Drying device for gunpowder

A technology for drying equipment and gunpowder, which is applied in drying, drying machines, lighting and heating equipment, etc., which can solve the problems of environmental protection, large space, and unsafety, and achieve space saving, high efficiency, and less space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

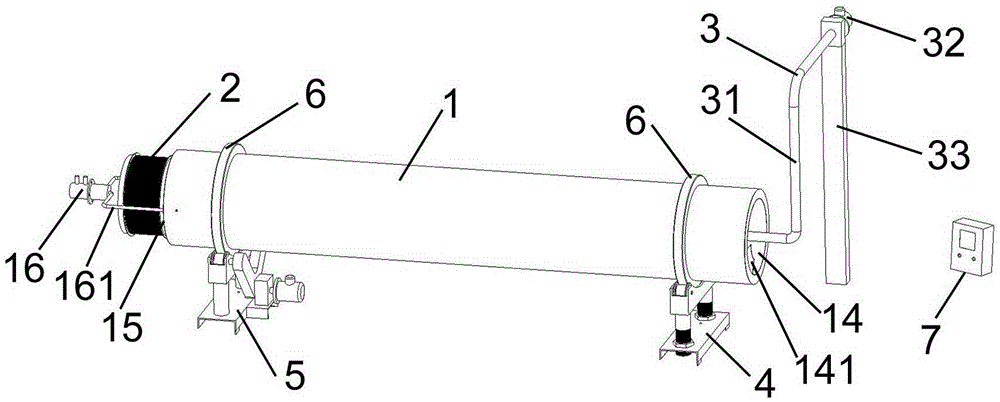

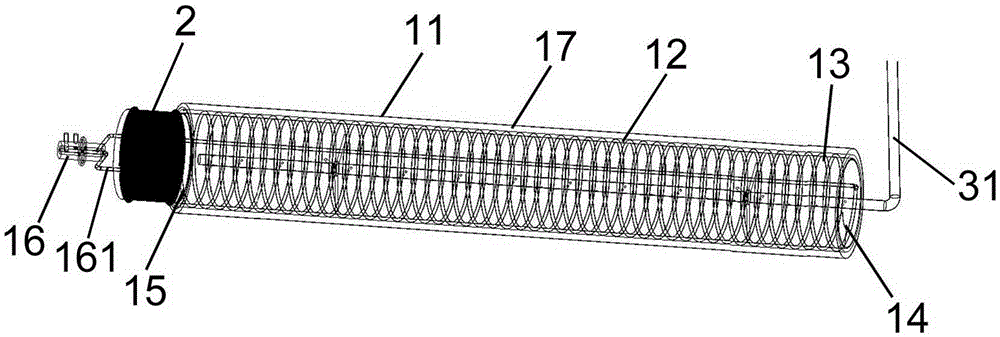

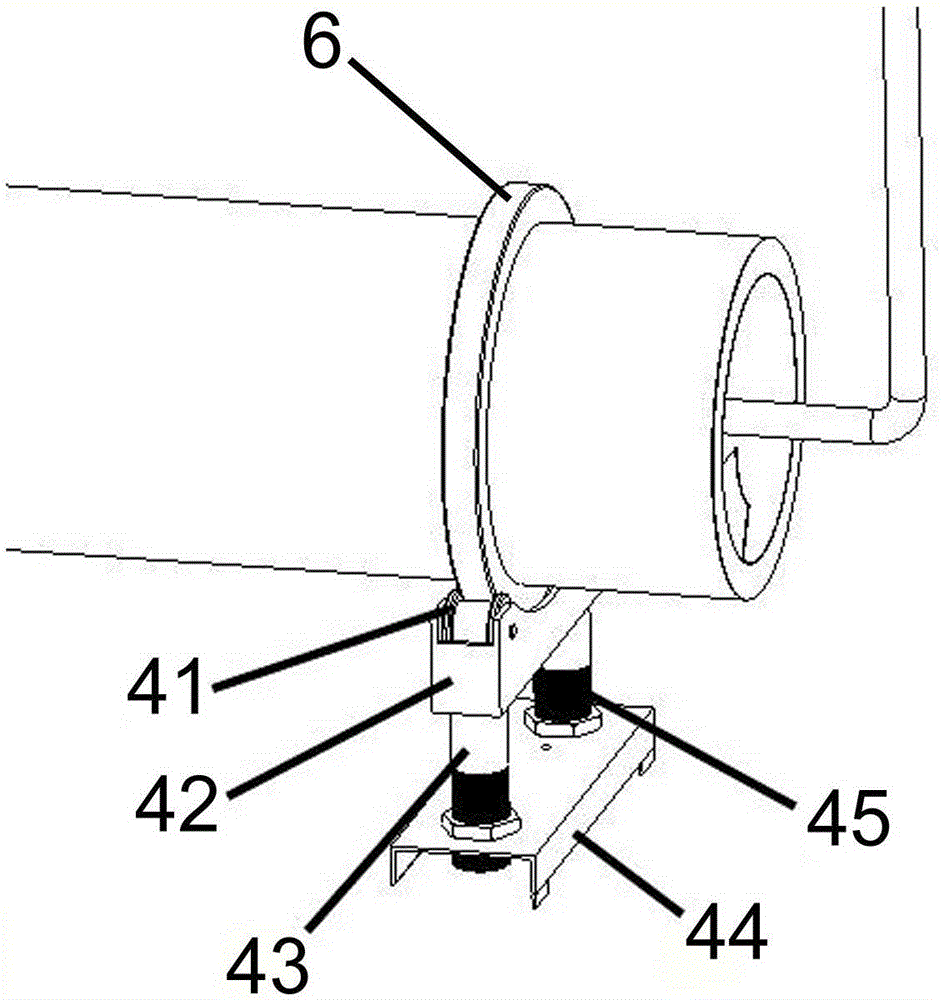

[0026] Such as figure 1 and 2 As shown, a gunpowder drying equipment includes a drying cylinder 1, a sieve 2, an air extraction device 3, a front support assembly 4, a rear support assembly 5, two guide rails 6 and an electric control box 7; the drying cylinder 1 It includes an outer cylinder 11 and an inner cylinder 12, a spiral heating tube 13 is arranged between the outer cylinder 11 and the inner cylinder 12, and a heat transfer fluid is passed through the spiral heating tube 13, and the heat transfer fluid is hot water, water vapor or heat transfer oil. The front end and the end of the drying cylinder 1 are respectively closed by the front cover 14 and the rear cover 15. The front cover 14 has a gunpowder inlet 141, and the end of the drying cylinder 1 also has a rotary valve 16, which is connected with the spiral heating tube 13. Fluid communication, there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com