A kind of epoxy self-repairing rust coating and preparation method thereof

A kind of rusty coating and epoxy technology, which is applied in the coating field, can solve the problems of easy foaming and coating failure of the coating, and achieve the effect of good dispersion, compatibility and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

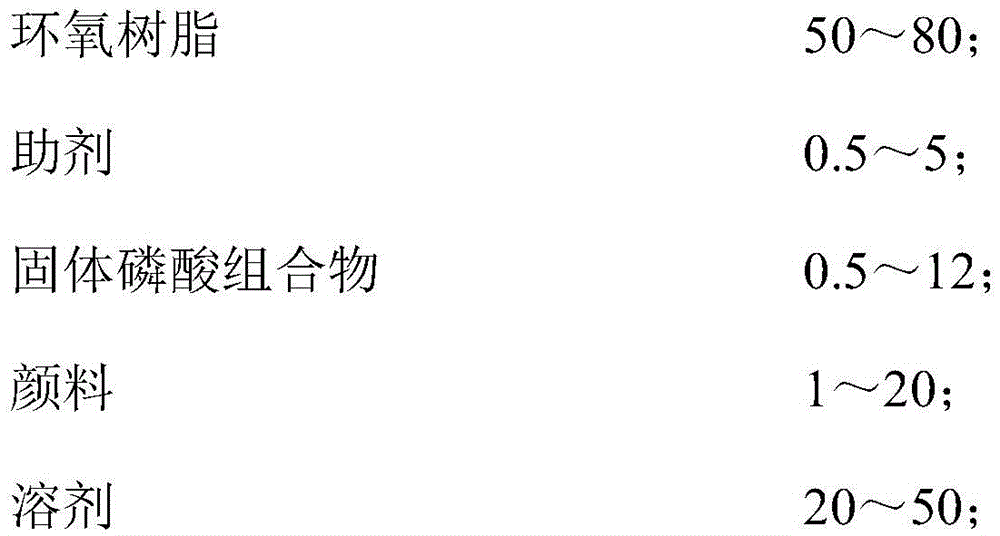

Method used

Image

Examples

preparation example Construction

[0032] Preparation of coated solid phosphoric acid composition:

[0033] Add 40kg of coupling agent, 40kg of metaphosphoric acid, and 20kg of manganese dihydrogenphosphate into the reaction kettle, and stir for 0.5h at a rotational speed of 1200rpm. Then put it into a ball mill and grind for 10 h until the fineness reaches 38 microns. The material is then filtered, dried at 90° C. for 8 hours, ground, and passed through a 325-mesh sieve to obtain a coated solid phosphoric acid composition.

[0034] Preparation of epoxy self-repairing rust coating:

Embodiment 1

[0038] Add 4.5kg of the above-mentioned coated solid phosphoric acid composition to the reactor under stirring, then add 64kg of E20 epoxy resin (solid content 75%), 0.5kg of Disperbyk ® -160 dispersant, 0.5kg JF-38 anti-sedimentation agent, 15.5kg xylene and 15kg titanium dioxide, stirred for 40 minutes; then these epoxy resin mixtures were ground to obtain component 1 of epoxy self-repairing rust coating; Dissolve 50kg 8115 polyamide resin curing agent in 50kg toluene in another reaction kettle to make component two of epoxy self-repairing rust coating; Divide into two parts and add to component one, and cure for 7 days at room temperature to form an epoxy self-repairing rust coating.

Embodiment 2

[0040] Add 0.8kg of the above-mentioned coating solid phosphoric acid composition to the reactor under stirring, then add 64kg of E20 epoxy resin (solid content 75%), 0.5kg of Disperbyk ® -160 dispersant, 0.5kg JF-38 anti-sedimentation agent, 19.2kg xylene and 15kg titanium dioxide, stirred for 40 minutes; then these epoxy resin mixtures were ground to obtain component 1 of epoxy self-repairing rust coating; Dissolve 50kg 8115 polyamide resin curing agent in 50kg toluene in another reaction kettle to make component two of epoxy self-repairing rust coating; Divide into two parts and add to component one, and cure for 7 days at room temperature to form an epoxy self-repairing rust coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com