Method for optimizing dynamic response performance of heat radiator of power device on basis of numerical iteration

A technology of numerical iteration and power devices, applied in the field of electronics, can solve the problem that there is no effective method for analyzing the dynamic response performance of radiators, and achieve the effects of optimizing dynamic response performance, increasing power cycle rate, and reducing junction temperature fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

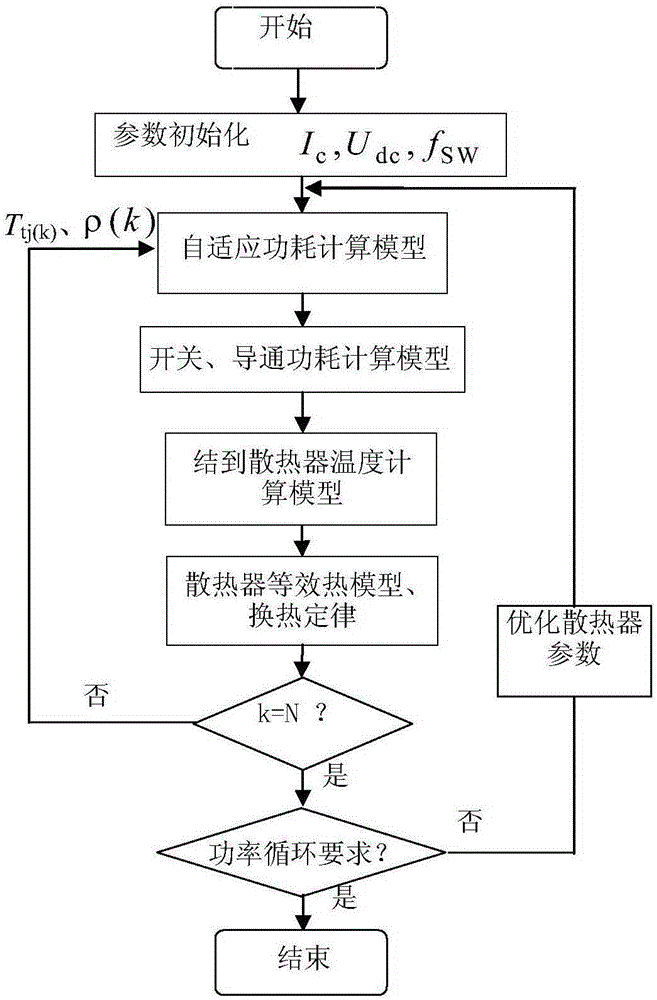

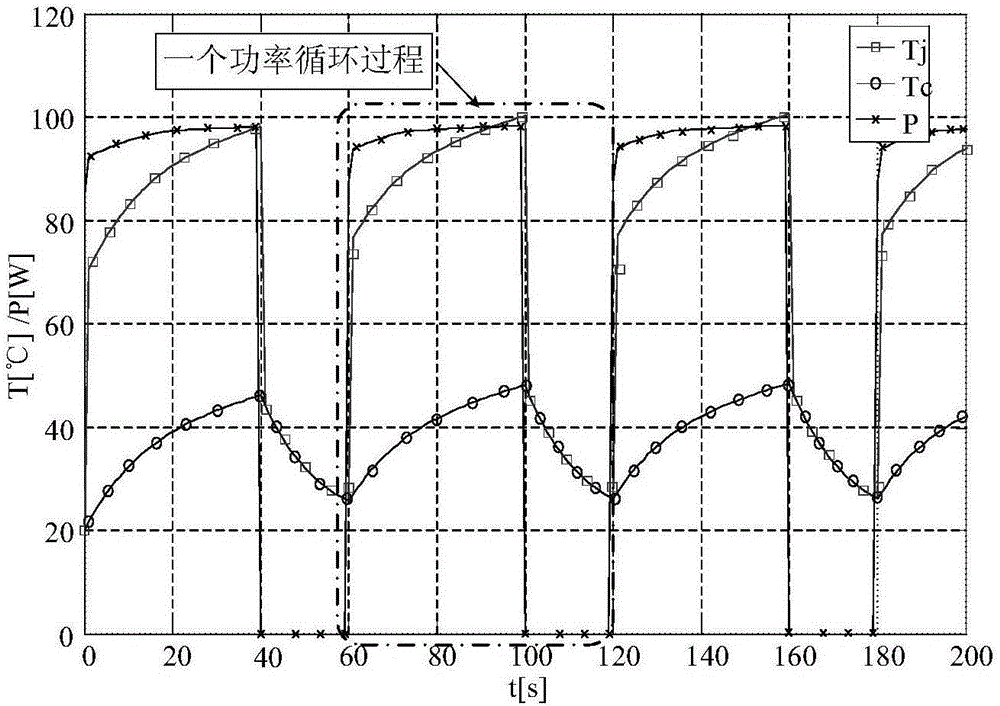

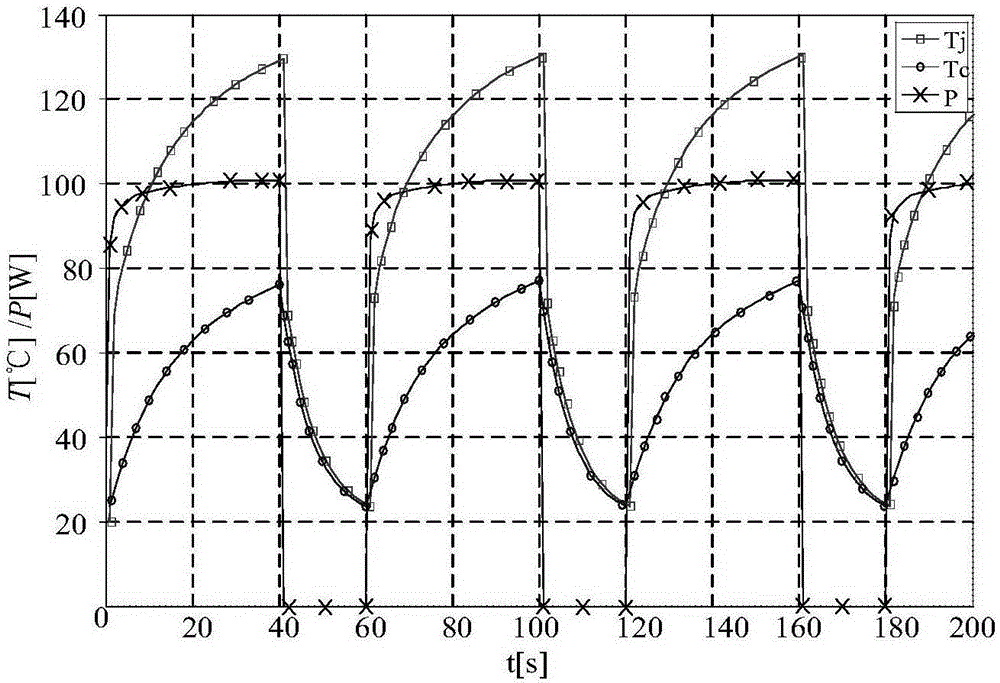

[0031] The present invention will be further described below in conjunction with accompanying drawing and embodiment: figure 1 It is a schematic diagram of the principle of the present invention, figure 2 It is a numerical simulation curve diagram of the comprehensive Foster thermal network power cycle impact process before the optimization of the radiator of the present invention, image 3 It is a numerical simulation curve diagram of the comprehensive Foster thermal network power cycle impact process after the radiator of the present invention is optimized, Figure 4 is the general calculation model of IGBT real-time junction temperature feedback loss of the present invention, Figure 5 It is a structural diagram of the heat sink thermal resistance test of the present invention.

[0032] like figure 1 As shown, the method for optimizing the dynamic response performance of power device radiators based on numerical iteration in this embodiment includes

[0033] a. Establi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com