Electric automobile power battery management system and method based on big data and used for battery gradient utilization

An electric vehicle and battery ladder technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of data loss and low battery data accuracy, and achieve the effect of avoiding waste, avoiding data loss and unified storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

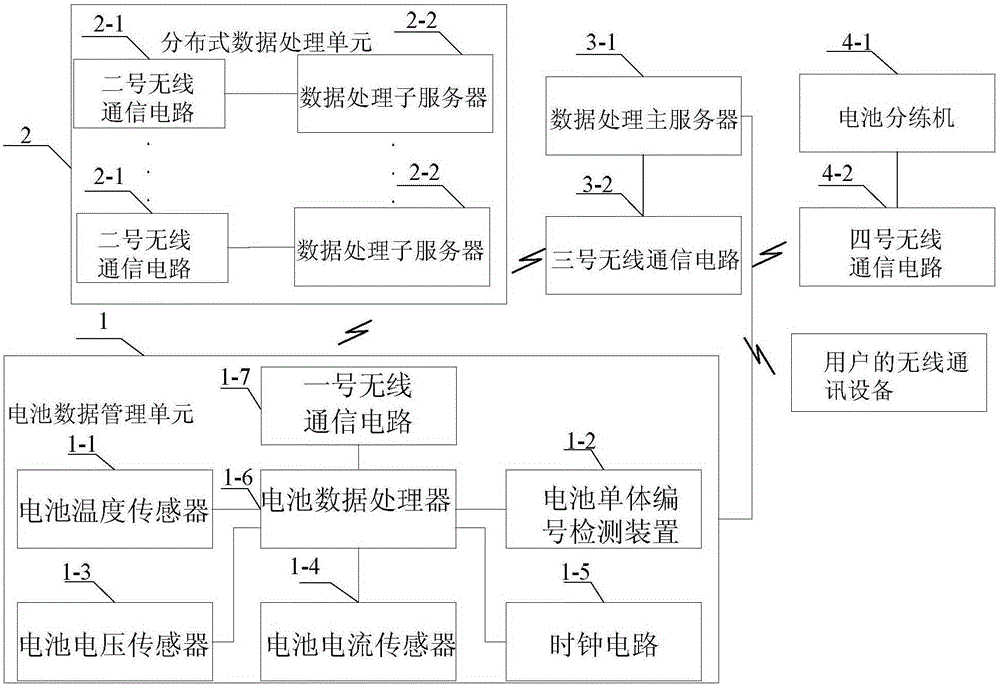

[0035] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the electric vehicle power battery management system for battery cascade utilization based on big data described in this embodiment, it includes a battery data management unit 1, a distributed data processing unit 2, and a data processing master server 3-1 , No. 3 wireless communication circuit 3-2, No. 4 wireless communication circuit 4-2 and battery training machine 4-1;

[0036] The battery data management unit 1 is arranged on the electric vehicle, and it includes a battery cell number detection device 1-2, a battery temperature sensor 1-1, a battery voltage sensor 1-3, a battery current sensor 1-4, a clock circuit 1-5, Battery data processor 1-6 and No. 1 wireless communication circuit 1-7;

[0037] The battery cell number detection device 1-2 is used to collect the number of each battery cell of the electric vehicle battery, and the battery number signal output terminal of the battery ...

specific Embodiment approach 2

[0044] Specific embodiment 2. This embodiment uses the battery management method of the electric vehicle power battery management system for cascade utilization of batteries based on big data described in specific embodiment 1. The method includes:

[0045] collection steps;

[0046] In this step, the number of the battery cells in the battery pack on the electric vehicle is detected by the battery cell number detection device 1-2,

[0047] The battery temperature sensor 1-1 collects the temperature in the battery pack on the electric vehicle,

[0048] The battery voltage sensor 1-3 collects the voltage signal output by the battery cell in the battery pack on the electric vehicle,

[0049] The battery current sensor 1-4 collects the current signal output by the battery cell in the battery pack on the electric vehicle;

[0050] And send the collected temperature signal of the battery pack on the electric vehicle, the voltage signal output by the battery cell, the current sign...

specific Embodiment approach 3

[0066] Specific Embodiment 3. This embodiment is a further description of the battery management method of the second specific embodiment using the electric vehicle power battery management system based on big data for battery cascade utilization. In this embodiment, the battery judgment Steps also include:

[0067] The main data processing server 3-1 determines whether the internal resistance of each battery cell is greater than the maximum internal resistance threshold P of the battery according to the received signal, and P is a positive number;

[0068] When the internal resistance of the battery cell is greater than the maximum internal resistance threshold P of the battery, the main data processing server 3-1 sends a low battery alarm signal to the wireless communication device of the user via the No. The battery cell number signal of the maximum internal resistance threshold P of the battery is sent out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com