Ceramic dust removal equipment for tobacco cutting and process

A technology for dust removal equipment and ceramics, which is used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. There are only 98% and other problems to achieve the effect of increasing the filling area, improving the application value and improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

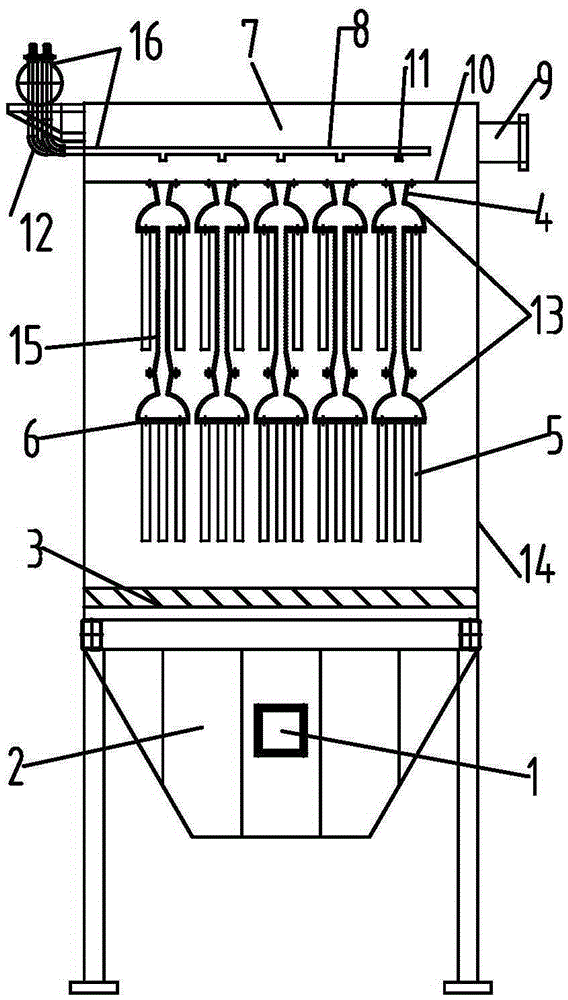

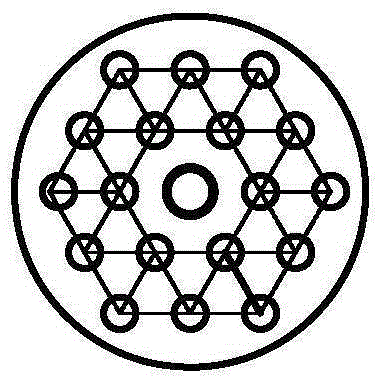

[0036] In this embodiment, a silicon carbide ceramic membrane tube 5 with an outer diameter of 35 mm, a length of 300 mm, and an average pore diameter of 20 μm is used as a filter element. The ceramic membrane integrated assembly 13 adopts a four-layer structure, and the silicon carbide ceramic membrane tube 5 uses asbestos as a sealing ring 6 . The inclination angle of the deflector 3 is 60 degrees, all the silicon carbide membrane tubes 5 are arranged in a triangle, and the distance between the centers of the membrane tubes is 60 mm. The dust concentration at the outlet of the dust collector is lower than 5mg / m 3 , The dust retention rate is greater than 99.9%, and the equipment resistance is less than 800Pa.

Embodiment 2

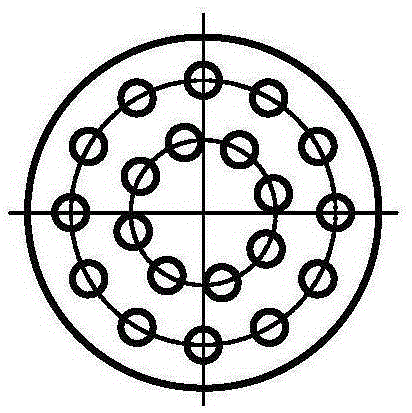

[0038] In this embodiment, a silicon carbide ceramic membrane tube 5 with an outer diameter of 60 mm, a length of 1500 mm, and an average pore diameter of 10 μm is used as a filter element. The ceramic membrane integrated assembly 13 adopts a two-layer structure, and the silicon carbide ceramic membrane tube 5 is sealed with a ceramic fiber felt. Circle 6. The inclination angle of the deflector 3 is 45 degrees, all the silicon carbide membrane tubes 5 are arranged in concentric circles, and the distance between the centers of the membrane tubes is 100 mm. The dust concentration at the outlet of the dust collector is lower than 3mg / m 3 , The dust retention rate is greater than 99.95%, and the equipment resistance is less than 1500Pa.

Embodiment 3

[0040] In this embodiment, an alumina ceramic membrane tube 5 with an outer diameter of 20 mm, a length of 450 mm, and an average pore diameter of 50 nm is used as a filter element. The ceramic membrane integrated module 13 adopts a three-layer structure, and the alumina ceramic membrane tube 5 uses graphite as a sealing ring. 6. The inclination angle of the deflector 3 is 30 degrees, the aluminum oxide membrane tubes 5 of the upper two membrane modules are arranged in a triangle, and the aluminum oxide membrane tubes 5 of the lower membrane module are arranged in concentric circles, and the distance between the centers of the membrane tubes is 40mm. The dust concentration at the outlet of the dust collector is lower than 1mg / m 3 , The dust retention rate is greater than 99.99%, and the equipment resistance is less than 5000Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com