Liquid-crystal film plating oil and preparation method thereforLiquid-crystal film plating oil and preparation method therefor

A technology of coating oil and liquid crystal, applied in the direction of coating, can solve the problems of decomposition, deterioration and corruption, economic loss, etc., and achieve the effect of strong hydrophobicity, reduced contact area, and prolonged cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

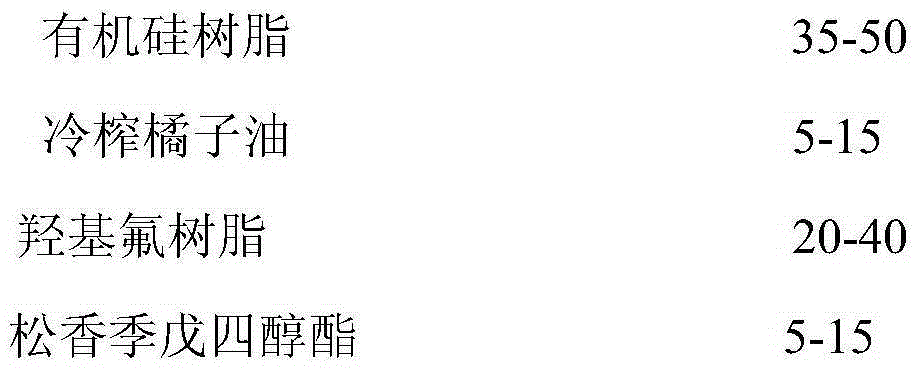

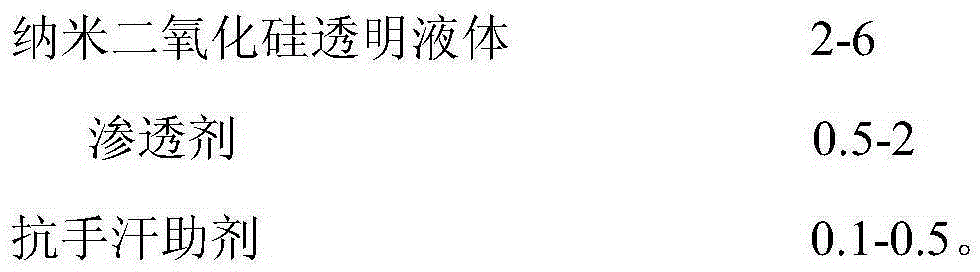

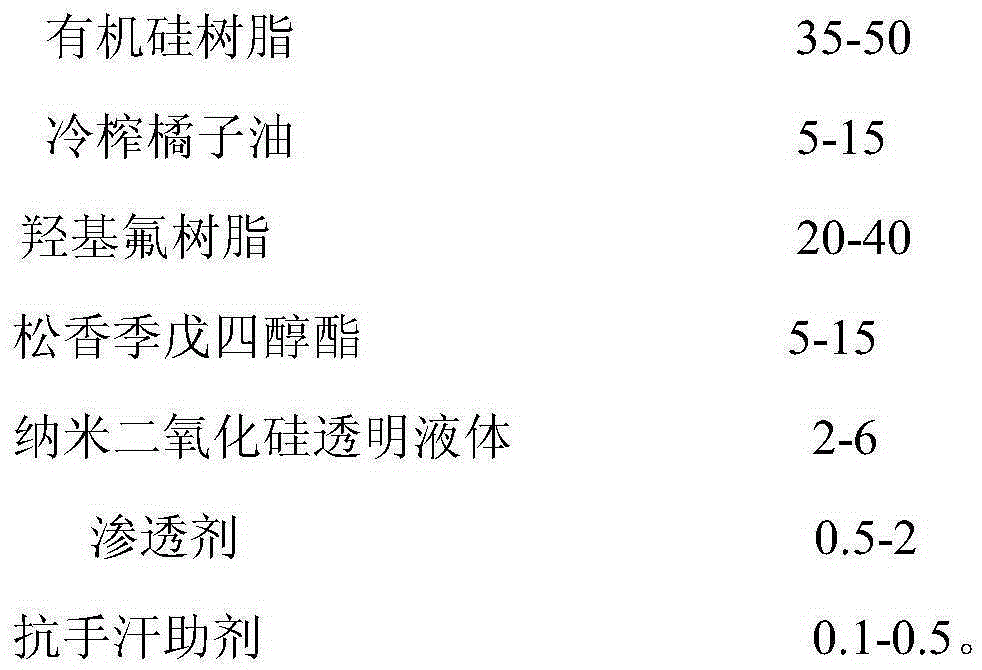

Method used

Image

Examples

Embodiment 1

[0036] ①Purchase a laboratory single-shaft high-speed dispersing machine in a factory workshop with the qualification to produce chemical products;

[0037] ②Make a circular dispersing cylinder with a suitable amount of 1000G;

[0038] ③Buy cold-pressed orange oil, hydroxyfluoro resin, rosin pentaerythritol ester, nano-silica transparent liquid, silicone resin, penetrating agent, anti-sweat additive (TEGO 435) in the market;

[0039] ④Clean the circular dispersion tank with alcohol and dry it;

[0040] ⑤Put 45 parts of silicone resin, 30 parts of hydroxyfluororesin, 10 parts of rosin pentaerythritol ester, 3.7 parts of nano-silica transparent liquid, 1 part of penetrant, and 0.3 parts of anti-hand sweat additive into the dispersion cylinder in proportion by weight. The order of feeding is not distinguished.

[0041] ⑥Disperse the material at a speed of 600-800RPM for 30 minutes, slowly add 10 parts of cold-pressed orange oil after dispersion, and adjust the viscosity to 10 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com