Production method of fine denier hollow staple fiber

A production method and technology of polyester staple fibers are applied in the field of melt direct spinning of fine denier hollow polyester staple fibers, which can solve the problems of yarn uniformity and physical and mechanical properties that cannot meet thin fabrics, and achieve physical and mechanical properties and appearance. Effective control of performance, good spinning performance, and the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

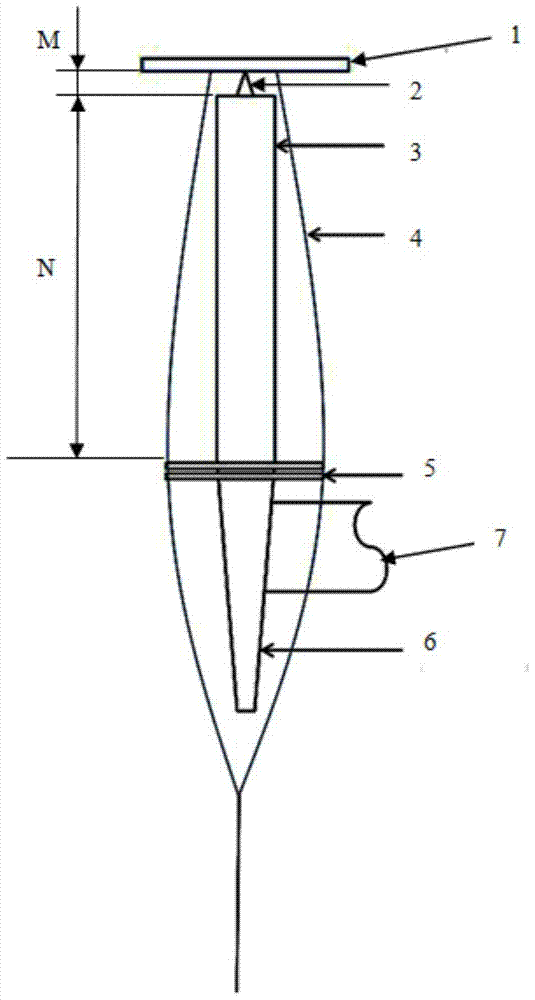

[0036] Example 1: direct spinning, target linear density 1.11dtex×38mm high-strength low-elongation cotton-type semi-dull hollow polyester staple fiber

[0037] The direct spinning process is adopted, the intrinsic viscosity of the melt is 0.670±0.015dl / g, the content of titanium dioxide as a matting agent is 0.18%wt (relative to the melt), the daily spinning output is 100 tons / day, and 32 spinning positions.

[0038] According to the parameters in Table 1, the target finished fiber outer diameter is 11.1 μm, and the target hollowness is 10.5-11.5%, which is equivalent to the diameter of a 1.33dtex fiber with a solid circular section. It is used for ring spinning and knitting yarn.

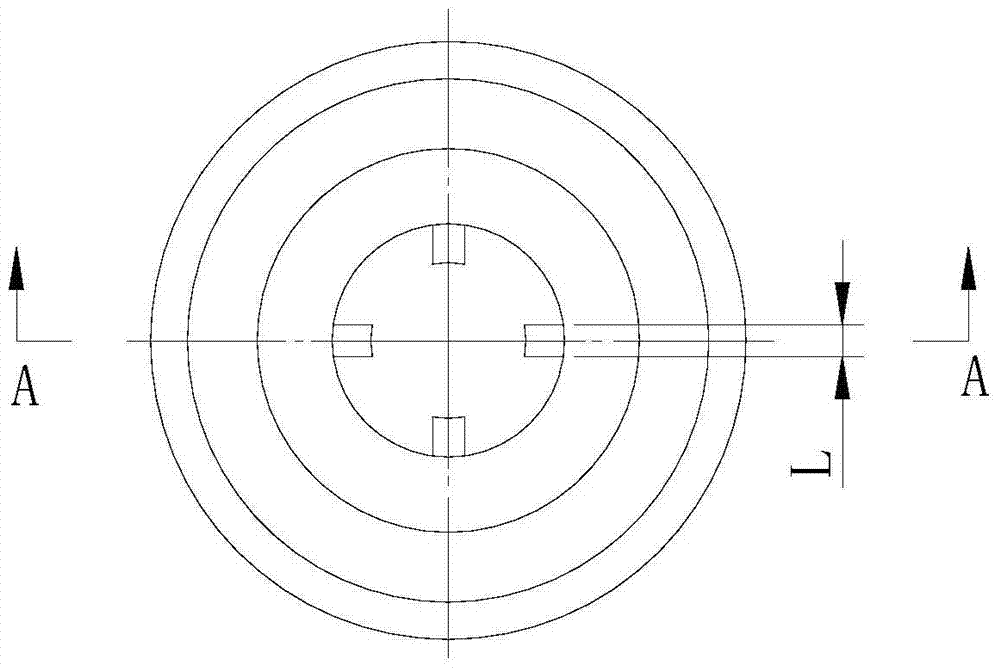

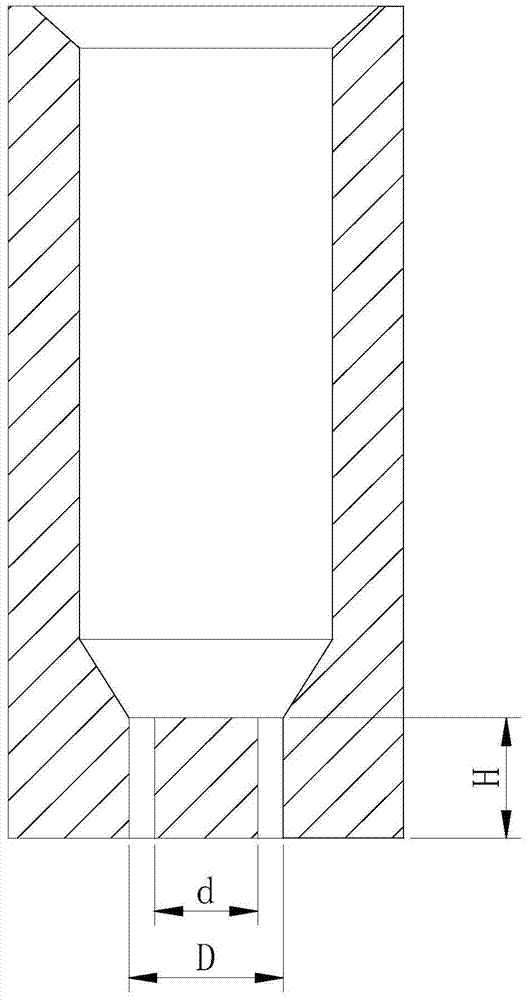

[0039] The melt temperature before entering the spinning box is 288°C, controlled by ±1°C, the diameter D of the outer arc of the spinneret microhole is 0.34mm, and the diameter d of the inner arc of the spinneret microhole is 0.18mm. The circular arc forms four symmetrical hollow fiber melt ejec...

Embodiment 2

[0042] Example 2 direct spinning, target linear density 1.33dtex × 38mm medium strength and medium elongation cotton type semi-dull hollow polyester staple fiber

[0043] The direct spinning process is adopted, the intrinsic viscosity of the melt is 0.670±0.015dl / g, the content of the matting agent titanium dioxide is 0.18%wt (relative to the melt), the daily spinning output is 100 tons / day, and 32 spinning positions.

[0044] According to the parameters in Table 1, the target finished fiber outer diameter is 12.0 μm, and the target hollowness is 13.5-15.0%, which is equivalent to the diameter of a 1.67dtex fiber with a solid circular section. It is used for ring spinning and knitting yarn.

[0045] The melt temperature before entering the spinning box is 288°C, controlled by ±1°C, the diameter D of the outer arc of the spinneret microhole is 0.34mm, and the diameter d of the inner arc of the spinneret microhole is 0.18mm. The circular arc forms four symmetrical hollow fiber ...

Embodiment 3

[0048] Example 3 direct spinning, target linear density 1.56dtex×51mm medium strength, medium elongation, medium length semi-dull hollow polyester staple fiber

[0049] The direct spinning process is adopted, the intrinsic viscosity of the melt is 0.630±0.015dl / g, the content of the matting agent titanium dioxide is 0.18%wt (relative to the melt), the daily spinning output is 100 tons / day, and 32 spinning positions.

[0050] According to the parameters in Table 1, the outer diameter of the target finished fiber is 15.0 μm, the hollowness is 16-18%, which is equivalent to the diameter of a 2.5dtex fiber with a solid circular cross-section. It is used for ring spinning and knitting yarn.

[0051] The melt temperature before entering the spinning box is 288°C, controlled by ±1°C, the diameter D of the outer arc of the spinneret microhole is 0.34mm, and the diameter d of the inner arc of the spinneret microhole is 0.18mm. The circular arc forms four symmetrical hollow fiber melt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com