Polyurethane self-healing rust coating with rust transformation and stabilization

A technology with rust coating and stabilization effect, applied in the field of coatings, can solve the problems of coating blistering, compatibility problems, high solubility, etc., and achieve the effect of good dispersion, compatibility and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

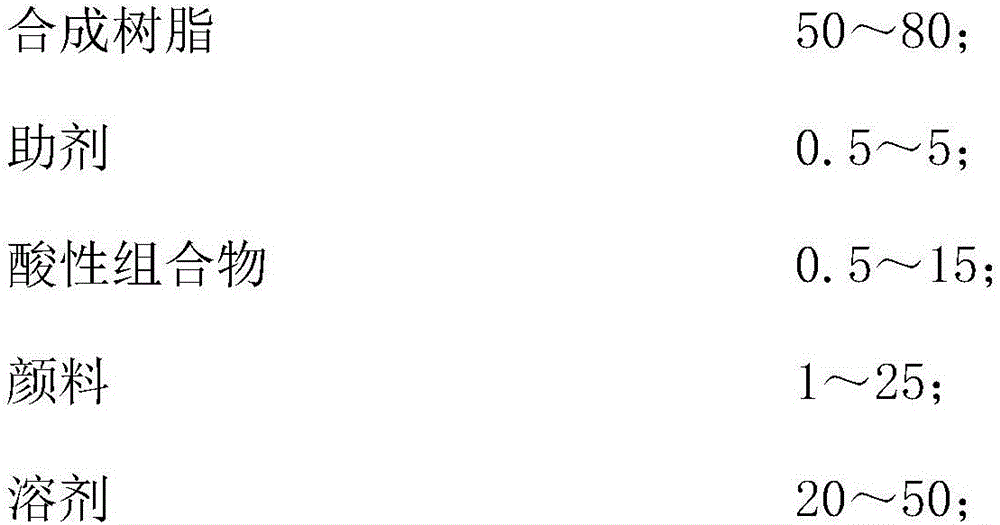

Method used

Image

Examples

preparation example Construction

[0030] Preparation of the coated acidic composition:

[0031] Add solvent to the reaction kettle, then add 0.6% ETERAC 7307-2-PM-70 resin of solvent quality, after mixing evenly, add metaphosphoric acid with 2% solvent amount, zinc dihydrogen phosphate with 1% solvent amount, 1% solvent amount Amount of phytic acid, stirred at 600rpm for 0.3h, then ground for 4h, after testing the fineness ≤ 40µm, took out the base material, then added 0.3% solvent quality 172N curing agent, stirred at 1000rpm for 0.5h. Then react at 70° C. for 3 h, and after cooling, centrifuge the obtained solid to perform solvent washing, spray drying at 70° C., and jet crushing to obtain the coated acidic composition.

[0032] Preparation of polyurethane self-repairing rust coating:

Embodiment 1

[0036] Add 64kg ETERAC 7307-2-PM-70 resin to the container, then add 0.5kg Disperbyk while stirring ® -110 dispersant, 0.5kg VISCOGEL ED anti-sedimentation agent, 14.5kg methyl ethyl ketone, 5.5kg of the above coating acidic composition and 15kg of titanium dioxide, stirred for 40 minutes; then these resin mixtures were ground to obtain the polyurethane self-repairing rust coating Component 1; dissolve 50kg 172N curing agent in 50kg butyl acetate in another container to make component 2 of polyurethane self-repairing rust coating; Component two is added to component one, and cured at room temperature for 7 days to form a polyurethane self-repairing rust coating.

Embodiment 2

[0038] Add 64kg ETERAC 7307-2-PM-70 resin to the container, then add 0.5kg Disperbyk while stirring ® -110 dispersant, 0.5kg VISCOGEL ED anti-settling agent, 18.8kg methyl ethyl ketone, 1.2kg of the above coating acidic composition and 15kg of titanium dioxide, stirred for 40 minutes; then these resin mixtures were ground to obtain the polyurethane self-repairing rust coating Component 1; dissolve 50kg 172N curing agent in 50kg butyl acetate in another container to make component 2 of polyurethane self-repairing rust coating; Component two is added to component one, and cured at room temperature for 7 days to form a polyurethane self-repairing rust coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com