Compaction processing method used for spray forming superhigh-intensity aluminum alloy material

An aluminum alloy material, spray forming technology, applied in the field of metal material processing, can solve the problems of structure defects, incomplete closure, flaky oxide layer defects, etc., to improve structure and performance, improve material density, and improve quality consistency Effects of Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

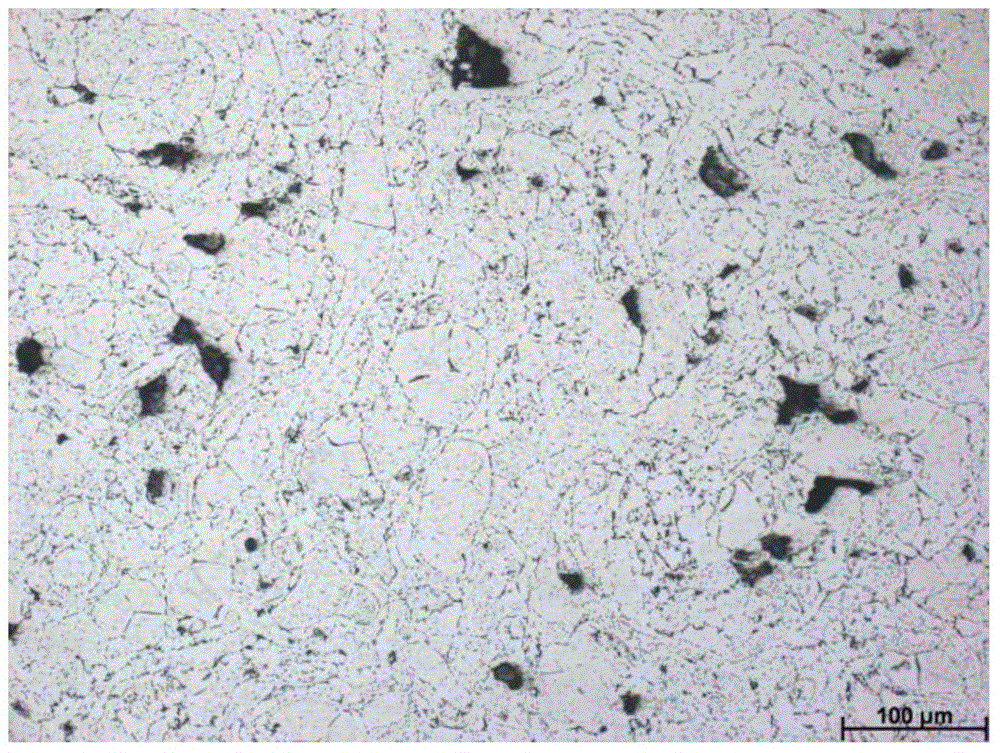

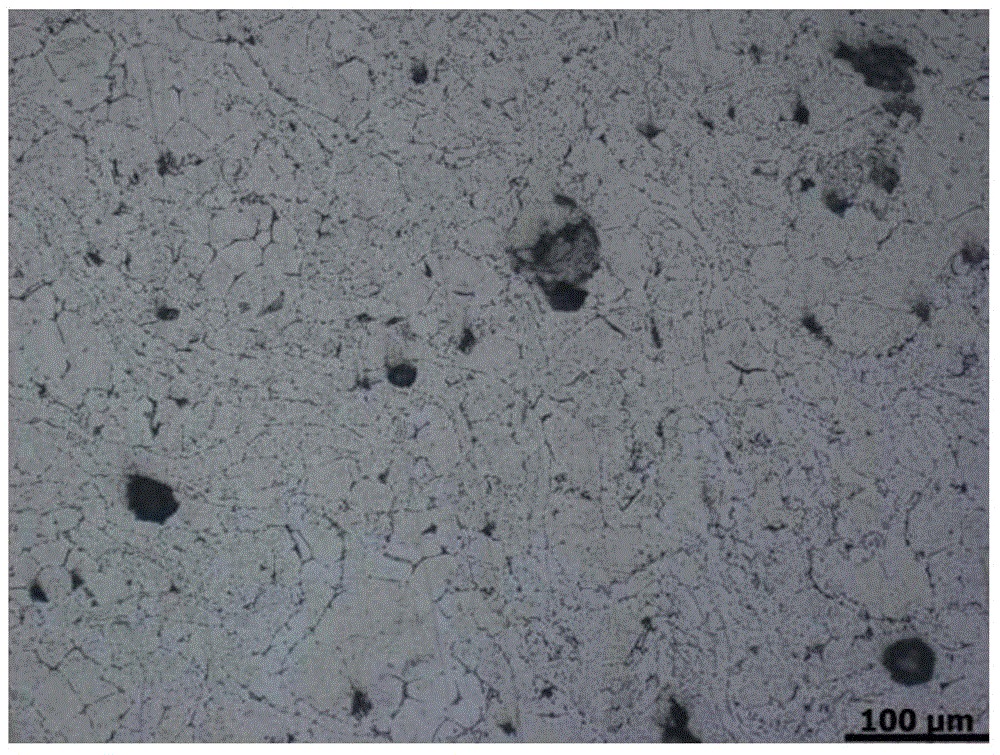

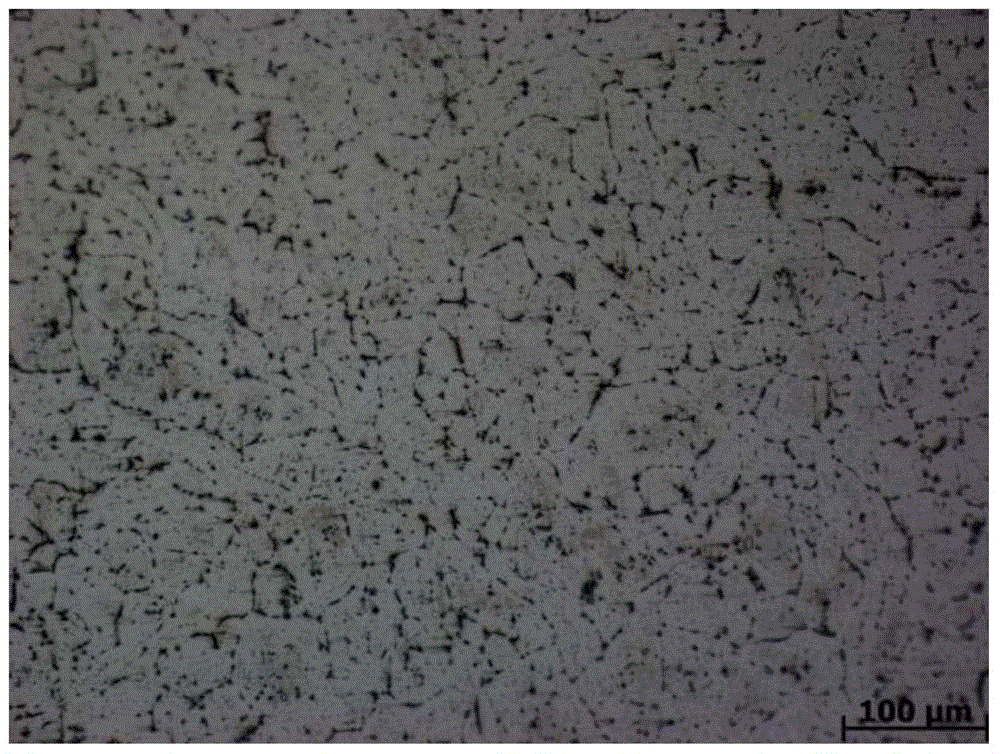

[0025] The present invention is applied to the 7A93 aluminum alloy registered in China Nonferrous Metals and Alloy Trademark, and its nominal composition range (mass fraction, %) is: Si is not higher than 0.12, Fe is not higher than 0.15, Cu1.6~2.2, Ni is not high 0.08, Mg2.0~2.6, Zn9.8~11.0, Zr0.15~0.30, balance Al and other unavoidable impurities; among them, select a typical alloy composition: 10.8% Zn, 2.5% Mg, 1.9% Cu , 0.15% Zr, the balance Al and other inevitable impurities. Machine the vehicle body from the 7A93 alloy deposition blank prepared by spray forming, such as figure 1 Shown is an optical microstructural image of a 7A93 alloy deposited blank. The 7A93 alloy prepared by spray forming was subjected to different densification treatments. The densification treatment process parameters are shown in Table 1. The densification index of the material was obtained by testing the bulk density of the densified material. After the densification treatment, 440°C×12h+472°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com