Formalin liquid waste treatment system and method

A waste liquid treatment system, formalin technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that formalin waste liquid cannot be discharged directly problems, to achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

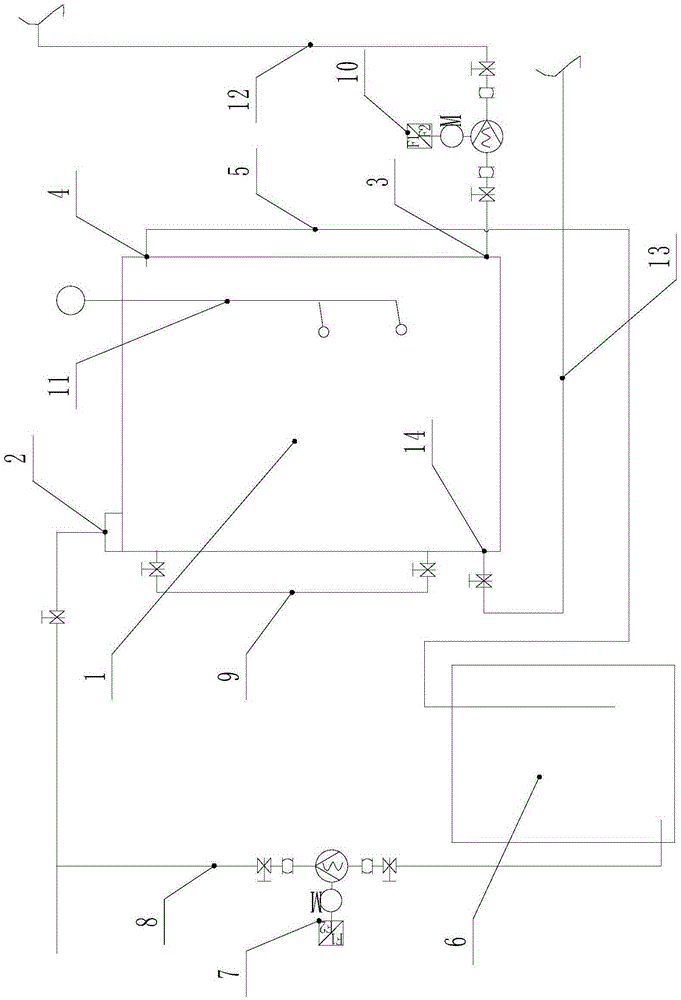

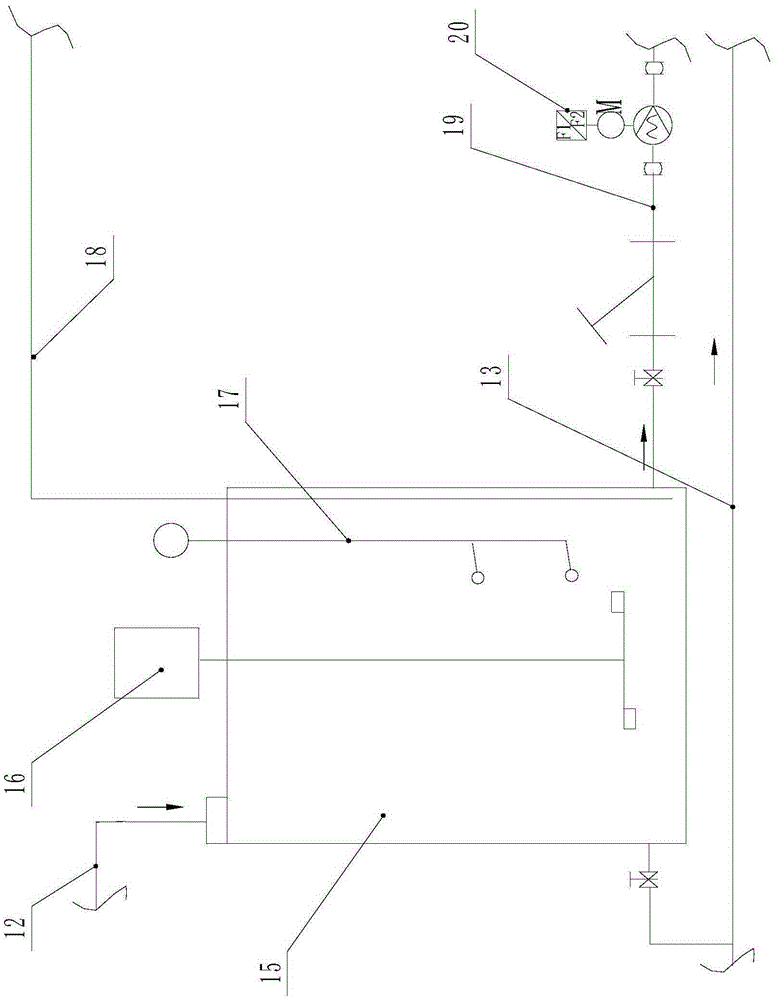

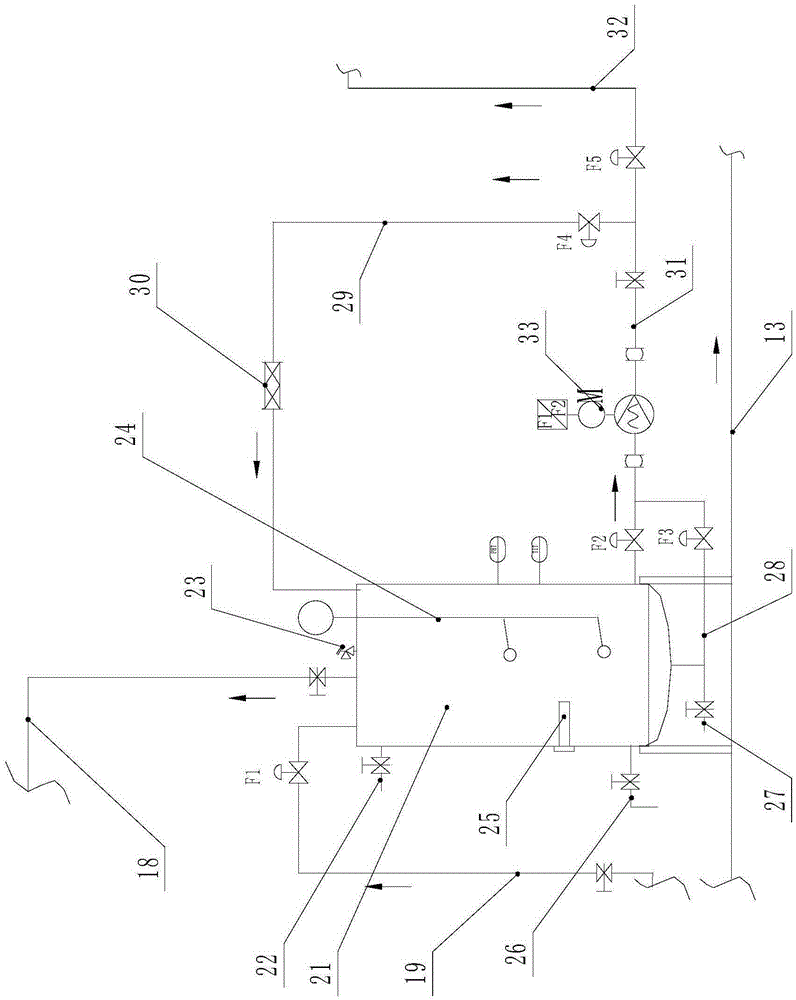

[0037] Such as Figure 1 to Figure 4 As shown, a formalin waste liquid treatment system, including

[0038] A collection storage tank 1 is provided with a first waste liquid inlet 2 and a first waste liquid outlet 3 on the collection storage tank 1, and the first waste liquid inlet 2 is communicated with a formalin waste liquid collection pipeline; The forest waste liquid collection pipe is directly connected to the sewage pipe of the formalin waste liquid discharge unit, for example, the formalin sewage pipes of hospitals and medical colleges are collected into the collection storage tank 1 . The bottom of the collection storage tank 1 is provided with a blowdown outlet 14, and a blowdown valve is installed at the blowdown outlet 14 and is connected with a blowdown pipeline 13 through the blowdown valve, and the blowdown pipeline 13 communicates with the blowdown system.

[0039] Such as figure 1 As shown, the top of the collection storage tank 1 is provided with an overflow ...

Embodiment 2

[0057] A kind of formalin waste liquid treatment method, it comprises the following steps:

[0058] A, the formalin waste liquid is uniformly collected in the collection storage tank 1;

[0059] B, the formalin waste liquid in the collection storage tank 1 is transported to the allocation box 15 for allocation, adding calcium hydroxide and polyacrylamide as catalyst and stirring and mixing, polyacrylamide: calcium hydroxide: the mol ratio of formaldehyde is 1:10 6 : 5×10 6 The addition time of calcium hydroxide and polyacrylamide is before the formalin waste liquid is transported to the mixing box 15.

[0060] C. Send the formulated formalin waste liquid to the polysaccharide reaction in the reaction tank 21, heat the formalin waste liquid in the reaction tank 21, the temperature rise rate is 0.5°C / min, stir and mix during the heating process, Stop heating when the temperature rises to 60°C, and keep warm for 60 minutes; the top of the reaction tank 21 is provided with a pr...

Embodiment 3

[0064] This embodiment is basically the same as Embodiment 2, except that the parameters are adjusted.

[0065] A kind of formalin waste liquid treatment method, it comprises the following steps:

[0066] A, the formalin waste liquid is uniformly collected in the collection storage tank 1;

[0067] B, the formalin waste liquid in the collection storage tank 1 is transported to the allocation box 15 for allocation, adding calcium hydroxide and polyacrylamide as catalyst and stirring and mixing, polyacrylamide: calcium hydroxide: the mol ratio of formaldehyde is 1: 3×10 6 : 20×10 6 The addition time of calcium hydroxide and polyacrylamide is before the formalin waste liquid is transported to the mixing box 15.

[0068] C. Send the formulated formalin waste liquid to the polysaccharide reaction in the reaction tank 21, heat the formalin waste liquid in the reaction tank 21, the temperature rise rate is 3°C / min, stir and mix during the heating process, Stop heating when the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com