Surface-mounted internal rotor permanent magnet synchronous motor with fast response

A permanent magnet synchronous motor, inner rotor technology, applied in synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problem of slow servo response, quadrature axis Problems such as slow current, to achieve the effect of accelerating torque response speed, speed servo response speed, and response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

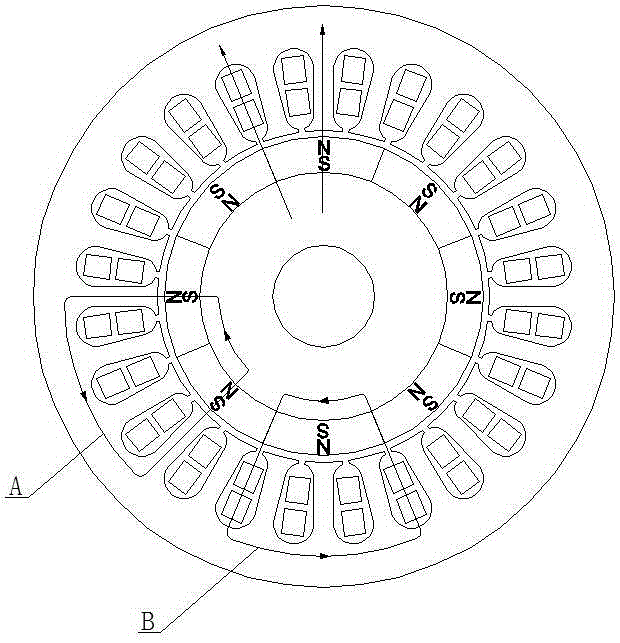

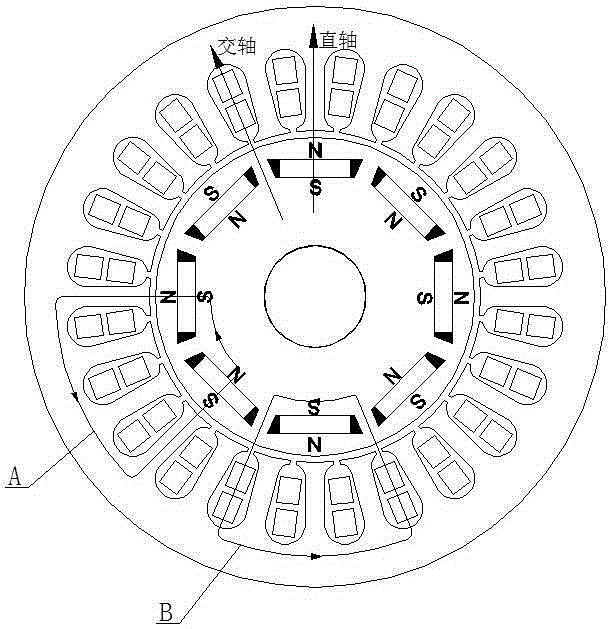

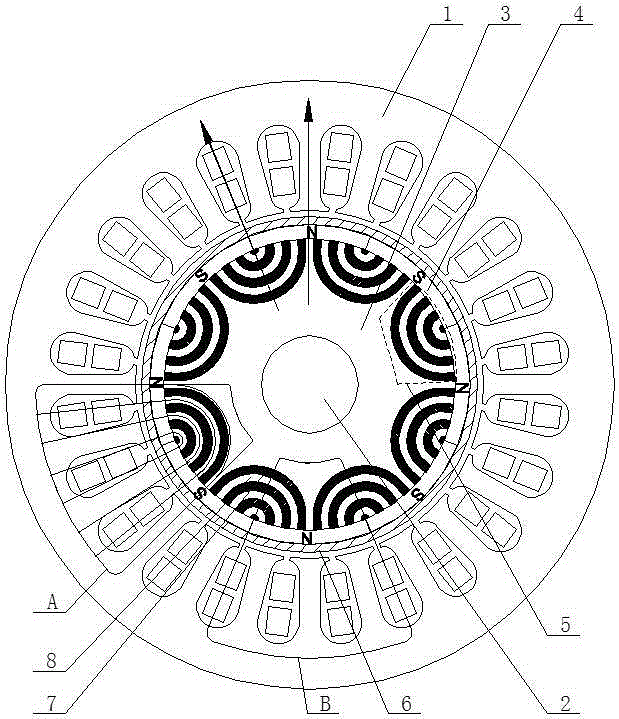

[0024] Specific implementation mode one: as image 3 with Figure 4 As shown, this embodiment describes a faster-response surface-mounted inner rotor permanent magnet synchronous motor, including an inner rotor and an outer stator 1, and the outer stator 1 is sleeved outside the inner rotor and between the two There is a gap, the inner rotor includes a rotating shaft 2, an iron core 3 and a plurality of permanent magnets 4, and the plurality of permanent magnets 4 are tile-shaped; the iron core 3 is fixedly sleeved on the rotating shaft 2, so The iron core 3 is provided with a plurality of slotted units 5 near the edge of the outer circumference. The plurality of permanent magnets 4 are arranged in sequence and are all pasted on the outer circumference of the iron core 3. The plurality of permanent magnets 4 are all diameter Direct or axial magnetization, every two adjacent permanent magnets 4 have opposite polarities (to establish a magnetic field with alternating N and S po...

specific Embodiment approach 2

[0025] Specific implementation mode two: as image 3 As shown in the specific embodiment 1 of the surface-mounted inner rotor permanent magnet synchronous motor with faster response, the outer peripheral surface of the inner rotor is fixed with a shielding sleeve 6 to protect the permanent magnet 4 .

specific Embodiment approach 3

[0026] Specific implementation mode three: as image 3 with Figure 4 As shown, in the surface-mounted inner rotor permanent magnet synchronous motor with faster response described in the first specific embodiment, each of the slotting units 5 includes a plurality of grooves, and the plurality of grooves are arc groove, trapezoidal groove, V-shaped groove or W-shaped groove. In order to facilitate processing.

[0027] The shape of each groove unit 5 is not limited to the several shapes listed above, and other shapes can also be used. The shape of the slot can be either the above-mentioned symmetrical slot structure per pole, or an asymmetric structure under each pole, such as a symmetrical slot structure under each pair of poles.

[0028] Symmetrical slotting method for each pole: such as Image 6 As shown, that is, the slot under one magnetic pole is symmetrical along the center line of this magnetic pole, and the left and right sides are respectively connected to the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com