Permeable crystallization type concrete waterproofing agent

A technology of concrete waterproofing agent and osmotic crystallization, applied in the field of concrete building waterproofing materials, can solve the problems of high production cost of waterproofing materials, limiting the application scope of concrete waterproofing engineering, etc. The effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with embodiment, the present invention will be further described:

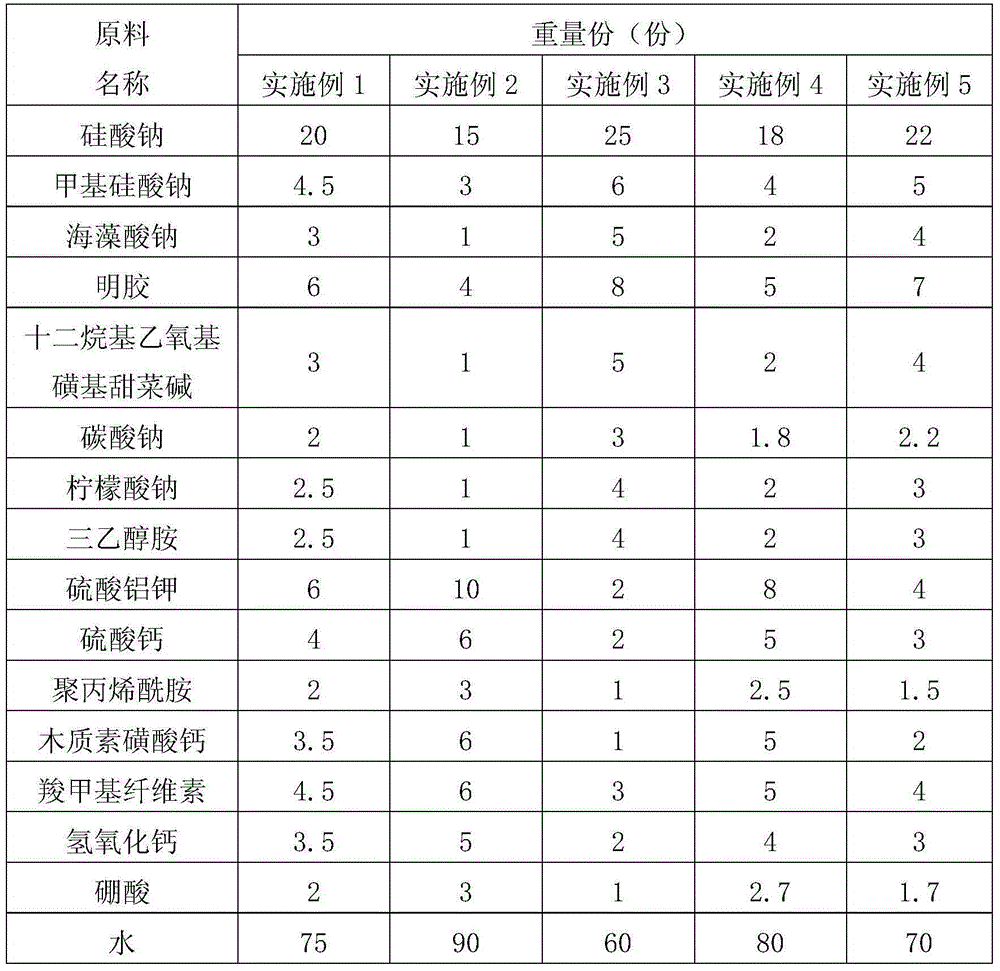

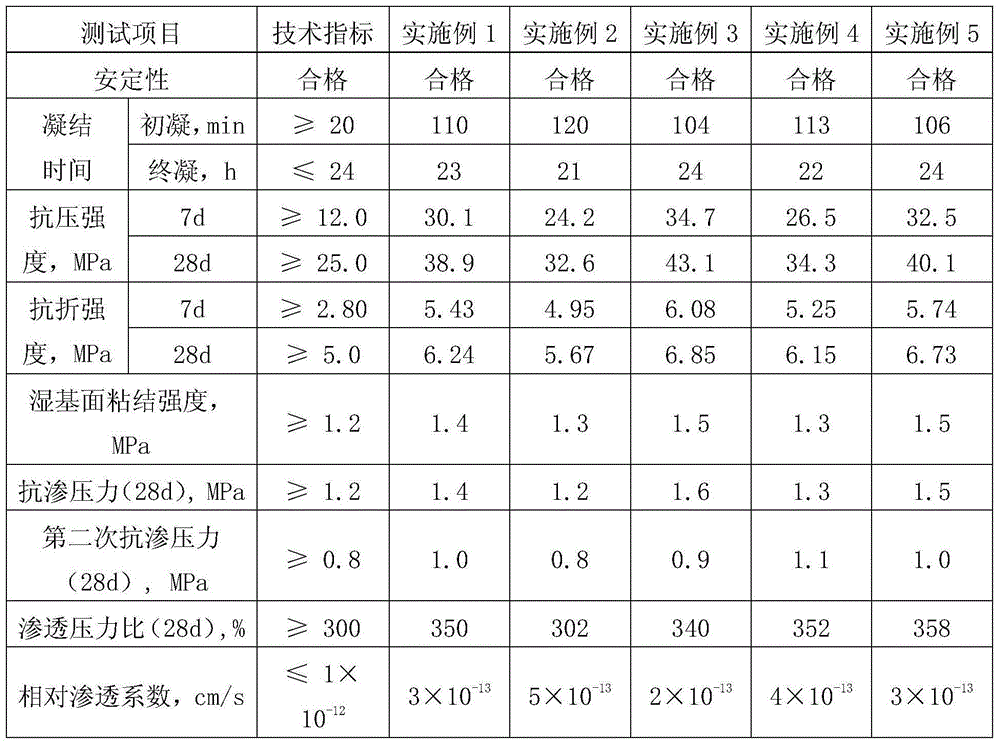

[0028] The osmotic crystalline concrete waterproofing agent of the present invention is made of the following components by weight: 15-25 parts of sodium silicate, 3-6 parts of sodium methyl silicate, 1-5 parts of sodium alginate 4-8 parts of gelatin, 1-5 parts of dodecyl ethoxy sulfobetaine, 1-3 parts of sodium carbonate, 1-4 parts of sodium citrate, 1-4 parts of triethanolamine, 2 parts of potassium aluminum sulfate ~10 parts, calcium sulfate 2~6 parts, polyacrylamide 1~3 parts, calcium lignosulfonate 1~6 parts, carboxymethyl cellulose 3~6 parts, calcium hydroxide 2~5 parts, boric acid 1~ 3 parts, 60-90 parts of water. In specific implementation, it can be directly applied to the base surface to be waterproofed by spraying or brushing, and repeated brushing to a certain thickness, and curing for 3 days or more is enough.

[0029] Table 1 shows the weight ratio of each component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com