Barium sulfate waste residue comprehensive utilization method and wall filling material

A filling material, barium sulfate technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as pollution and hinder the development of the barium salt industry, reduce production costs, reduce waste residue discharge, Good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

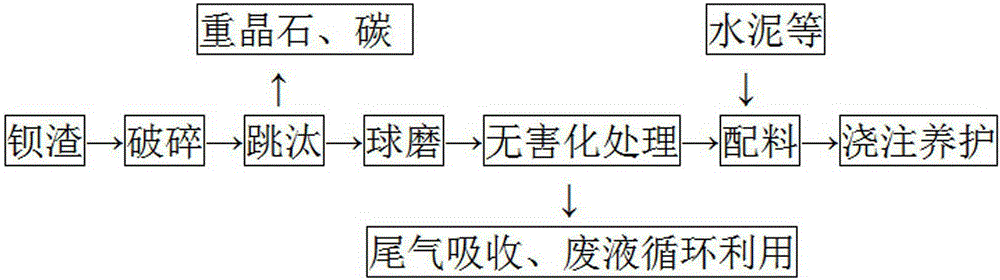

[0027] A kind of barium sulfate waste slag comprehensive utilization method, such as figure 1 shown, including the following steps:

[0028] (1) The newly produced barium sulfate slag is separated through a 5-mesh sieve, and the large particles that have not been burned through or the sintered symbionts that have not completely reacted in the barium slag are selected for peeling. At this time, the barium slag with larger particles accounts for 40%, and its barium sulfate content is about 35%.

[0029] After the large-grained barium slag is crushed and crushed, the particle size is controlled at 2-3 mm, and then it enters the jigging machine for jigging flotation, and a specific bed is selected according to the density of the recovered target object, and the bed particle size is controlled at 4-3 mm. Between 10mm (preferably 6-8mm), the bed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com