Spraying polyurea elastic coating and preparing method thereof

An elastic coating and polyurea technology, applied in the coating field, can solve problems such as blocking guns, and achieve the effect of solving foaming and ensuring storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A polyurea elastic coating for spraying, which is composed of component A and component B. The ratio of raw materials for component A is as follows: polyisocyanate 55% to 65%, polyether polyol 35% to 45%; component B The ratio of raw materials by mass percentage is as follows: amino-terminated polyether 45%-55%, amine chain extender 34-45%, multifunctional oxazolidine liquid water remover 5-10%, defoamer 0.5-1% , Dispersant 0.5-1%.

[0025] The polyisocyanate is selected from 4,4'-MDI (4,4'-diphenylmethane diisocyanate), 2,4'-MDI (2,4-diphenylmethane diisocyanate), PAPI (polymethylene At least one of base polyphenyl polyisocyanate), IPDI (isophorone diisocyanate), HMDI (dicyclohexylmethane-4,4'-diisocyanate).

[0026] The polyether polyol is at least one of the following substances with a number average molecular weight of 500-5000: polyoxypropylene polyol, polyacrylate polyol, polybutadiene polyol, polycarbonate polyol, polytetrahydrofuran ether polyol .

[0027] Mu...

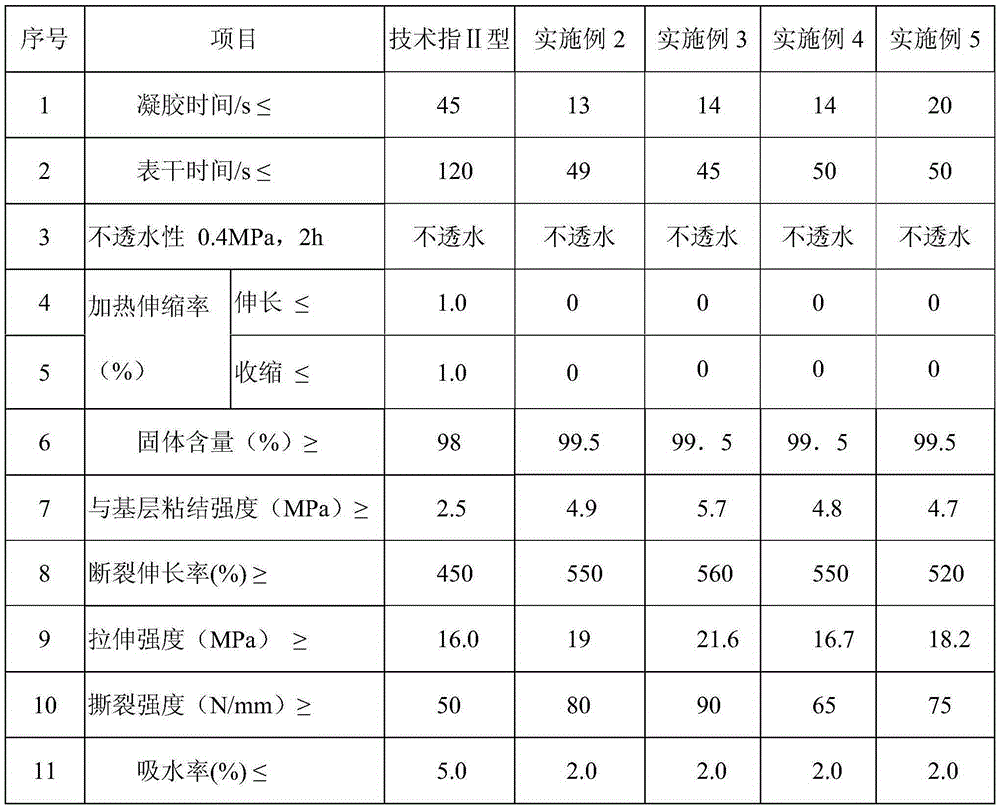

Embodiment 2

[0037] Same as Example 1, the difference is:

[0038]Polyisocyanate is preferably 4,4'-diphenylmethane diisocyanate in this embodiment, and its mass percentage is 55%; polyether polyol is preferably polyoxypropylene polyol 330N in this embodiment, and its mass percentage is 45% ; Multifunctional oxazolidine is preferably 2-isopropyl-3-hydroxyethyl-1,3-oxazolidine in this embodiment, and its mass percentage is 10%; amino-terminated polyether is preferred in this embodiment The mixture of polyetheramine JeffamineD1000 and polyetheramine JeffamineT5000, the mass percent of polyetheramine JeffamineD1000 is 30%, the mass percent of polyetheramine JeffamineT5000 is 25%; the amine chain extender is preferably diethyl toluene di Amine, its mass percentage is 34%; defoamer is EfkaSI2723, its mass percentage is 0.5%; dispersant is Efka4585, its mass percentage is 0.5%.

[0039] Because the coating prepared in Example 2 is in a uniform liquid state, the A component and the B component a...

Embodiment 3

[0041] Same as Example 1, the difference is:

[0042] The polyisocyanate is preferably a mixture of 4,4'-diphenylmethane diisocyanate and 2,4'-diphenylmethane diisocyanate in this embodiment, wherein the mass percentage of 4,4'-diphenylmethane diisocyanate is 35%, the mass percentage of 2,4'-diphenylmethane diisocyanate is 30%; polyether polyol is preferably polycarbonate polyol 1000D in this embodiment, its mass percentage is 35%; multifunctionality oxazole Alkanes are preferably di-2,2-dimethyl-N-hydroxyethyl-1,3-oxazolidinyl malonate in this embodiment, and its mass percentage is 8%; Among them, polyetheramine JeffamineD2000 is preferred, and its mass percentage is 45%; the amine chain extender is preferably 4,4'-bis-sec-butylaminodiphenylmethane in this embodiment, and its mass percentage is 45%; the defoamer is EfkaPB2001, its mass percentage is 1%; the dispersant is Efka5205, its mass percentage is 1%.

[0043] In Example 3, both component A and component B are in a un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com