A load reduction design method for intermediate bearings of aeroengines

A technology of aero-engines and bearings, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as synchronous impact, and achieve the effects of improving efficiency, simple drawing, and clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

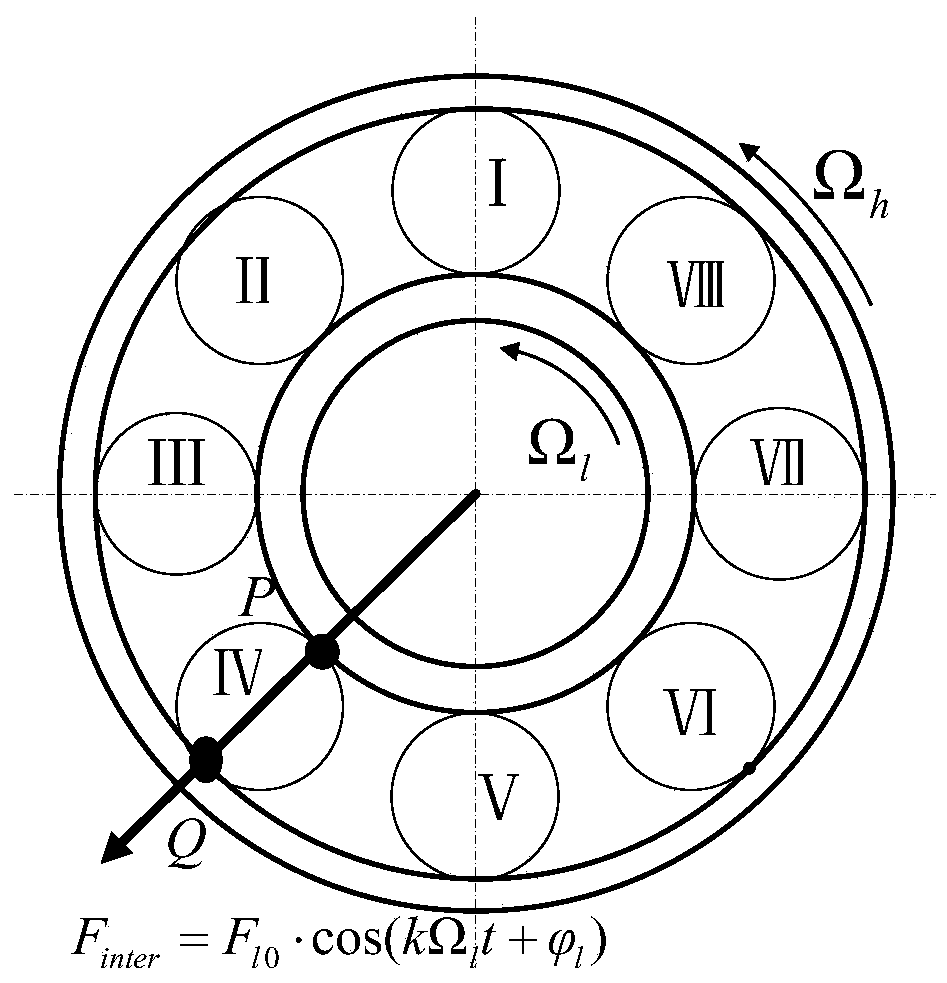

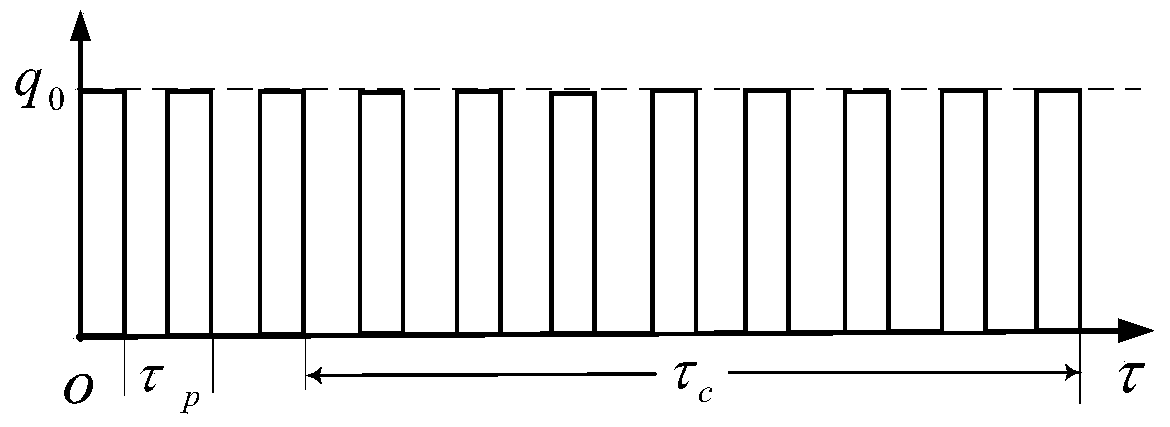

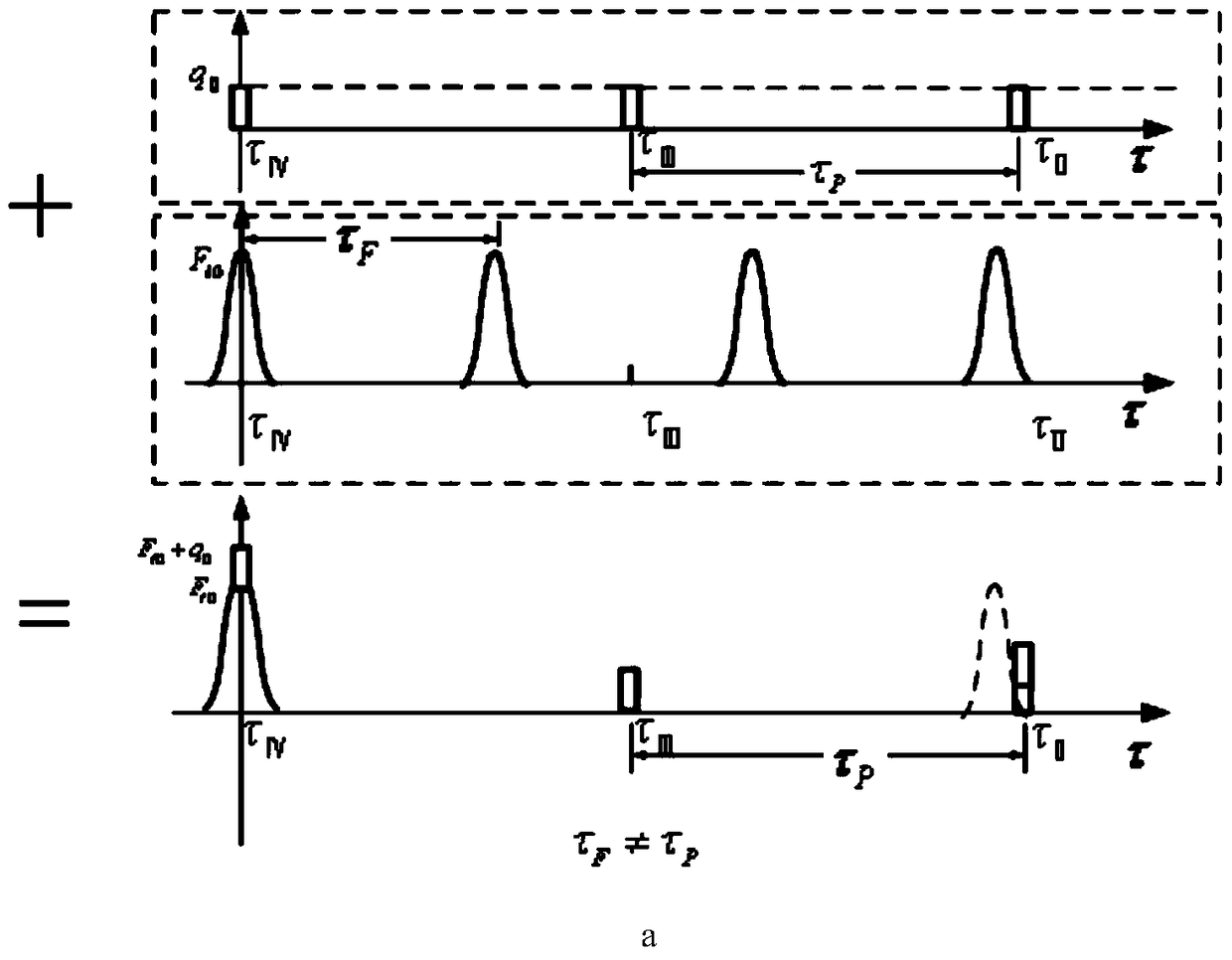

[0073] This embodiment is a method for the load reduction design of an aero-engine intermediary bearing, and the specific process is:

[0074] Step 1, determining the rotational speed ratio of the high-pressure rotor and the low-pressure rotor in the dual-rotor engine.

[0075] According to the principle of equal speed intervals, N speed operating points are selected within the working speed range of the aero-engine from idle speed to maximum speed. According to the high-pressure rotor design speed and low-pressure rotor design speed of the engine, calculate the high / low pressure rotor speed ratio under each speed conditionγ i =Ω H,i / Ω L,i =n 2,i / n 1,i ,i=(1,2...N). Among them, Ω H is the rotational angular velocity of the high voltage rotor, Ω L is the rotational angular velocity of the low pressure rotor. no 2 is the design speed of the high-pressure rotor, and its dimension is rev / min; n 1 is the design speed of the low-pressure rotor, and its dimension is rev / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com