Low-creep azorite indecomposable overflow brick and preparation method thereof

An overflow brick and zircon technology, which is applied in the field of refractory materials, can solve the problems of easy cracking of large overflow bricks, slow heating and cooling, etc., and achieve the effects of convenient large-scale industrial production, small addition amount and high bulk density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

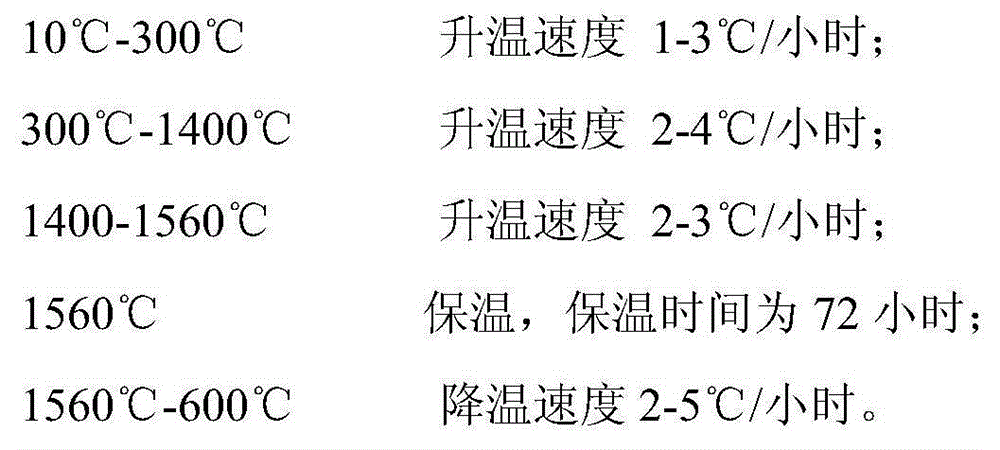

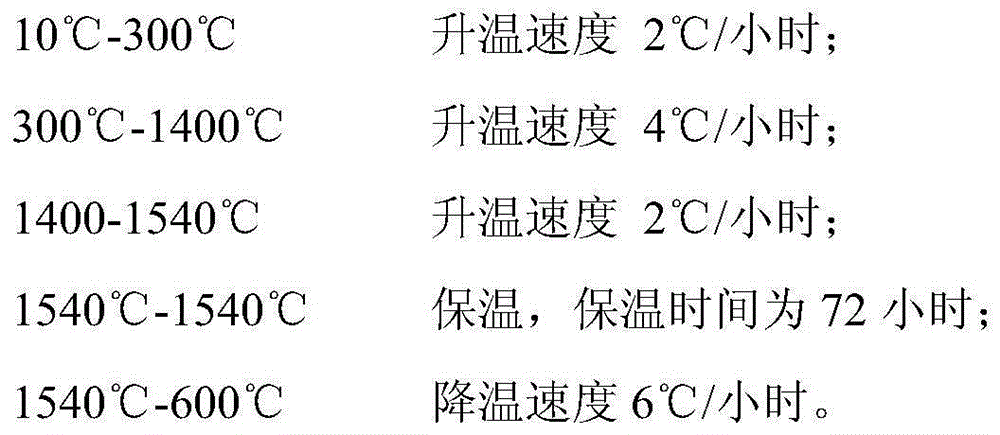

Method used

Image

Examples

Embodiment 1

[0058] The raw material zircon powder 1# includes the following components in mass percentage:

[0059] Al 2 o 3 0.39%, Fe 2 o 3 0.05%, CaO 0.02%, MgO 0.00%, K 2 O is 0.01%, Na 2 O is 0.01%, SiO 2 32.9%, TiO 2 0.12%, P 2 o 5 0.15%, ZrO 2 was 66.1%.

[0060] The raw material ilmenite powder 1# median diameter ≤ 3μm, including the following components in mass percentage: TiO 2 is 49.5wt%, FeO is 36.5wt%, Fe 2 o 3 9.8%, Al 2 o 3 1.07%, SiO 2 0.82% for CaO, 0.62% for CaO, and 0.75% for MgO.

[0061] The above-mentioned raw materials are all commercially available commodities.

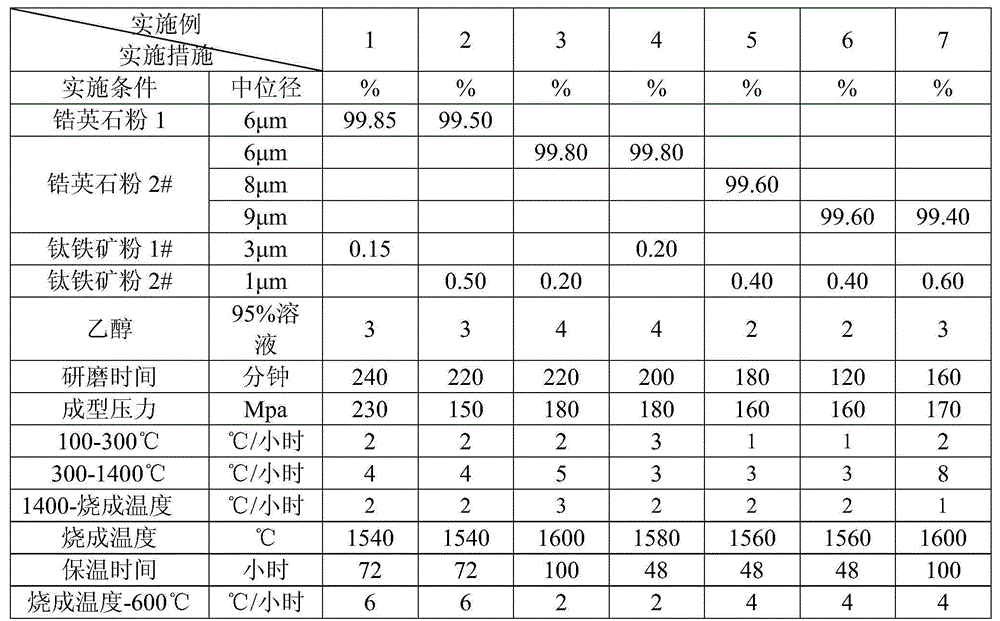

[0062] The content of each raw material in this embodiment is shown in Table 1.

[0063] A method for preparing an overflow brick with low creep and zircon that does not decompose, comprising the following steps:

[0064] 1) Prepare batch materials according to zircon powder and ilmenite powder;

[0065] 2) The batch material is wet-grinded and spray-granulated to form granulated powder,...

Embodiment 2

[0072] The raw material zircon powder 1# used is the same as that in Example 1; the median diameter of the raw material ilmenite powder 2# used is ≤1 μm, and the chemical composition is TiO 2 is 51.8wt%, FeO is 38.9wt%, Fe 2 o 3 4.0%, Al 2 o 3 1.42%, SiO 2 0.92% for CaO, 0.06% for CaO, and 0.17% for MgO.

[0073] The preparation method of the zircon sintered product described in Example 2 is the same as that of Example 1, and the mass ratio of the raw materials used and the parameters in the preparation process are shown in Table 1.

Embodiment 3-12

[0074] The raw material zircon powder 2# used in embodiment 3-12 comprises the following components in mass percentage:

[0075] Al 2 o 3 0.08%, Fe 2 o 3 0.04%, CaO 0.02%, MgO 0.00%, K 2 O is 0.01%, Na 2 O is 0.01%, SiO 2 33.1%, TiO 2 0.08%, P 2 o 5 0.11%, ZrO 2 was 66.4%.

[0076] The preparation method of zirconite sintered products described in Examples 3-12 is the same as that of Example 1, the mass ratio of raw materials used in Examples 2-7, and the parameters in the preparation process are shown in Table 1; The ratio of raw materials and the parameters in the preparation process are shown in Table 2.

[0077] The detection method in Examples 2-12 is the same as that in Example 1, and the detection data of Examples 1-7 are shown in Table 3; the detection data of Examples 8-12 are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com