A kind of odor-suppressing waste circuit board powder filled waste ABS regeneration composite material and its preparation method

A technology of composite materials and waste circuit boards, which is applied in the field of recycled composite materials, can solve problems such as restricting the scope of application, and achieve the effects of broad application prospects, improvement of difficult processing, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

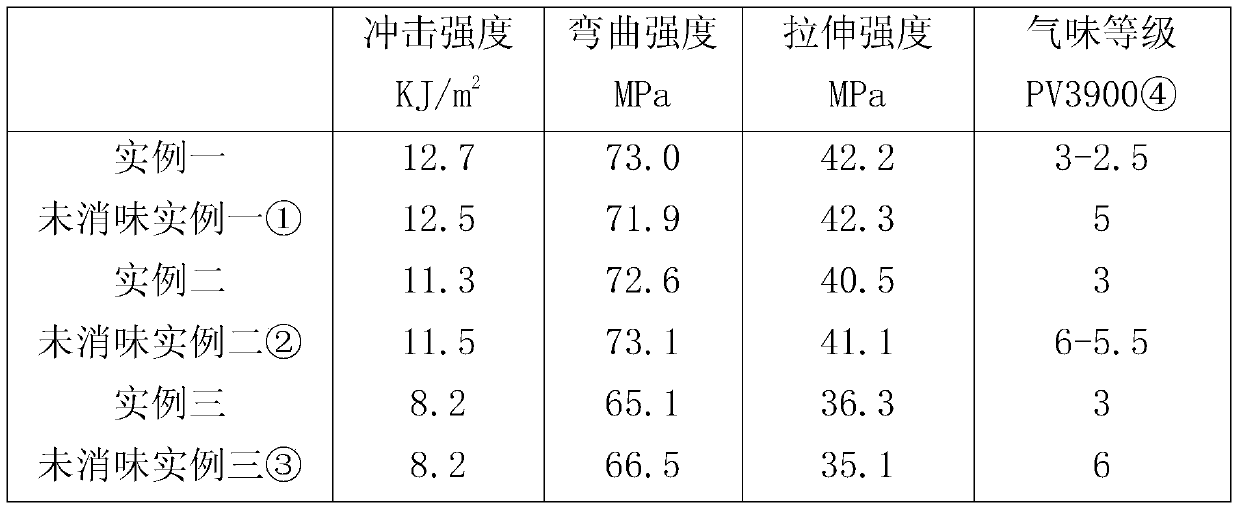

Examples

example 1

[0023] The waste circuit board is crushed and sieved to obtain a powder with a mesh size of more than 100. Then through static electricity and air separation, metal and non-metal powders are separated, and the non-metal powders are dried for use.

[0024] Zinc oxide, diatomaceous earth and zeolite are used as the odor inhibitor in a weight percentage ratio of 1:1:1. The pore size of zeolite is 0.3-1.0 nanometers. The preparation process of the odor inhibitor is as follows: activate the zinc oxide, diatomaceous earth and zeolite in a muffle furnace at 500° C. for 3 hours, take them out and place them in an odorless oven to cool for later use.

[0025] Mix the materials according to the following proportions by weight: 100 parts of waste ABS, 20 parts of non-metallic powder of waste circuit boards, 1 part of antioxidant, and 1 part of odor inhibitor. Wherein the antioxidant consists of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tris (...

example 2

[0029] The preparation method and steps are the same as in Example 1, and the material ratio is changed as follows: 100 parts of waste ABS, 50 parts of non-metallic powder of waste circuit board, 2 parts of antioxidant, and 3 parts of odor inhibitor.

[0030] Wherein the antioxidant consists of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tris (2,4-di-tert-butylphenyl) phosphite in a ratio of 1: 3 compounded.

[0031] Among them, the odor inhibitor is compounded by zinc oxide, aluminum oxide, diatomaceous earth and zeolite at a weight ratio of 0.5:0.5:1:1.

example 3

[0033] The preparation method and steps are the same as in Example 1, and the material ratio is changed as follows: 100 parts of waste ABS, 100 parts of non-metallic powder of waste circuit board, 1 part of antioxidant, and 5 parts of odor inhibitor.

[0034] Wherein the antioxidant consists of tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and tris (2,4-di-tert-butylphenyl) phosphite in a ratio of 1: 1 compounded.

[0035] The odor inhibitor is compounded by zinc oxide, aluminum oxide, magnesium oxide, diatomaceous earth and zeolite at a weight ratio of 0.5:0.25:0.25:1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com