and the vacuum distillation device was used for suction filtration to obtain the precipitated white cationic dextran solid. Then use ethanol solution to wash 2-3 times.

[0047] (2) Add the cationic dextran solution obtained after the reaction dropwise into 90% ethanol solution, and perform suction filtration with a vacuum distillation device to obtain the precipitated white cationic dextran solid. Then use ethanol solution to wash 2-3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com