Fireproof partition laminate

A technology of partition layer and surface layer, applied in the direction of fire prevention, building components, construction, etc., can solve the problems of mildew, consumption of large wood, inability to cut off fire sources, etc., and achieve the effect of reducing use and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

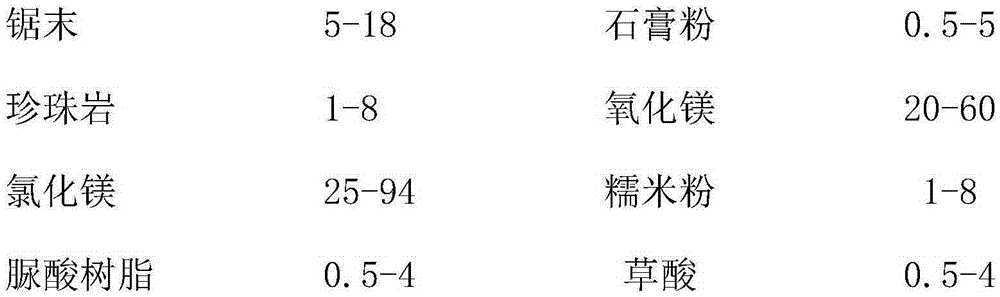

[0017] The fireproof partition laminate of the present invention includes a surface layer and a bottom layer made of glass fiber fabrics with a density of 70g / ㎡, and an inorganic mixture is filled between the surface layer and the bottom layer, wherein the inorganic mixture includes the following components :

[0018]

[0019] The method for manufacturing the fire-proof partition laminate of the present invention comprises the following steps:

[0020] A. Adjust the size of the mold machine tool according to the thickness of the specification; the thickness of the fireproof partition laminate can be 2 to 50mm, and the thickness of the fireproof partition laminate in this embodiment is 2mm, so adjust the size of the mold machine tool to the corresponding position;

[0021] B. First spread a layer of glass fiber fabric on the bottom of the mold machine tool; mix and stir the above components in proportion to prepare an inorganic mixture, pour the prepared inorganic mixture in...

Embodiment 2

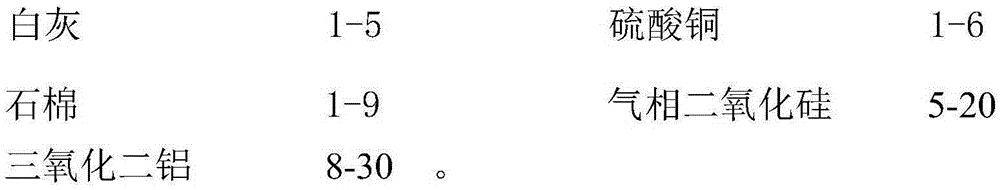

[0024] The fireproof partition laminate of the present invention includes a surface layer and a bottom layer made of non-woven fabrics with a density of 18g / ㎡, and an inorganic mixture is filled between the surface layer and the bottom layer, wherein the inorganic mixture includes the following components :

[0025]

[0026] The method for manufacturing the fire-proof partition laminate of the present invention comprises the following steps:

[0027] A. Adjust the size of the mold machine tool according to the thickness of the specification; the thickness of the fire-proof partition laminate can be 2 to 50mm, and the thickness of the fire-proof partition laminate in this embodiment is 5mm, so adjust the size of the mold machine tool to the corresponding position;

[0028] B. First spread a layer of non-woven fabric on the bottom of the mold machine tool; mix and stir the above-mentioned components in proportion to prepare an inorganic mixture, and pour the prepared inorgani...

Embodiment 3

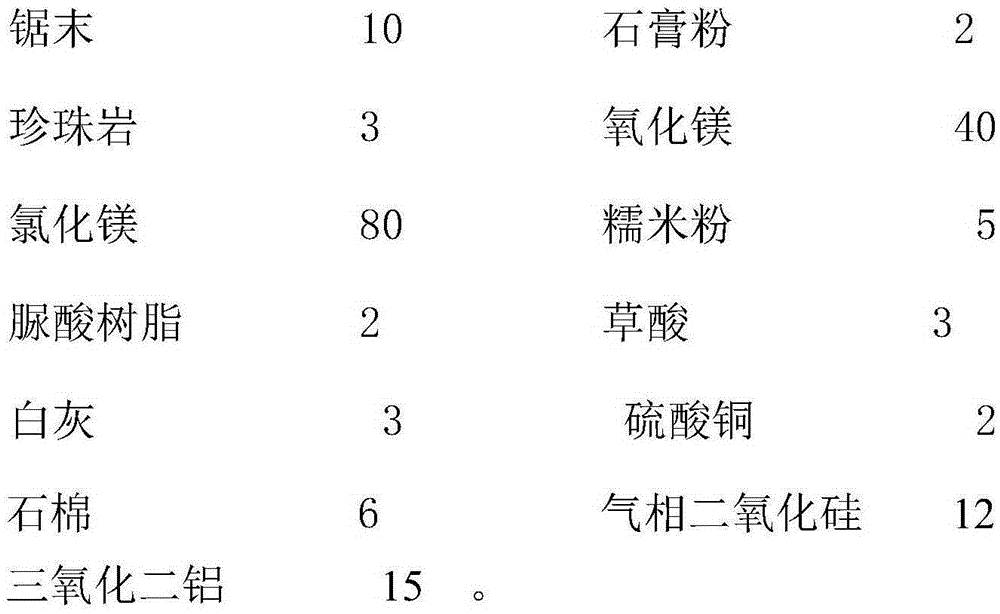

[0031] The fireproof partition laminate of the present invention comprises a surface layer made of glass fiber fabric with a density of 70g / ㎡ and a bottom layer made of non-woven fabric with a density of 18g / ㎡, and inorganic Mixture, wherein said inorganic mixture comprises the following components:

[0032]

[0033] The method for manufacturing the fire-proof partition laminate of the present invention comprises the following steps:

[0034] A. Adjust the size of the mold machine tool according to the thickness of the specification; the thickness of the fireproof partition laminate can be 2 to 50mm, and the thickness of the fireproof partition laminate in this embodiment is selected as 10mm, so adjust the size of the mold machine tool to the corresponding position;

[0035] B. First spread a layer of non-woven fabric on the bottom of the mold machine tool; mix and stir the above components in proportion to prepare an inorganic mixture, pour the prepared inorganic mixture i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com