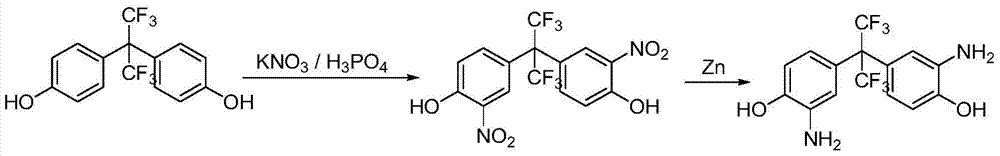

Preparation method of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane

A technology of hydroxyphenyl and hexafluoropropane, which is applied in the field of preparation of monomer 2,2-dihexafluoropropane, can solve the problems of expensive palladium carbon, potential safety hazards, and high cost, and achieve low production equipment requirements and high repeatability Good, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 3.36 kilograms of 2,2-bis(4-hydroxyphenyl) hexafluoropropane in the reactor, 4.04 kilograms of potassium nitrate, 12 kilograms of 80% phosphoric acid, and heat up to 85°C for reaction (molar ratio is: 2,2-bis( 4-Hydroxyphenyl)hexafluoropropane: potassium nitrate: 80% phosphoric acid = 1:4:10), after the reaction of the raw materials is complete, cool down to below 10°C, precipitate a solid, filter, wash and dry to obtain 2,2-bis( 4.22 kg of 3-nitro-4-hydroxyphenyl) hexafluoropropane, yellow solid, yield 98.9%.

Embodiment 2

[0023] Add 3.36 kilograms of 2,2-bis(4-hydroxyphenyl) hexafluoropropane in the reactor, 3.54 kilograms of potassium nitrate, 9.3 kilograms of 80% phosphoric acid, and heat up to 80°C for reaction (the molar ratio is: 2,2-bis( 4-Hydroxyphenyl)hexafluoropropane: potassium nitrate: 80% phosphoric acid = 1:3.5:8), after the reaction of raw materials is complete, cool down to below 10°C, precipitate solid, filter, wash and dry to obtain 2,2-bis( 4.1 kg of 3-nitro-4-hydroxyphenyl)hexafluoropropane, yellow solid, yield 96.3%.

Embodiment 3

[0025] Add 3.36 kilograms of 2,2-bis(4-hydroxyphenyl) hexafluoropropane, 4.55 kilograms of potassium nitrate, 13.8 kilograms of 80% phosphoric acid in the reactor, and heat up to 90°C for reaction (molar ratio is: 2,2-bis( 4-Hydroxyphenyl)hexafluoropropane: potassium nitrate: 80% phosphoric acid = 1:4.5:12), after the reaction of the raw materials is complete, cool down to below 10°C, precipitate a solid, filter, wash and dry to obtain 2,2-bis( 4.223 kg of 3-nitro-4-hydroxyphenyl)hexafluoropropane, yellow solid, yield 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com