Method for preparing biocontrol active liquid seaweed fertilizers

A seaweed fertilizer and active technology, which is applied to fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of wasting nutrients in seaweed residues and underutilizing plant nutrients, and achieve more complete fertilizer functions and biocontrol activities. Significant, high-yield effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

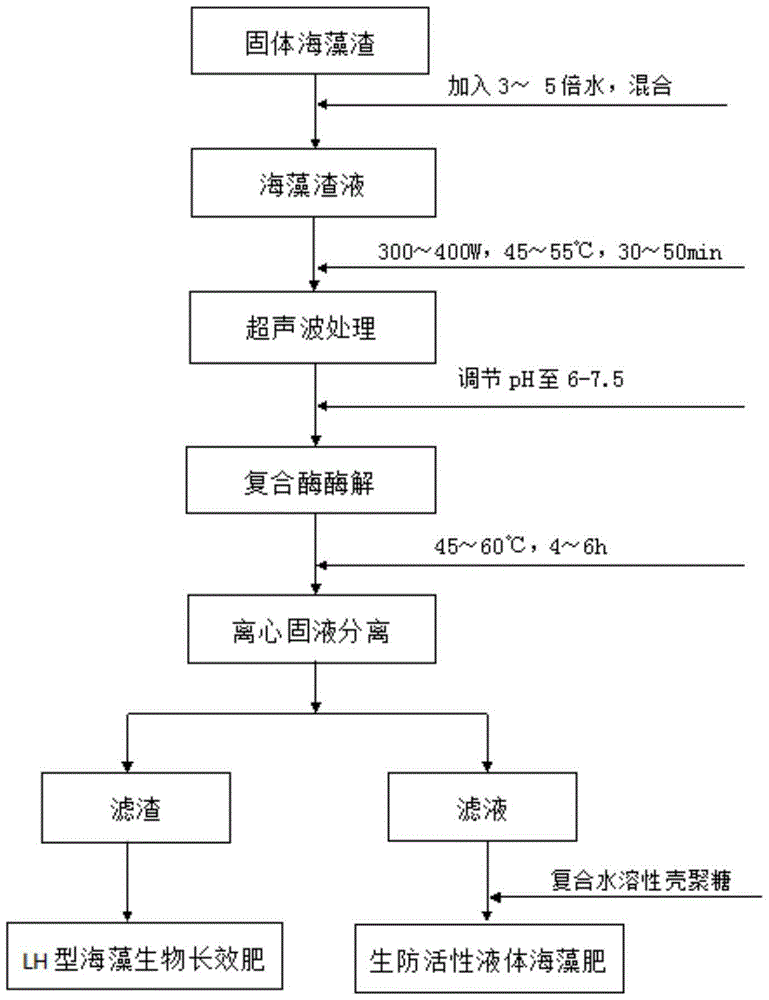

[0038] Such as figure 1 Shown, the preparation method of liquid fertilizer of the present invention specifically comprises the following steps:

[0039] Step 1. First add water to the solid seaweed residue. The amount of water added is 3 to 5 times that of the solid seaweed residue. Mix evenly to obtain the seaweed residue liquid. Put the seaweed residue liquid into the ultrasonic sample processor and set the power to 300 ~400W, temperature 45~55℃, time 30~50min, conduct ultrasonic treatment to obtain sample 1;

[0040] Step 2. Adjust the pH of sample 1 to 6-7.5, add compound enzyme for enzymolysis under stirring, the amount of compound enzyme added is 0.1-1% of the mass of sample 1, mix well and stir in a water bath for enzymolysis 4-6 hour, the reactant after enzymolysis is obtained; the above-mentioned compound enzyme comprises according to mass percentage: 20~25% cellulase, 8~12% pectinase, 7~10% chitosanase, 7~12% % hemicellulase, 21-27% papain, 14-20% neutral protease ...

Embodiment 1

[0045] The preparation method of the present embodiment liquid fertilizer specifically comprises the following steps:

[0046] Step 1. First add water to the solid seaweed residue. The amount of water added is 3 times that of the solid seaweed residue. Mix evenly to obtain the seaweed residue liquid. Put the seaweed residue liquid into the ultrasonic sample processor, set the power to 300W, and the temperature At 55°C for 30 minutes, ultrasonic treatment was performed to obtain sample 1;

[0047] Step 2. Adjust the pH of sample 1 to 7.5, and add compound enzyme for enzymolysis under stirring. The amount of compound enzyme added is 1% of the mass of sample 1. After mixing evenly, stir and enzymolyze in a water bath for 4 hours to obtain the enzymolysis The reactant; above-mentioned compound enzyme comprises according to mass percent: the cellulase of 25%, the pectinase of 8%, the chitosanase of 7%, the hemicellulase of 12%, the papain of 21%, 20% % neutral protease and 10% try...

Embodiment 2

[0051] The preparation method of the present embodiment liquid fertilizer specifically comprises the following steps:

[0052] Step 1. First add water to the solid seaweed residue. The amount of water added is 5 times that of the solid seaweed residue. Mix evenly to obtain a seaweed residue liquid. Put the seaweed residue liquid into an ultrasonic sample processor, set the power to 400W, and set the temperature At 45°C for 50 minutes, ultrasonic treatment was performed to obtain sample 1;

[0053] Step 2. Adjust the pH of sample 1 to 6, and add compound enzyme for enzymolysis under stirring. The amount of compound enzyme added is 0.1% of the mass of sample 1. After mixing evenly, stir and enzymolyze in a water bath for 6 hours to obtain the enzymolysis The reactant; above-mentioned compound enzyme comprises according to mass percentage: the cellulase of 20%, the pectinase of 12%, the chitosanase of 10%, the hemicellulase of 7%, the papain of 27%, 14% % neutral protease and 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com