Preparation method of low-conversion syrup of saccharose

A technology for inverting sugar syrup and sucrose, which is applied in the production of sucrose, sugar production, sugar products, etc., can solve the problems of difficult operation and poor flavor of syrup, and achieve the effects of simple operation, difficult crystallization and maintaining light flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of sucrose low invert syrup

[0050] (1) Take sucrose, stir and add it to 30°C warm water to make a 40°Bé sucrose solution;

[0051] (2) Add citric acid to adjust the pH to 4.5;

[0052] (3) Add invertase at the ratio of 0.05g per 1Kg of sucrose, put it in the infrared radiation reactor, select the infrared wavelength to be 1500-800cm -1 , Adjust the power of the infrared radiation reactor so that the temperature of the reaction solution is maintained at 30°C, and react for 30 minutes under the above conditions;

[0053] (4) Add malic acid to adjust the pH to 3.0, put it in a temperature-controlled microwave chemical reactor, quickly heat to 90-100°C, and keep it for 15 minutes;

[0054] (5) Add activated carbon to decolorize and filter;

[0055] (6) Cool to room temperature and get it.

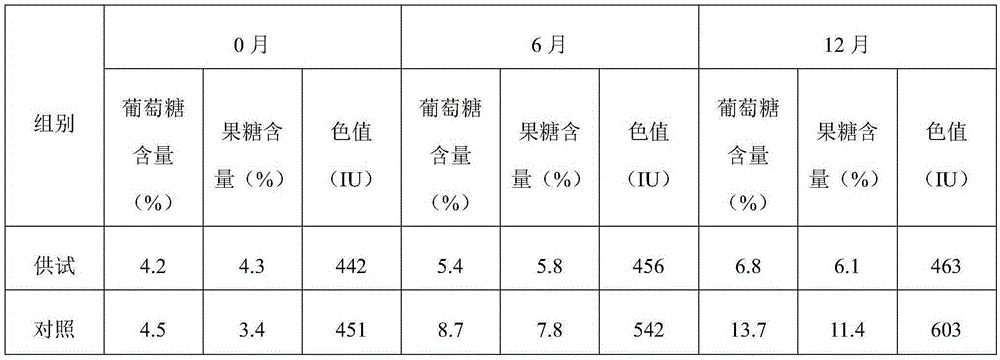

[0056] Stability test

[0057] The test method refers to Test Example 1, and the results are shown in the following table. The results show that the sucrose low invert syrup prepared by...

Embodiment 2

[0061] Preparation of sucrose low invert syrup

[0062] (1) Take sucrose, stir and add it to 60°C warm water to make a 65°Bé sucrose solution;

[0063] (2) Add citric acid to adjust the pH to 6.0;

[0064] (3) Add invertase at the ratio of 0.15g per 1Kg of sucrose, put it in the infrared radiation reactor, choose the infrared wavelength to be 1500-800cm -1 , Adjust the power of the infrared radiation reactor so that the temperature of the reaction solution is maintained at 50°C and react for 60 minutes under the above conditions;

[0065] (4) Add glucic acid to adjust the pH to 3.7, put it in a temperature-controlled microwave chemical reactor, quickly heat to 90-100°C, and keep it warm for 45 minutes;

[0066] (5) Add activated carbon to decolorize and filter;

[0067] (6) Cool to room temperature and get it.

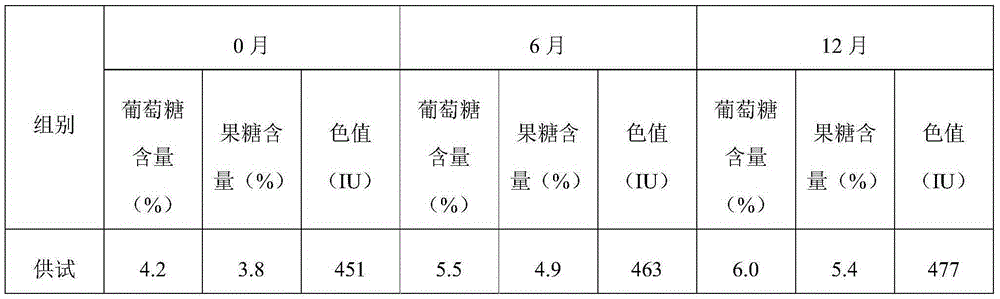

[0068] Stability test

[0069] The test method refers to Test Example 1, and the results are shown in the following table. The results show that the sucrose low invert syrup prepar...

Embodiment 3

[0073] Preparation of sucrose low invert syrup

[0074] (1) Take sucrose, stir and add it to 50°C warm water to make a 50°Bé sucrose solution;

[0075] (2) Add edible sour ingredients to adjust the pH to 5.0;

[0076] (3) Add invertase at the ratio of 0.10g per 1Kg of sucrose, put it in the infrared radiation reactor, select the infrared wavelength to be 1500-800cm -1 , Adjust the power of the infrared radiation reactor so that the temperature of the reaction liquid is maintained at 45°C, and react for 40 minutes under the above conditions;

[0077] (4) Add edible sour ingredients to adjust the pH to 3.5, put it into a temperature-controlled microwave chemical reactor, quickly heat to 90-100°C, and keep it warm for 30 minutes;

[0078] (5) Add activated carbon to decolorize and filter;

[0079] (6) Cool to room temperature and get it.

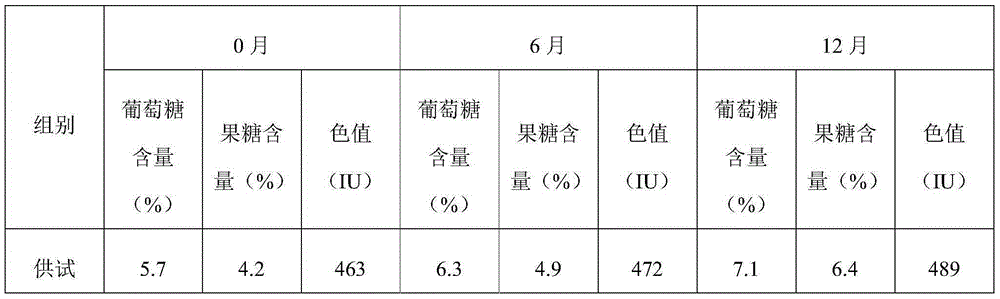

[0080] Stability test

[0081] See Test Example 1 for the test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com