Polyurethane soft foam material for curing ballast bed and preparation method thereof

A polyurethane soft foam and ballast bed technology, applied in the field of catalysts, can solve problems such as environmental protection defects, inability to ensure ballast uniformity, prolong construction time, etc., and achieve excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

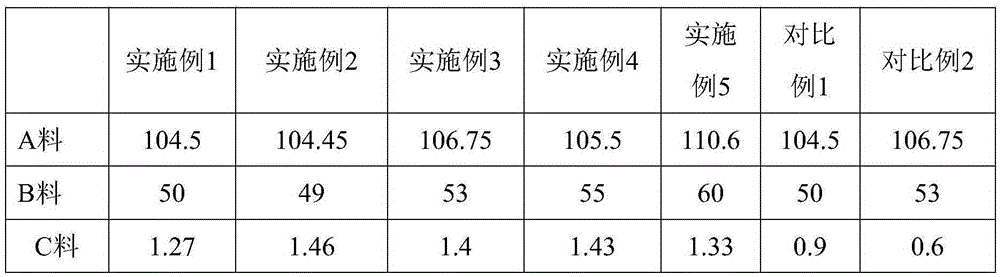

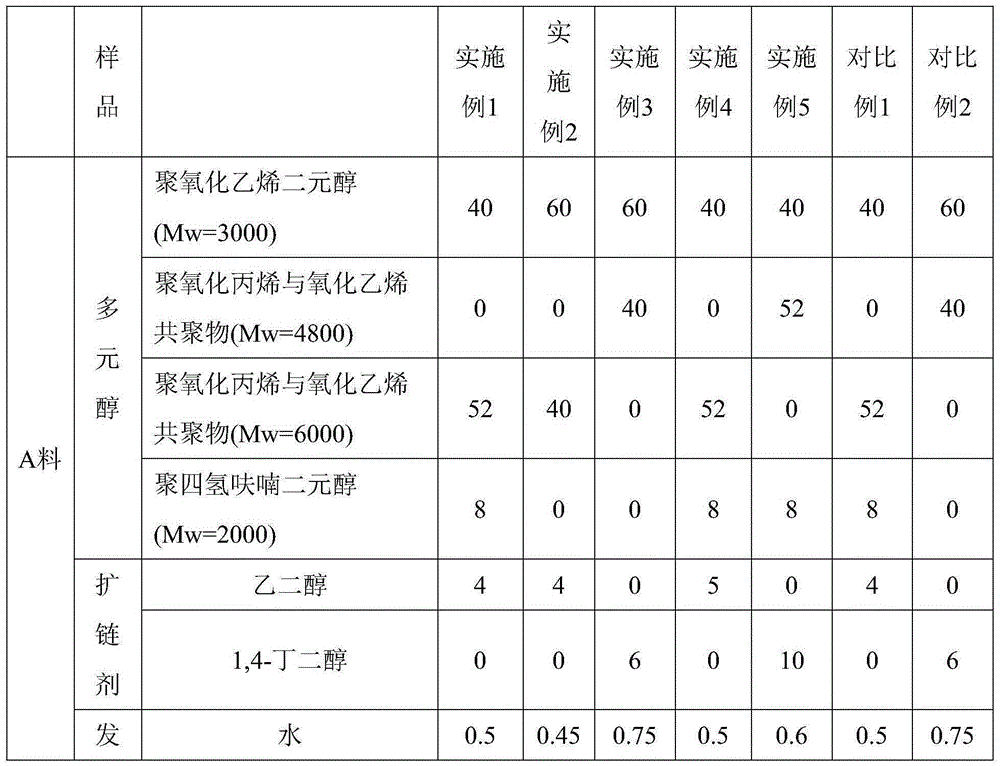

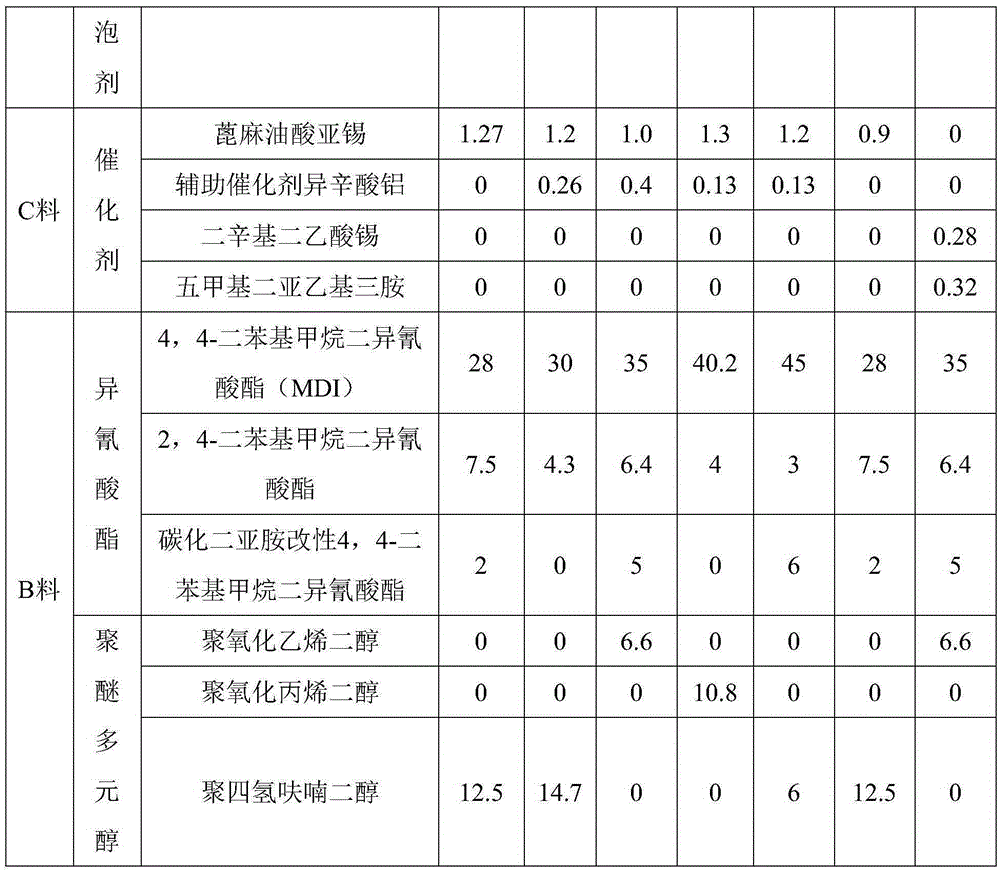

Examples

Embodiment 1 and 2

[0061] (1) Preparation of material A:

[0062] Stir polyether polyol and small molecule chain extender at a temperature of 60°C for 2 hours, then add foaming agent, continue stirring for 2 hours, and filter to obtain material A;

[0063] (2) Preparation of material B:

[0064] Every 30 minutes, add polyether polyol to isocyanate and mix, continue to react after adding, react at 90°C for 1 hour, filter to obtain material B;

[0065] (3) Premixing of material A and material C: mix the mixed material A and catalyst C in a separate material tank for use;

[0066] (4) Mix the mixture of material A and material C and material B uniformly through a high-pressure foaming machine to prepare a flexible polyurethane foam material.

Embodiment 3,4 and 5

[0068] (1) Preparation of material A:

[0069] Stir polyether polyol and small molecule chain extender at a temperature of 45°C for 3 hours, then add foaming agent, continue stirring for 3 hours, and filter to obtain material A;

[0070] (2) Preparation of material B:

[0071] Every 30 minutes, add polyether polyol to isocyanate and mix, continue to react after adding, react at 70°C for 3 hours, filter to obtain material B;

[0072] (3) Premixing of material A and material C: mix the mixed material A and catalyst C in a separate material tank for use;

[0073] (4) Mix the mixture of material A and material C and material B uniformly through a high-pressure foaming machine to prepare a flexible polyurethane foam material.

[0074] Comparative example 1 process condition is identical with embodiment 1, and comparative example 2 is identical with embodiment 3.

[0075] Molded sample preparation:

[0076] Adjust the temperature of material A and material B to (25±1)°C. Coat a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com