Emulsified oil and application thereof

An emulsified oil, animal and vegetable oil technology, applied in the field of emulsified oil, can solve problems such as adverse effects on the human respiratory system, achieve good emulsification stability, ensure engineering safety, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

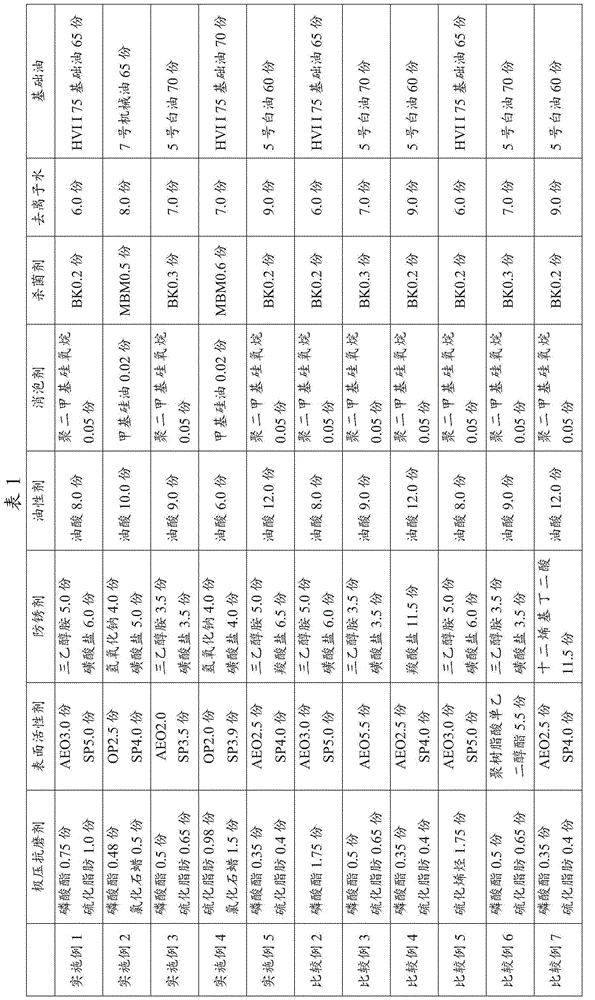

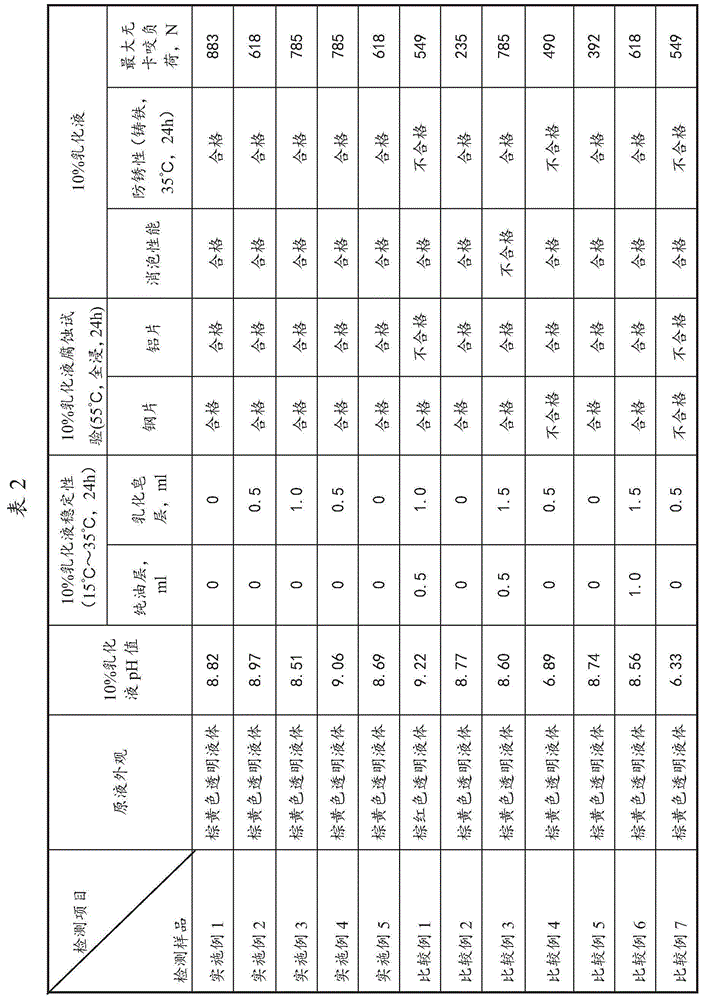

[0041] Put deionized water and inorganic alkali or alcohol amine antirust agent into the blending kettle, stir, heat up to 40℃ and maintain at this temperature; add oiliness agent and refined mineral oil, mix well; then add sulfonate antirust agent And surfactant, stir evenly; finally add extreme pressure antiwear agent, bactericide and defoamer in sequence, stir and stop heating, gradually cool down to room temperature, stop stirring, to obtain the emulsified oil. The types and amounts of each component in the emulsified oil are shown in Table 1.

[0042] In Table 1, AEO is fatty alcohol polyoxyethylene ether; SP is sorbitan fatty acid ester; OP is alkylphenol polyoxyethylene ether; BK is triazine bactericide; MBM is morpholine bactericide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com