Polyethylene composition for manufacturing lithium battery high-strength high-fusing temperature diaphragm

A lithium battery separator, high-density polyethylene technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of insufficient fusing temperature of polyethylene lithium battery separator, insufficient to maintain the safety of power lithium battery, etc. Excellent tensile properties and elongation at break, excellent mechanical properties, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

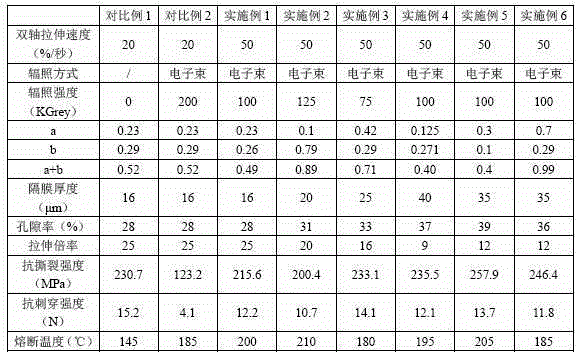

[0029] Mix 30 parts by weight of polyethylene material with 70 parts by weight of liquid paraffin, wherein the proportion of polyethylene material is per 100 parts by weight of polyethylene material, containing 10 parts by weight and the molecular weight is 7×10 6 The ultra-high molecular weight polyethylene resin, 70 parts by weight has a molecular weight of 3×10 6 The ultra-high molecular weight polyethylene resin, 18.5 parts by weight, the molecular weight is 7×10 5 High-density polyethylene resin, 1.5 parts by weight, molecular weight 6×10 4 The linear low density polyethylene resin. Extruded by a twin-screw extruder and salivated through a die into a 0.4mm thick film blank. After pre-extraction, stretching, extracting the diluent, shaping, and annealing, a 16μm thick lithium battery separator was prepared. See attached table 1 for specific stretching and irradiation process and film properties.

Embodiment 2

[0031] Mix 35 parts by weight of polyethylene material with 65 parts by weight of microporous filler oil, wherein the polyethylene material

[0032] The proportion of the material is per 100 parts by weight of polyethylene material, containing 1 part by weight of molecular weight 8×10 6 The ultra-high molecular weight polyethylene resin, 55 parts by weight has a molecular weight of 4.5×10 6 Ultra-high molecular weight polyethylene resin, 43.5

[0033] Parts by weight molecular weight is 4.5×10 5 High-density polyethylene resin, 0.5 parts by weight, molecular weight 4.0×10 4 The linear low density polyethylene resin. Extruded by a twin-screw extruder and salivated through a die into a 0.4mm thick film blank. After pre-extraction, stretching, extraction of diluent, shaping, annealing, and irradiation, a 20μm thick lithium battery separator was prepared. See attached table 1 for specific stretching and irradiation process and film properties.

Embodiment 3

[0035] Mix 15 parts by weight of polyethylene material with 85 parts by weight of white oil, wherein the proportion of polyethylene material is per 100 parts by weight of polyethylene material, containing 15 parts by weight and the molecular weight is 9×10 6 The ultra-high molecular weight polyethylene resin, 60 parts by weight has a molecular weight of 4×10 6 Of ultra-high molecular weight polyethylene resin, 23 parts by weight, molecular weight 8×10 5 Of high-density polyethylene resin, 2 parts by weight, molecular weight 8×10 4 The linear low density polyethylene resin. Extruded by a twin-screw extruder and salivated through a die into a 0.4mm thick film blank. After pre-extraction, stretching, diluent extraction, shaping, annealing, and irradiation, a 25μm thick lithium battery separator was prepared. See attached table 1 for specific stretching and irradiation process and film properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com