Size groove for slasher and application method of size groove

A technology of sizing machine and sizing tank, which is applied in textiles and papermaking, liquid/gas/steam textile material processing, textile material processing, etc. It can solve the problems of product quality and grade degradation, inability to sizing slurry, poor heating effect, etc. problems, to achieve the effect of improving quality and grade, preventing sticking and agglomeration, and heating evenly and quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

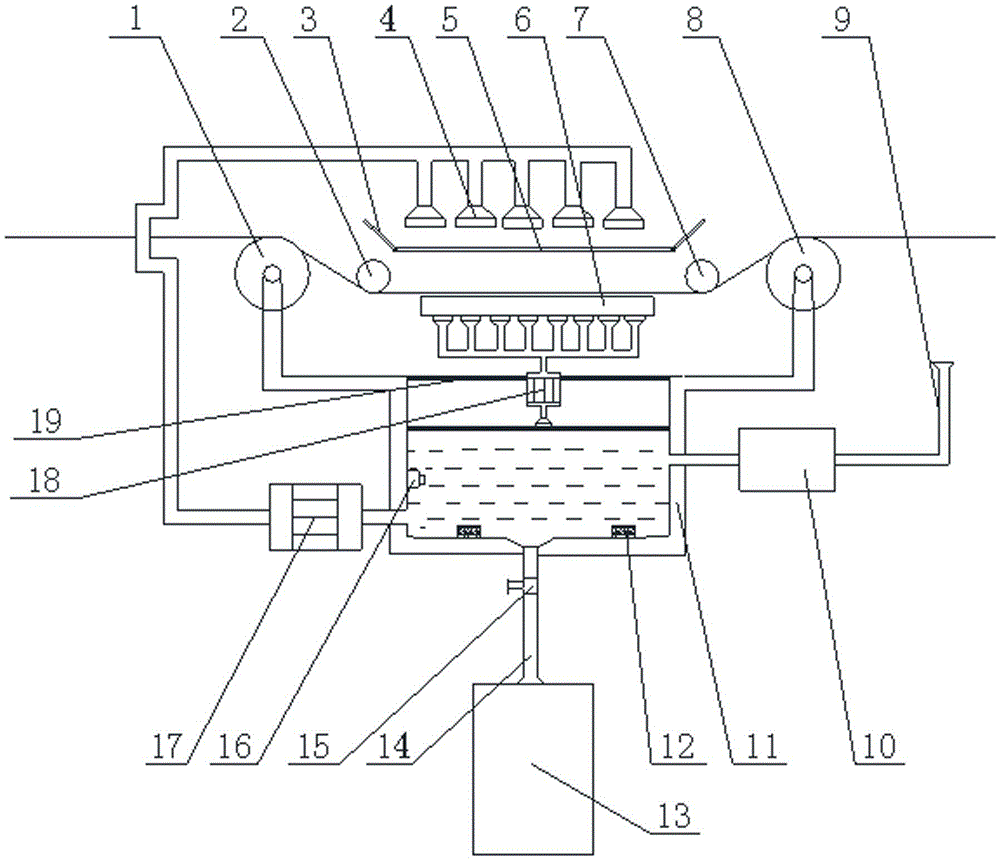

[0032] The sizing machine of the present embodiment uses the sizing tank, as figure 1 As shown, it includes a pulp tank 11, a DC power supply (not shown in the figure), a pulp inlet pipe 9 and a pulp discharge pipe 14. A temperature sensor 16 is installed in the pulp tank 11, and the DC power supply is installed near the pulp tank 11. The pulp tank 11 is provided with two microwave generators 12, the upper opening of the stock tank 11, the opening of the stock tank 11 is provided with two layers of metal mesh cover 19, the pulp inlet pipe 9 communicates with the front of the pulp tank 11, and the pulp feed pipe 9 and the pulp tank 11 is provided with preheating box 10. The slurry discharge pipe 14 communicates with the bottom of the slurry tank 11, and the slurry discharge pipe 14 is provided with a valve.

[0033] A front guide roller 1 is arranged on one side edge of the pulp tank 11, a front pressure roller 2 is arranged near the front guide roller 1 above the pulp tank 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com