High-strength vertical-fiber waterproof rock wool plate and production method thereof

A rock wool board, high-strength technology, applied in the direction of fire prevention, building components, building insulation materials, etc., can solve the problems of endangering personal safety, restricting the wide application of rock wool board for external wall insulation, and overall falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

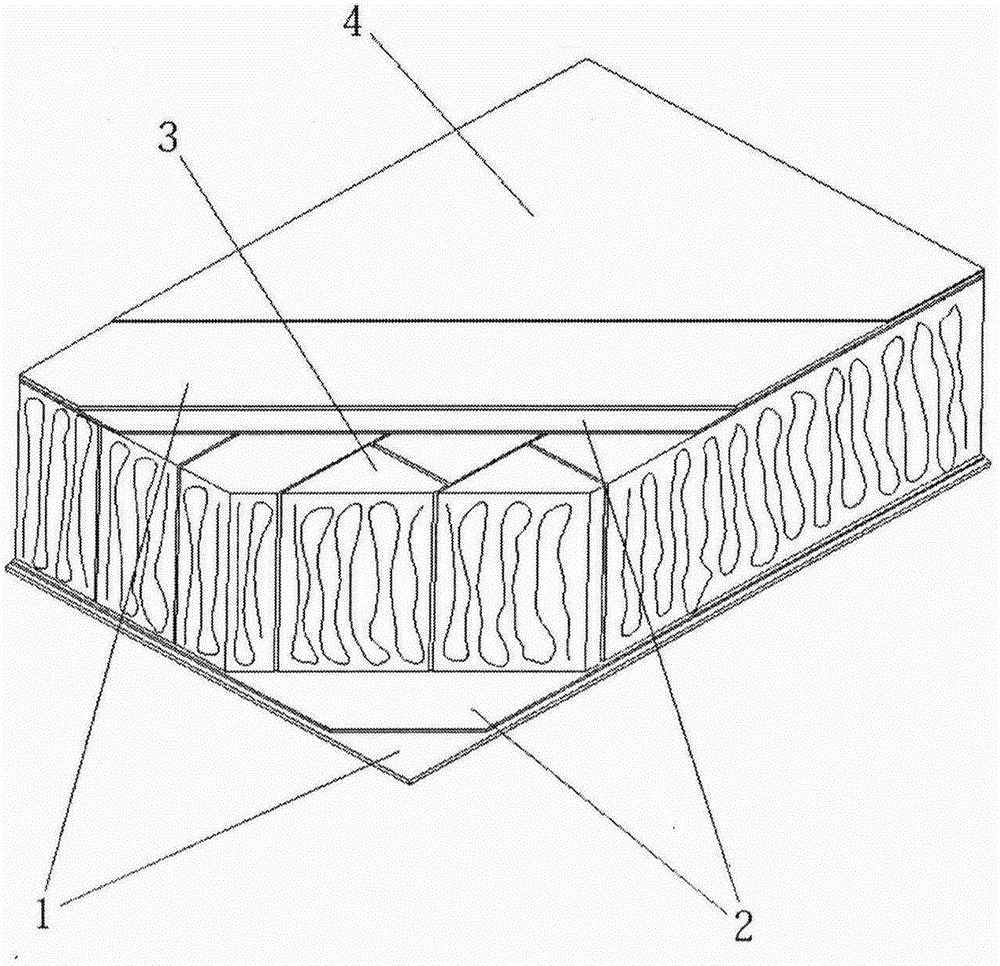

[0024] refer to figure 1 , a high-strength vertical thread waterproof rock wool board, including a vertical thread rock wool board 3, both sides of the vertical thread rock wool board 3 are compounded with an inorganic fireproof film 1, and the inorganic fireproof film 1 is bonded to the vertical thread rock wool board 3 by a quick adhesive 2 complex. Inorganic fireproof film 1 adopts thin glass fiber mat whose surface is permeated with inorganic silicon nanometer material water-insulating layer 4 .

[0025] The inorganic fireproof film layer of the product is a thin glass fiber mat whose surface penetrates the water-insulating layer 4 of inorganic silicon nanomaterials to form a water-insulating layer with a thickness of less than 1mm, which has excellent waterproof performance.

[0026] The vertical thread rock wool board 3 selected for the product has a bulk density of 100-140kg / m 3 Rock wool slats, the incisions are parallel to the surface and vertically staggered and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com