Semiconductor device manufacture procedure prediction system and method

A prediction system and prediction method technology, applied in the semiconductor field, can solve the problems of increasing the cost of semiconductor devices, wafer abandonment, etc., and achieve the effect of preventing major reliability and/or yield problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

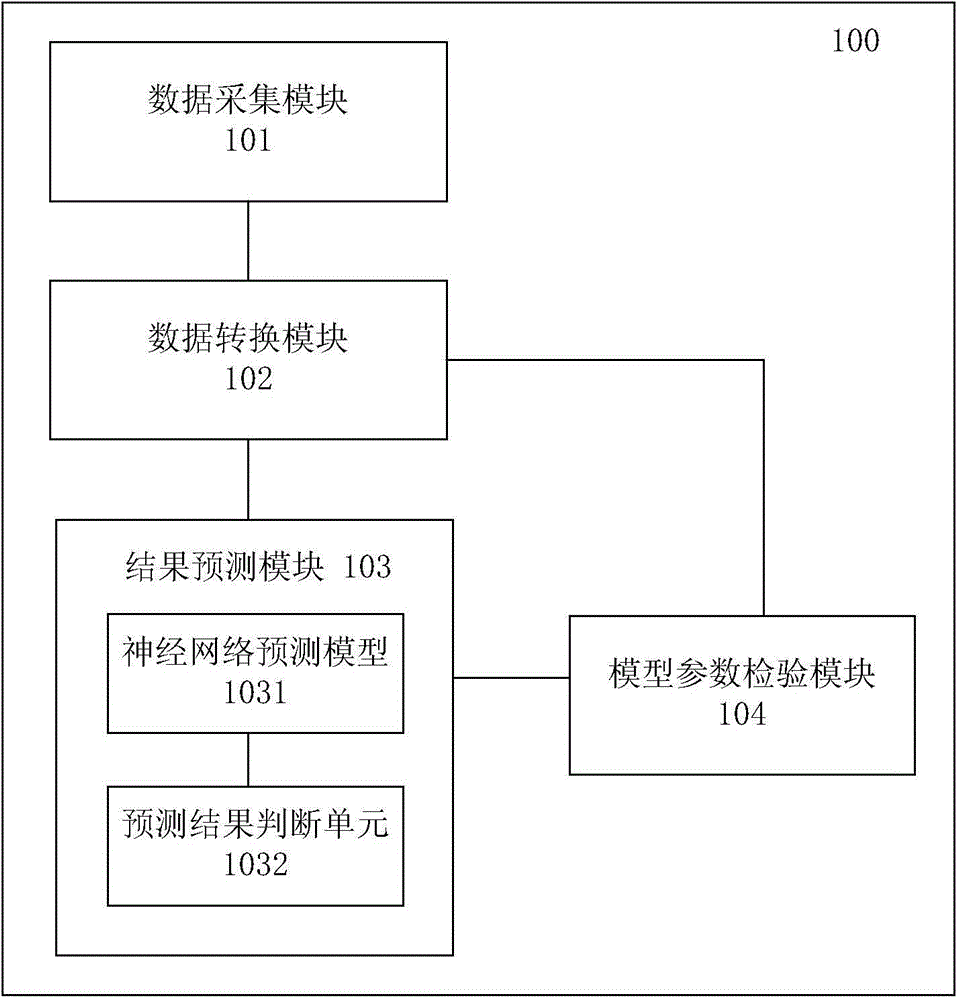

[0057] An embodiment of the present invention provides a semiconductor device manufacturing process prediction system, which can prevent major reliability and / or yield problems in the semiconductor device manufacturing process by collecting online data and predicting the results of the information to be predicted. Among them, the prediction of reliability and / or yield rate results is mainly realized by using a neural network model (NeuralNetworksModule).

[0058] Such as figure 1 As shown, this embodiment provides a semiconductor device manufacturing process prediction system 100 , which includes a data acquisition module 101 , a data conversion module 102 , and a result prediction module 103 . Wherein, the result prediction module 103 includes a neural network prediction unit 1031 and a prediction result judgment unit 1032 . In addition, the semiconductor device process prediction system 100 may further include a prediction unit parameter verification module 104 .

[0059] ...

Embodiment 2

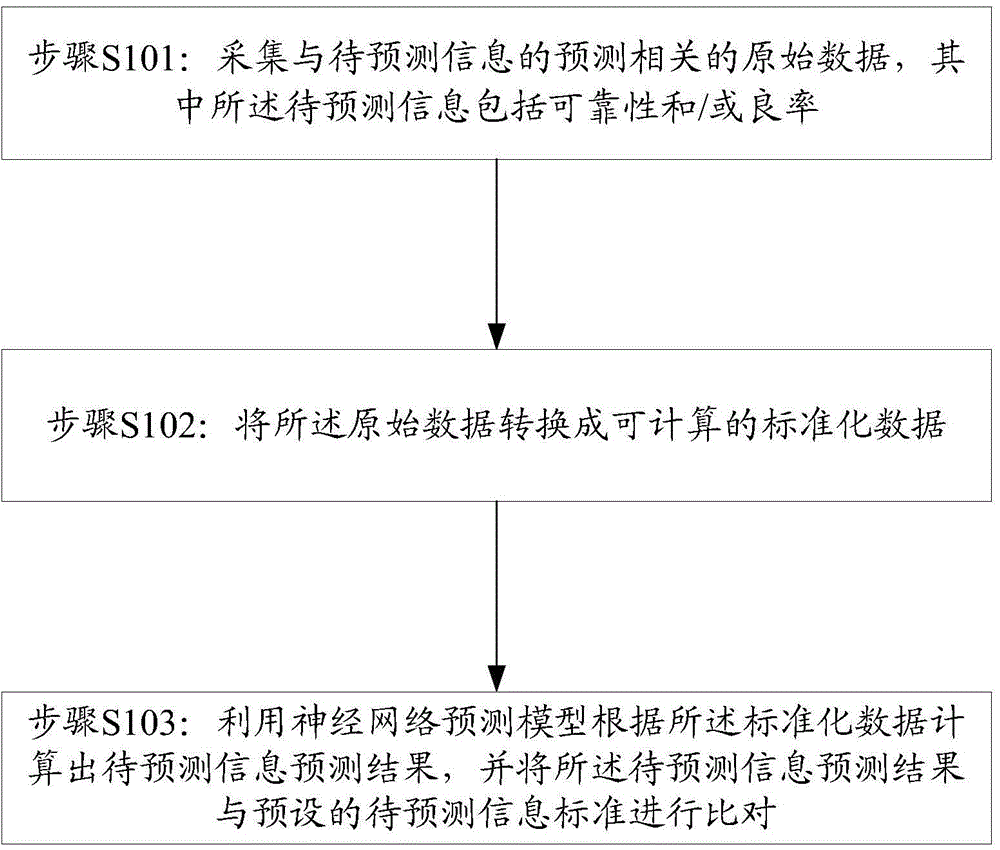

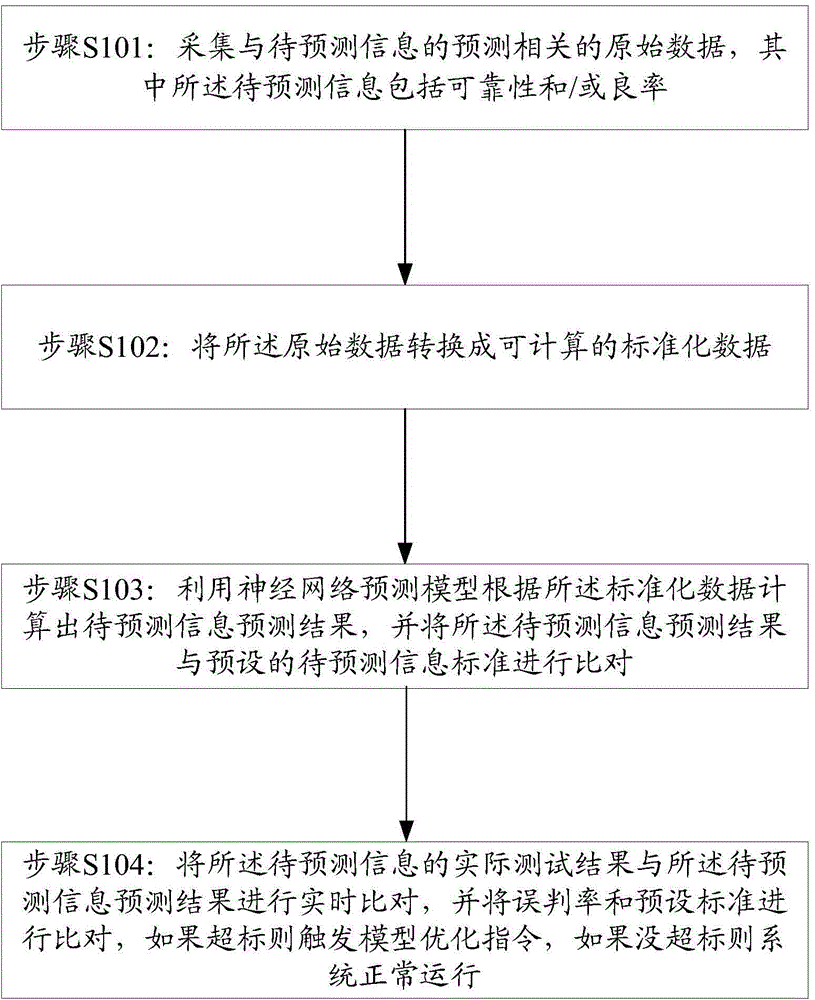

[0112] An embodiment of the present invention provides a semiconductor device manufacturing process prediction method, which is implemented by using the semiconductor device manufacturing process prediction system described in Embodiment 1. The semiconductor device manufacturing process prediction method can prevent major reliability and / or yield rate problems in the semiconductor device manufacturing process by collecting online data and predicting the results of the information to be predicted (reliability or yield rate). Among them, the calculation of the predicted result of the predicted information (such as reliability or yield rate) is mainly realized by using a neural network model.

[0113] Below, refer to figure 2 and image 3 The semiconductor device manufacturing process prediction method of this embodiment will be introduced. in, figure 2 It is a flowchart of a semiconductor device manufacturing process prediction method according to an embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com