A kind of polyurethane self-repairing rust coating and preparation method thereof

A self-repairing technology for rusty coatings, applied in the field of coatings, can solve problems such as coating foaming, achieve good dispersion and compatibility, and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

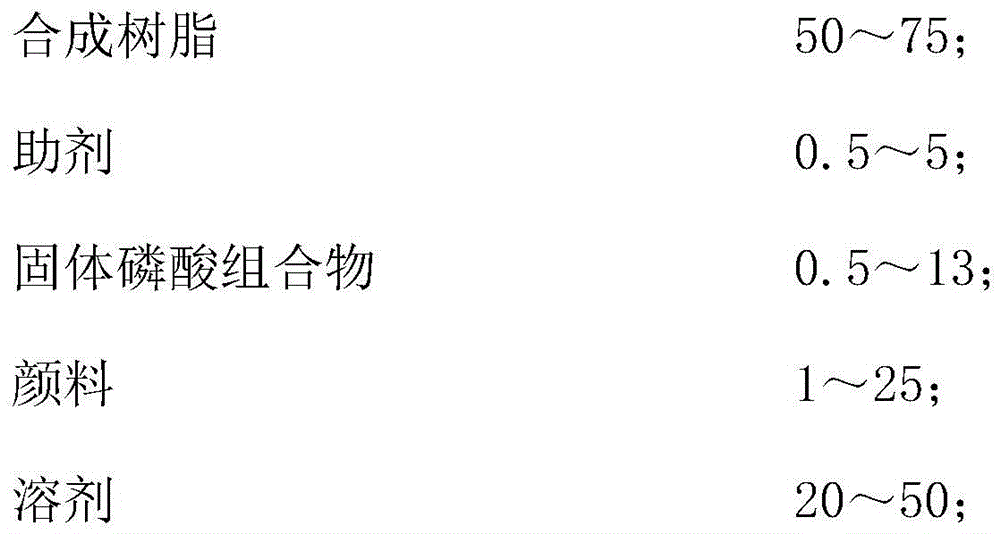

Method used

Image

Examples

preparation example Construction

[0032] Preparation of coated solid phosphoric acid composition:

[0033] Add 40kg of coupling agent, 40kg of metaphosphoric acid, and 40kg of zinc dihydrogen phosphate into the container, stir at 1100rpm for 0.5h, then put it into a ball mill and grind for 10h, until the fineness is 35 microns. The material is then filtered, dried at 100° C. for 6 hours, ground, and passed through a 325-mesh sieve to obtain a coated solid phosphoric acid composition.

[0034] Preparation of polyurethane self-repairing rust coating:

Embodiment 1

[0041] Add 63kg Desmophen680 resin (solid content 70%) into the reaction kettle, then add 0.3kg Disperbyk-107 dispersant, 0.3kg BORCHIGELTHIXOZ anti-settling agent, 14.1kg propylene glycol methyl ether acetate, 5.3kg above-mentioned coated solid phosphoric acid composition under stirring And 17kg titanium dioxide, stirred for 40 minutes.

[0042] These resin mixtures are ground again to obtain component 1 of the polyurethane self-repairing rust coating;

[0043] In another reaction kettle, dissolve 50kg DesmodurN75BA curing agent in 50kg methyl amyl ketone to make component two of polyurethane self-repairing rust coating;

[0044] According to the ratio of component 1: component 2 = 100:42, add component 2 to component 1, and cure at room temperature for 7 days to form a polyurethane self-repairing rust coating.

Embodiment 2

[0046] Add 63kg Desmophen680 resin (solid content 70%) into the reaction kettle, and then add 0.3kg Disperbyk-107 dispersant, 0.3kg BORCHIGELTHIXOZ anti-settling agent, 18.6kg propylene glycol methyl ether acetate, 0.8kg above-mentioned coated solid phosphoric acid combination under stirring thing and 17kg titanium dioxide, stirred for 40 minutes.

[0047] Grinding the above-mentioned resin mixture to obtain component 1 of the polyurethane self-repairing rust coating;

[0048]In another reaction kettle, dissolve 50kg DesmodurN75BA curing agent in 50kg methyl amyl ketone to make component two of polyurethane self-repairing rust coating;

[0049] Add component two to component one according to the ratio of component one: component two = 100:42, and cure for 7 days at room temperature to form a polyurethane self-repairing rust coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com